Compound biodiesel pour point depressant, preparation method and application

A biodiesel and pour point depressant technology, which is applied in the petroleum industry, fuel additives, liquid carbon-containing fuels, etc., can solve the problems of poor fluidity of biodiesel pour point depressants, alleviate the shortage of petrochemical energy, change crystallization habits, and improve receptivity effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

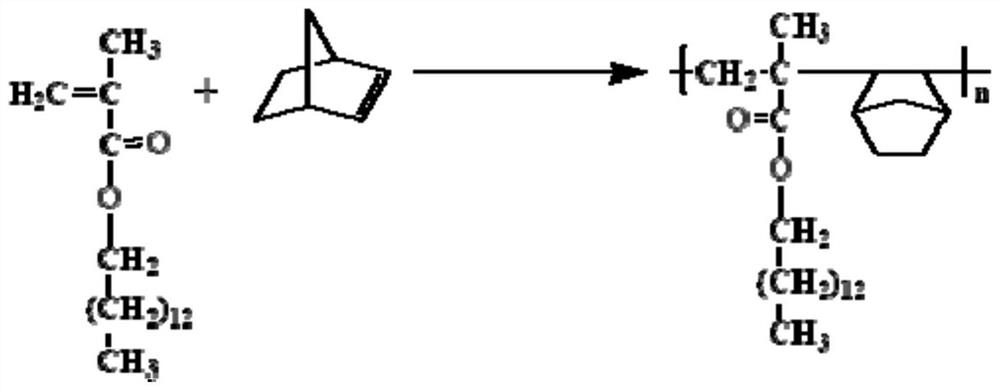

Method used

Image

Examples

Embodiment 1

[0030] Mix 3 parts of triethanolamine oleic acid soap with 3 parts of myristyl methacrylate-norbornene according to the ratio of 1:1 by weight to obtain a compound biodiesel pour point depressant.

