Medical non-woven material free of bag breaking and high bacterium blocking performance and preparation method thereof

A non-woven material, melt-blown technology, applied in the field of medical and health fiber materials, can solve the problems of large longitudinal breaking strength, reduced antibacterial performance, affecting bursting strength, etc., to achieve high bursting strength, improve balance, and improve top breaking force effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

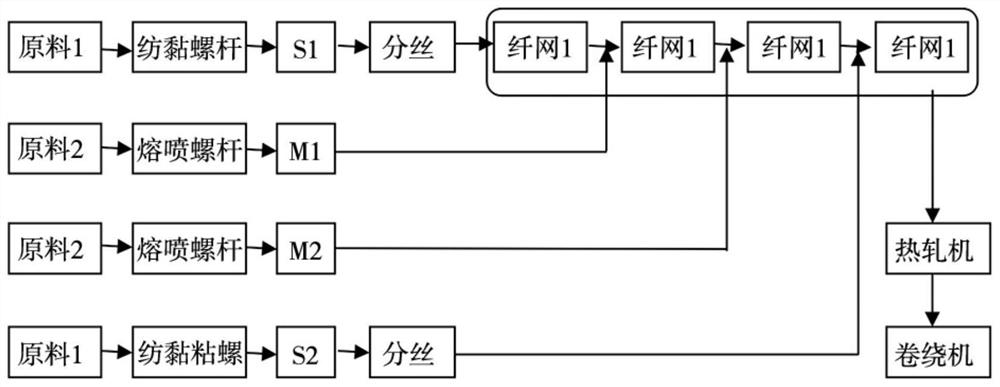

Method used

Image

Examples

Embodiment 1

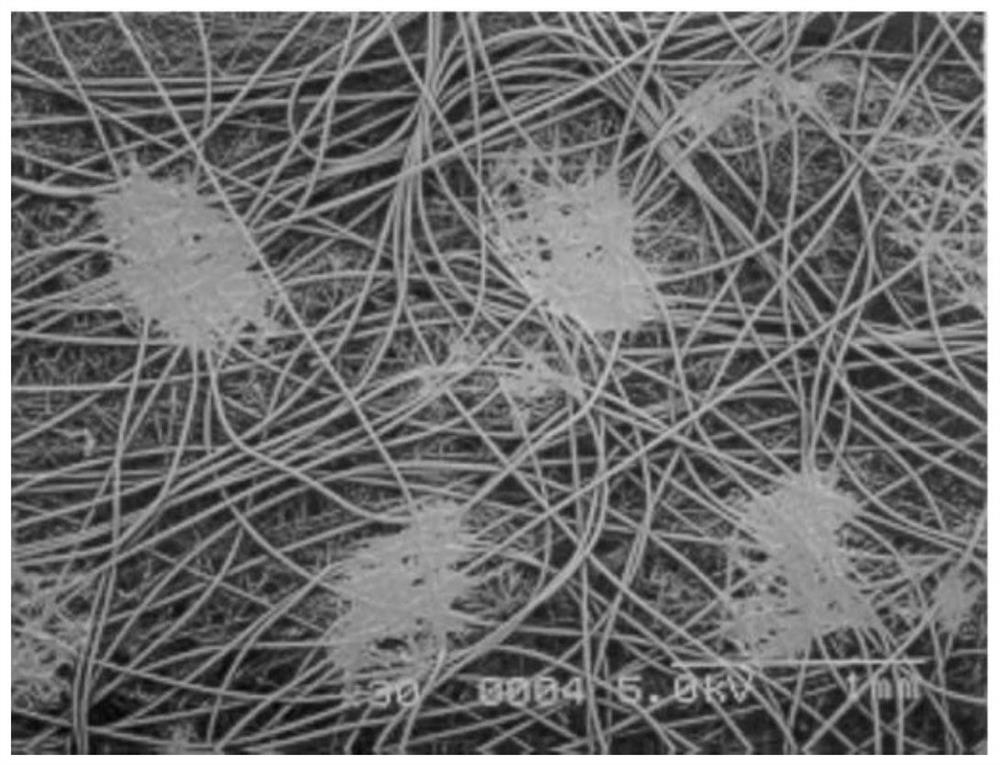

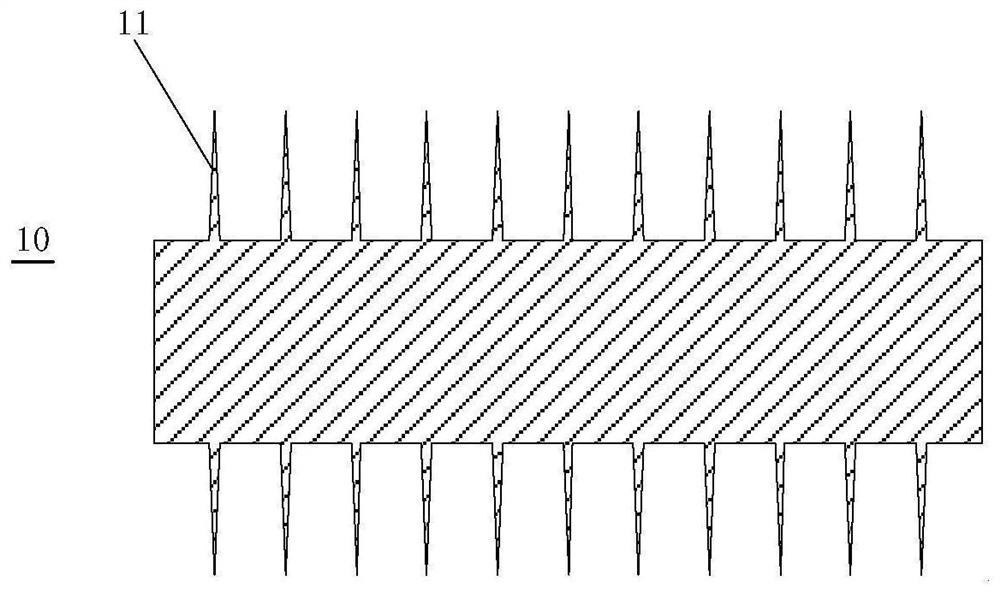

[0042] This embodiment provides a kind of melt-blown multi-pile fiber, such as image 3 As shown, the outer surface of the fiber trunk of the melt-blown multi-fluff fiber 10 is uniformly or non-uniformly grown with ultrafine fluff 11, and the material of the melt-blown multi-fluff fiber 10 includes polypropylene.

[0043] The above-mentioned melt-blown multi-fluff fiber has an ultra-fine fluff surface. When a plurality of melt-blown multi-fluff fibers are arranged, due to the winding bonding force between the ultra-fine fluff and the winding bonding force between the melt-blown multi-fluff fibers themselves, it is extremely The force of vertical and horizontal bonding between multiple melt-blown multi-fluff fibers is greatly improved, and due to the effect of ultra-fine fluff, the micropores between fibers are reduced and denser, which not only improves the uniformity of micropores, but also improves the Antibacterial properties.

[0044] Preferably, the average fiber finenes...

Embodiment 2

[0047] This embodiment provides a kind of melt-blown cloth, such as Figure 4 As shown, it includes a plurality of melt-blown multi-fluff fibers 10 that are intertwined with each other, and each of the melt-blown multi-fluff fibers 10 is preferably the melt-blown multi-fluff fiber in Example 1.

