Rubber floor gluing and laying device

A technology for rubber flooring and gluing, applied in construction and building construction, etc., can solve the problems of manual cutting safety hazards, low efficiency of rubber flooring, soiling of even numbers and clothes, etc., so as to avoid the need for manual manual cutting and improve laying. The effect of efficiency

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

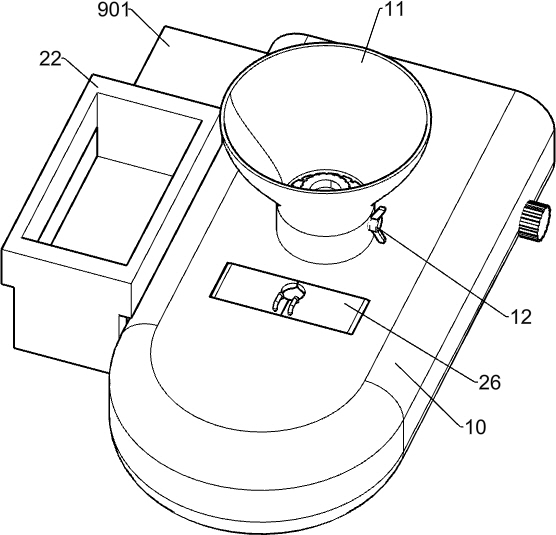

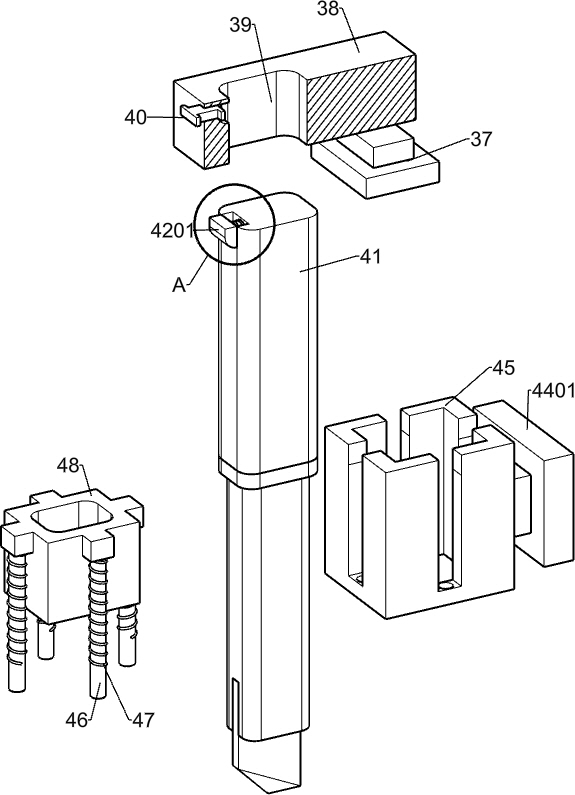

[0026] A kind of glue laying rubber floor device, such as figure 1 , figure 2 , image 3 , Figure 4 , Figure 6 and Figure 7As shown, it includes a laying platform 1, a power motor 4, a first gear 5, a second gear 6, a first unloading shaft 7, a second unloading shaft 8, a pressing shaft 9, an connecting plate 901, and a gluing table 10 , connecting rod 1001, rubber storage barrel 11 and glue control valve 12, four rollers for moving are installed at the bottom of laying platform 1, and there is a discharge trough 2 on the laying platform 1, which is used to place the rolled For rubber flooring, laying platform 1 is provided with a feeding chute 3, the feeding chute 2 is connected to the feeding chute 3, the rubber floor extends from the feeding chute 2 to the lower chute 3, and the left side wall of the laying platform 1 is equipped with a power Motor 4, the first gear 5 is fixedly connected on the rotating shaft of power motor 4, the second gear 6 is rotationally con...

Embodiment 2

[0029] On the basis of Example 1, such as Figure 5 and Figure 6 As shown, it also includes a squeegee adjustment assembly. The squeegee adjustment assembly includes an adjustment shaft 13, an adjustment gear 14, an adjustment knob 15, an adjustment clamp 16, a squeegee plate 17 and a gathering plate 18. There is an adjustment shaft 13, and the adjustment shaft 13 is slidingly connected with the gluing table 10 at the same time, the distance that the adjustment shaft 13 can slide to the right is greater than the thickness of the adjustment gear 14, and the left side and the middle part of the adjustment shaft 13 are fixedly connected with the adjustment gear 14, so that When the adjustment shaft 13 rotates, it can drive the adjustment gear 14 to rotate. The right side of the adjustment shaft 13 is affixed with an adjustment knob 15, and the gluing table 10 is affixed with an adjustment clamp 16. When the adjustment knob 15 is manually pulled to the right, the adjustment The ...

Embodiment 3

[0032] On the basis of Example 2, such as figure 1 , Figure 4 and Figure 6 As shown, it also includes a grinding and dust collection assembly, which includes a grinding motor 19, a grinding disc 20, a grinding ball 21, a placement plate 22, a vacuum cleaner 23, a dust suction head 25 and a cover plate 26. Grinding motor 19 is installed, and the rotating shaft of grinding motor 19 is fixedly connected with grinding disc 20, can drive grinding disc 20 to rotate thereby when the rotating shaft of grinding motor 19 rotates, and a plurality of grinding balls 21 are fixedly connected on grinding disc 20, and grinding motor 19 The rotation of the grinding disc 20 can be driven to rotate, and the uneven bottom surface can be polished by the grinding ball 21 on the grinding disc 20, thereby avoiding the impact of the uneven ground on the laying of the rubber floor. The connecting plate 901 is fixed with a placement plate 22. A vacuum cleaner 23 is installed on the connecting plate ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com