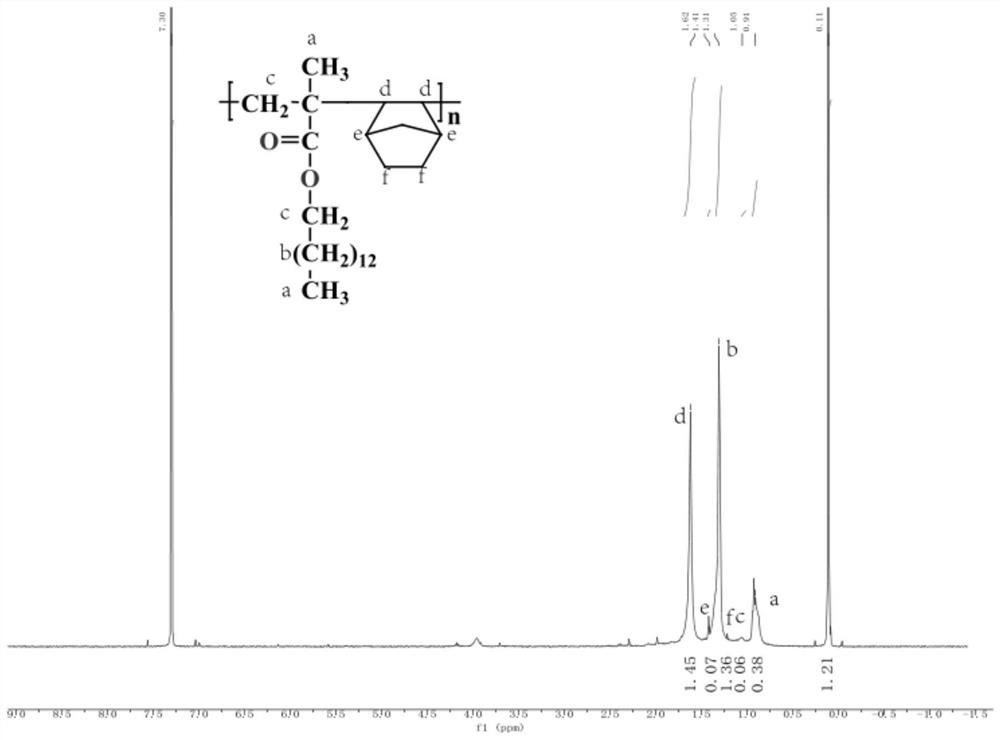

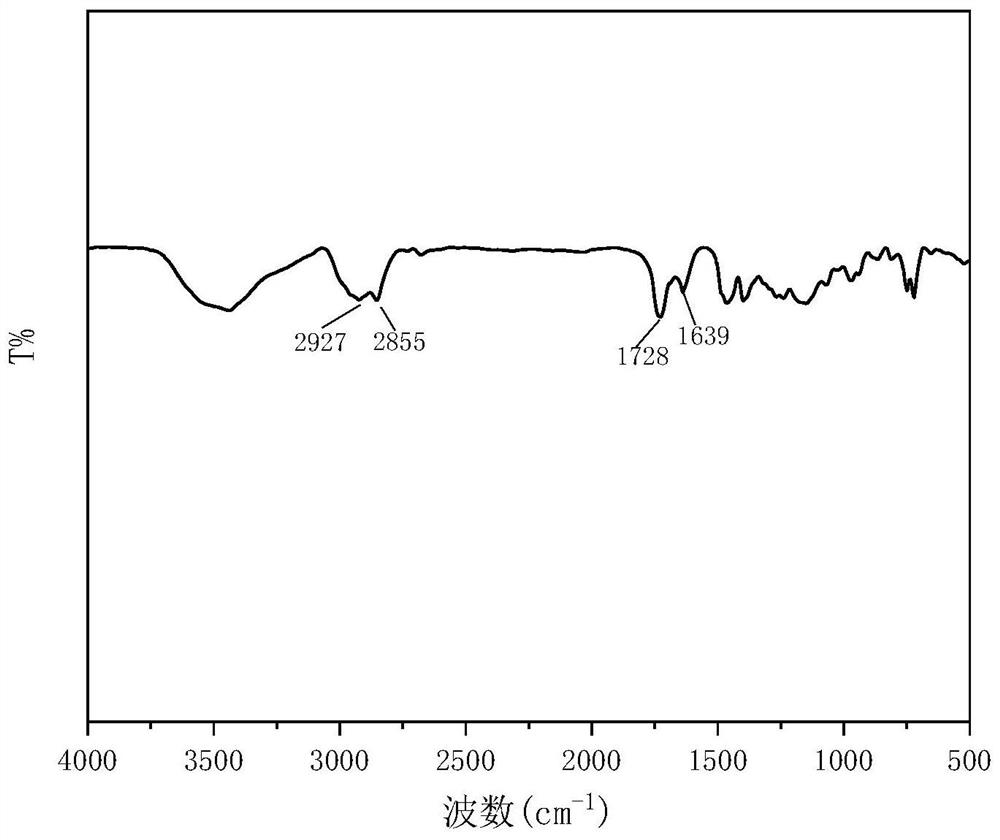

[0031] Such as figure 2 and image 3 shown by figure 2 It can be seen that c is -C=O-O-linked methylene-CH 2 The peak on -, d, e, f are norbornene-CH- peaks, δ H There is no obvious characteristic peak in 5-7, proves that C=C is fully aggregated; By image 3 It can be seen that 2927, 2855cm -1 The C-H characteristic absorption peaks in the norbornene structure appeared, 1728, 1639cm -1 It is the absorption peak of myristyl methacrylate C=O.

[0032] When the composite biodiesel pour point depressant is applied, it is added to soybean oil biodiesel at a mass percentage of 0.1-0.3%, and ultrasonically dispersed at 40° C. for 45 minutes. The test results are as follows:

[0033] The application effect of the composite biodiesel pour point depressant prepared in Table 1 Examp...

Embodiment 2

[0036] Mix 3 parts of glycerol random polyether with 3 parts of myristyl methacrylate-norbornene according to the ratio of 1:1 by weight to obtain a compound biodiesel pour point depressant.

[0037] When the composite biodiesel pour point depressant is applied, it is added to soybean oil biodiesel at a mass percentage of 0.1-0.3%, and ultrasonically dispersed at 40° C. for 45 minutes. The test results are as follows:

[0038] The application effect of the composite biodiesel pour point depressant prepared in Table 2 Example 2

[0039] Amount added CP / ℃ CFPP / ℃ PP / ℃ 0.1% 8 -2 -8 0.2% 7 -2 -10 0.3% 7 -3 -10

Embodiment 3

[0041] Mix 3 parts of fatty alcohol polyoxyethylene ether with 3 parts of myristyl methacrylate-norbornene according to the ratio of 1:1 by weight to obtain a compound biodiesel pour point depressant.

[0042] When the composite biodiesel pour point depressant is applied, it is added to soybean oil biodiesel at a mass percentage of 0.1-0.3%, and ultrasonically dispersed at 40° C. for 45 minutes. The test results are as follows:

[0043] The application effect of the composite biodiesel pour point depressant prepared in table 3 embodiment 3

[0044] Amount added CP / ℃ CFPP / ℃ PP / ℃ 0.1% 7 -2 -9 0.2% 6 -4 -10 0.3% 6 -5 -11

PUM

| Property | Measurement | Unit |

|---|---|---|

| cloud point | aaaaa | aaaaa |

| pour point | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com