HATN@graphene-containing anti-corrosion coating and preparation method thereof

A graphene and coating technology, which is applied in the field of HATN@graphene anti-corrosion coating and its preparation, can solve the problems of the decrease of electrochemical protection ability of anti-corrosion coating, reduce the conductivity of graphene, and fail to protect, etc., to achieve Continuous barrier range, improved dispersion, good electrochemical protection effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0039] Example 1: A HATN@graphene-containing anti-corrosion coating and its preparation method

[0040] The preparation method of the anti-corrosion coating containing HANT@graphene provided in this embodiment specifically includes the following steps:

[0041] Step 1, preparation of graphene oxide: at 0°C, slowly dissolve 2g of graphite and 1g of sodium nitrate in 46mL of concentrated sulfuric acid, slowly add 6g of potassium permanganate, and stir for 2 hours; Stir at 35°C for 2 hours, then raise the temperature to 95°C, slowly add 124mL of warm water and 30mL of 30% hydrogen peroxide to obtain a yellow solution without bubbles; use 5% hydrochloric acid and deionized water Repeated centrifugation and washing until the pH of the solution was neutral; finally dissolved in 100 mL of water, ultrasonicated for 3 hours, and freeze-dried to obtain graphene oxide powder.

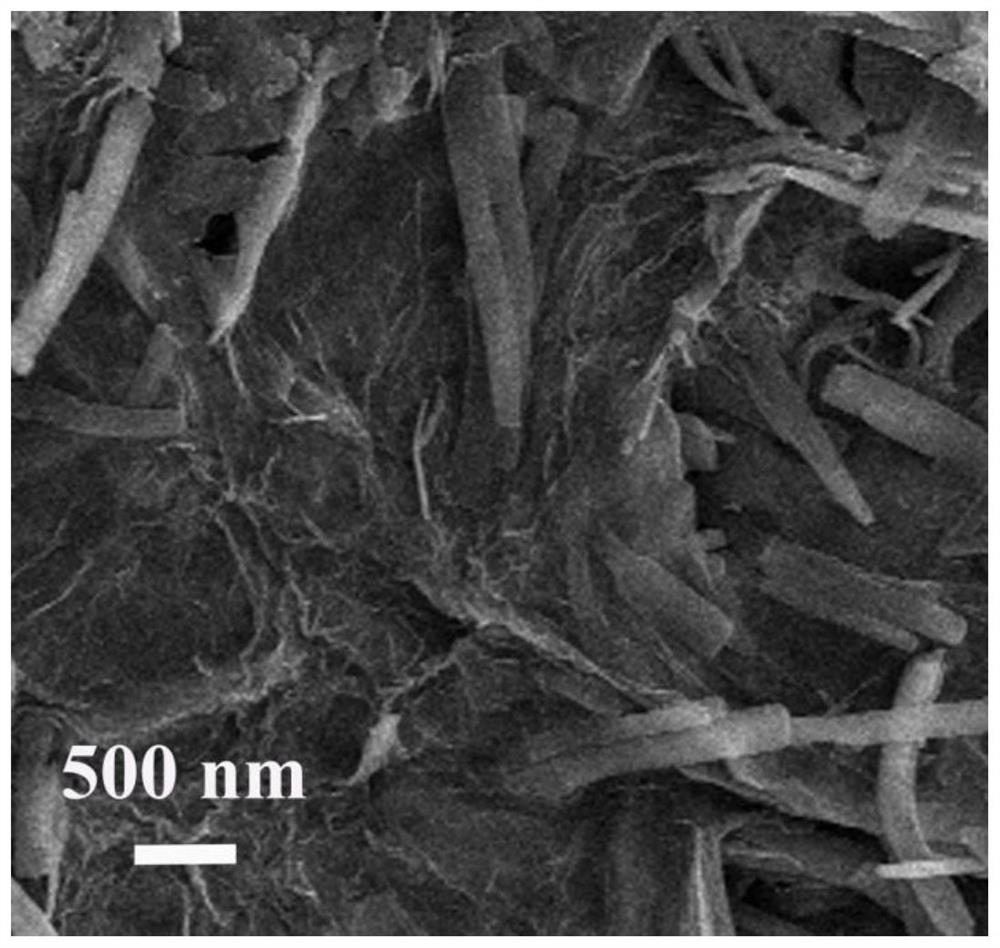

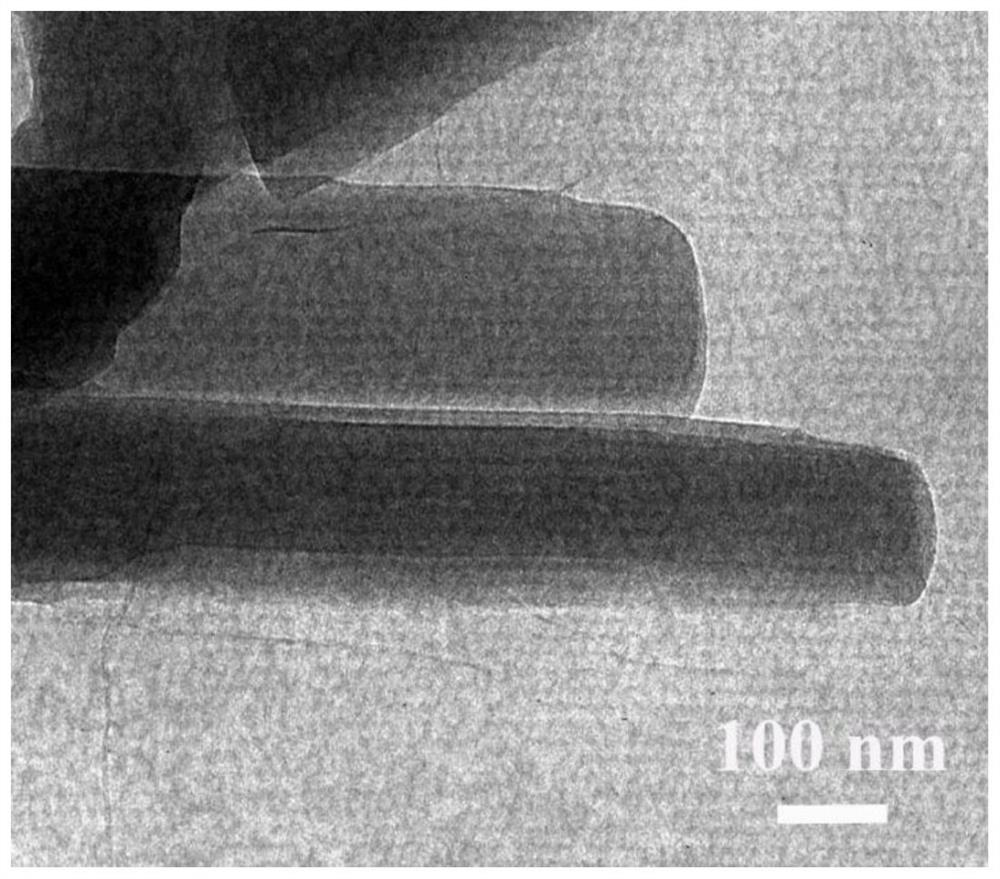

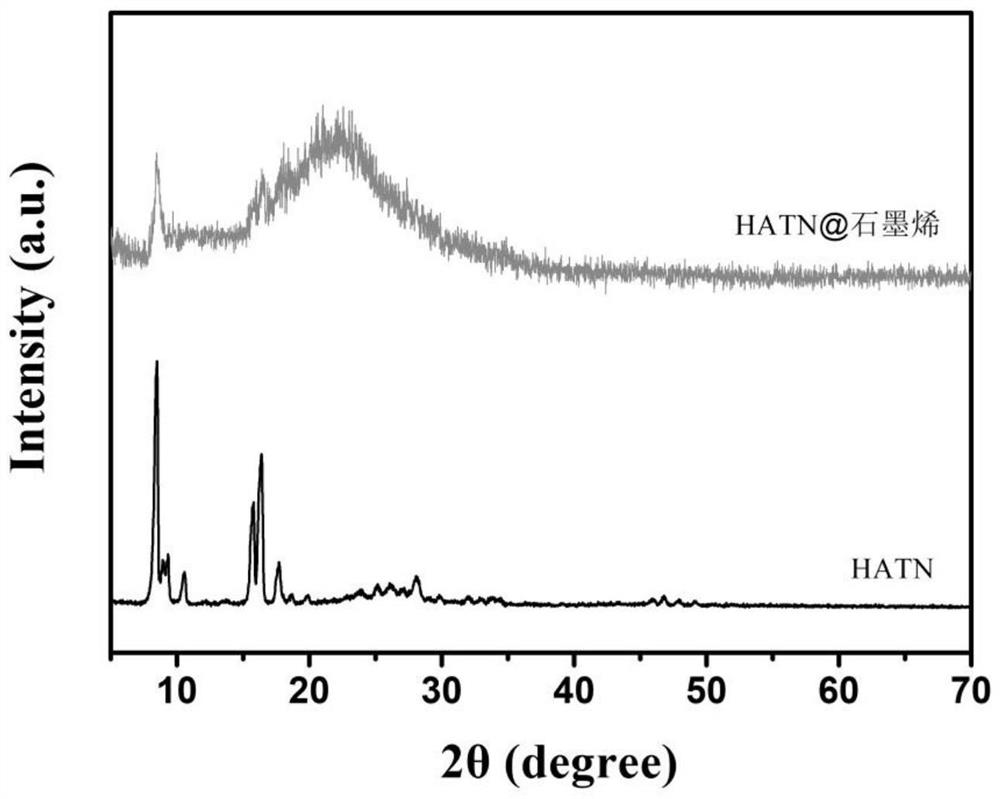

[0042] Step 2. Preparation of HATN@graphene composite material: Take 200mg of graphene oxide powder and dissol...

Embodiment 2

[0045] Embodiment 2: A kind of anticorrosion coating containing HATN@graphene and its preparation method

[0046] The preparation method of the anti-corrosion coating containing HANT@graphene provided in this embodiment specifically includes the following steps:

[0047] The preparation method of the present invention comprises the steps:

[0048] Step 1, preparation of graphene oxide: at 0°C, slowly dissolve 2g of graphite and 1g of sodium nitrate in 46mL of concentrated sulfuric acid, slowly add 6g of potassium permanganate, and stir for 2 hours; Stir at 35°C for 2 hours, then raise the temperature to 95°C, slowly add 124mL of warm water and 30mL of 30% hydrogen peroxide to obtain a yellow solution without bubbles; use 5% hydrochloric acid and deionized water Repeated centrifugation and washing until the pH of the solution was neutral; finally dissolved in 100 mL of water, ultrasonicated for 3 hours, and freeze-dried to obtain graphene oxide powder.

[0049] Step 2. Prepar...

Embodiment 3

[0051] Embodiment 3: A kind of anticorrosion coating containing HATN@graphene and its preparation method

[0052] The preparation method of the anti-corrosion coating containing HANT@graphene provided in this embodiment specifically includes the following steps:

[0053] The preparation method of the present invention comprises the steps:

[0054] Step 1, preparation of graphene oxide: at 0°C, slowly dissolve 2g of graphite and 1g of sodium nitrate in 46mL of concentrated sulfuric acid, slowly add 6g of potassium permanganate, and stir for 2 hours; Stir at 35°C for 2 hours, then raise the temperature to 95°C, slowly add 124mL of warm water and 30mL of 30% hydrogen peroxide to obtain a yellow solution without bubbles; use 5% hydrochloric acid and deionized water Repeated centrifugation and washing until the pH of the solution was neutral; finally dissolved in 100 mL of water, ultrasonicated for 3 hours, and freeze-dried to obtain graphene oxide powder.

[0055] Step 2. Prepar...

PUM

| Property | Measurement | Unit |

|---|---|---|

| thickness | aaaaa | aaaaa |

| thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com