[0048]The above-mentioned melt-blown cloth forms intertwining between ultra-fine fluff and melt-blown multi-fluff fibers by intertwining and connecting a plurality of melt-blown multi-fluff fibers, which improves the vertical and horizontal bonding force between them, and improves This ensures the balance of the longitudinal and transverse fracture strength of the melt-blown cloth, thereby improving the bursting strength of the melt-blown cloth and making it difficult to break the bag. In addition, the micropore size between the fibers of the meltblown cloth is reduced, the density of the micropores is increased, and the uniformity of the micropores is improved, so that the meltblown ...

Embodiment 3

[0050] This embodiment provides a medical nonwoven material that does not break the package and has high antibacterial properties, including a first spunbonded cloth layer, a mixed cloth layer and a second spunbonded cloth layer connected in sequence;

[0051] The first spunbond layer includes at least one layer of first spunbond S1;

[0052] The mixed cloth layer is an arrangement and combination layer between the meltblown cloth M in at least one layer of embodiment 2 and the second spunbonded cloth S2 with a number of layers greater than or equal to 0;

[0053] The second spunbonded fabric layer includes at least one layer of third spunbonded fabric S3.

[0054] The above-mentioned medical non-woven material that does not break the package and has high resistance to bacteria is designed in layers, and a mixed cloth layer containing the melt-blown cloth of Example 2 is interposed between the upper and lower layers of spunbond cloth layers. In addition to the advantages of h...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com