Method for strengthening aerobic fermentation of kitchen waste by using oil-removing microbial preparation

A technology of food waste and aerobic fermentation, applied in the direction of microorganism-based methods, biochemical equipment and methods, microorganisms, etc., can solve the problems of large nitrogen loss, composting failure, and low-quality composting products, and achieve improved oil degradation efficiency, promote the production of organic acids, and improve the effect of recycling performance

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0039] One, the preparation of microbial bacterial agent:

[0040] (1) Inoculate Bacillus lysinus, Bacillus hiraeii, and Bacillus licheniformis into shake flasks containing 100 mL of culture medium at a volume ratio of 1%, and inoculate them at 35°C and shake flask rotation speed 160r / min. Cultivate for 24 hours; the medium is: peptone 10g, NaCl 10g, yeast extract 5g, distilled water 1000mL, pH 7.0-7.2.

[0041] (2) Mix the Bacillus lysinus solution, the Bacillus hirai bacteria solution, and the Bacillus licheniformis solution in a volume ratio of 1:1:1, and the cell concentrations of the three strains are 2.05, 3.22, and 1.73 g / L, to obtain the composite microbial bacterial agent.

[0042] 2. Determination of oil degradation rate of single bacteria and compound bacteria agent

[0043] Inoculate the cultured single bacteria or composite bacterial agents in a shaker flask containing 100mL oil medium at a volume ratio of 5%, culture at 35°C and a rotation speed of 160r / min for ...

Embodiment 2

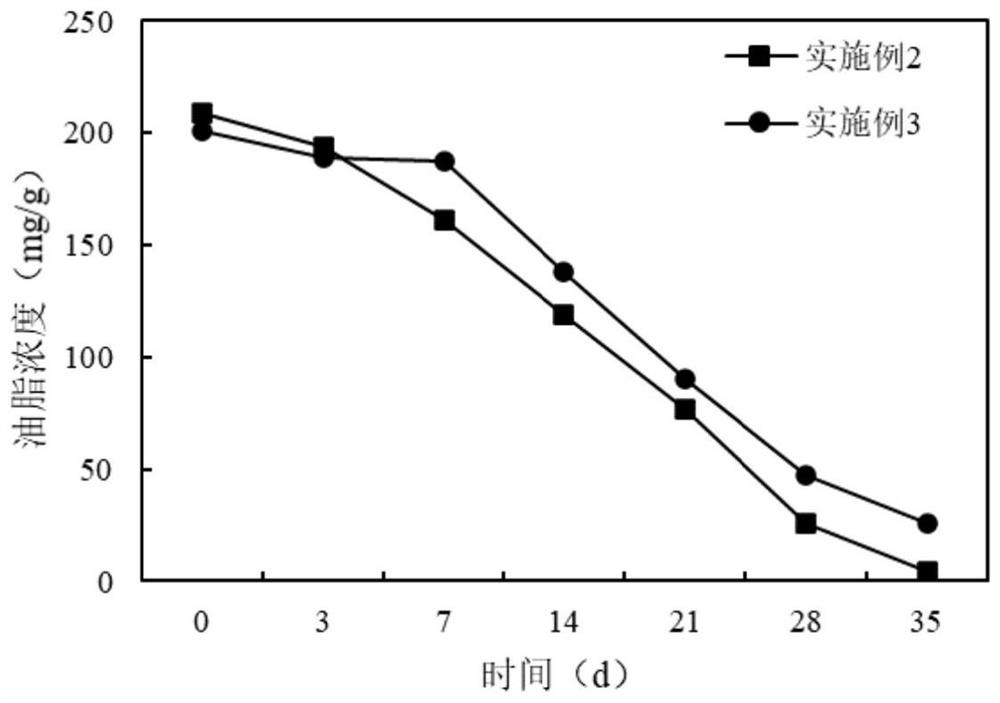

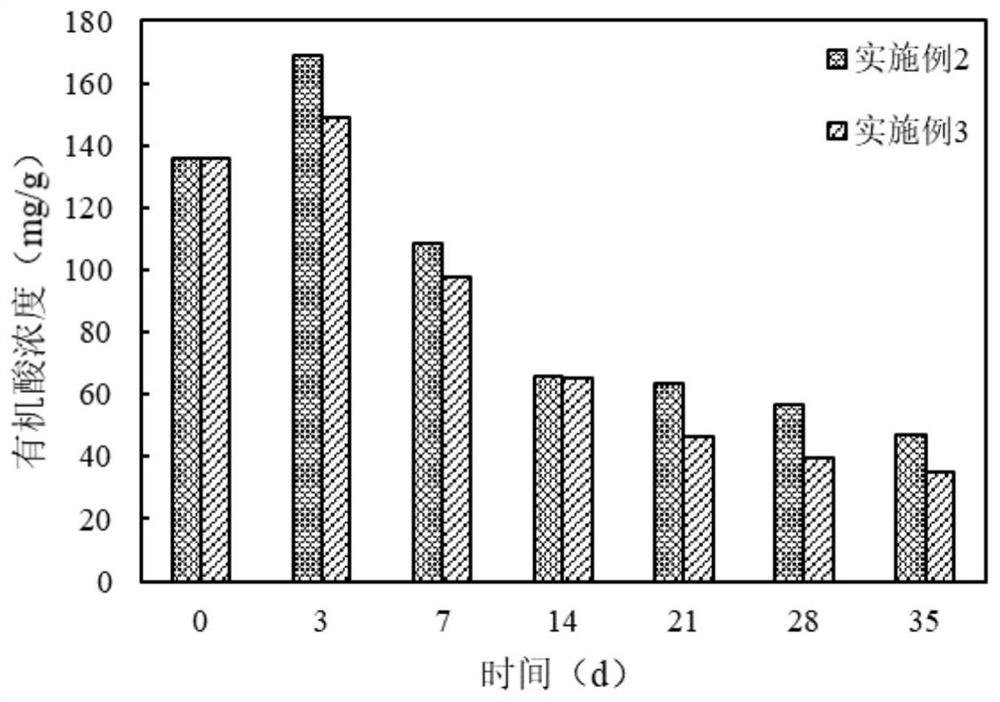

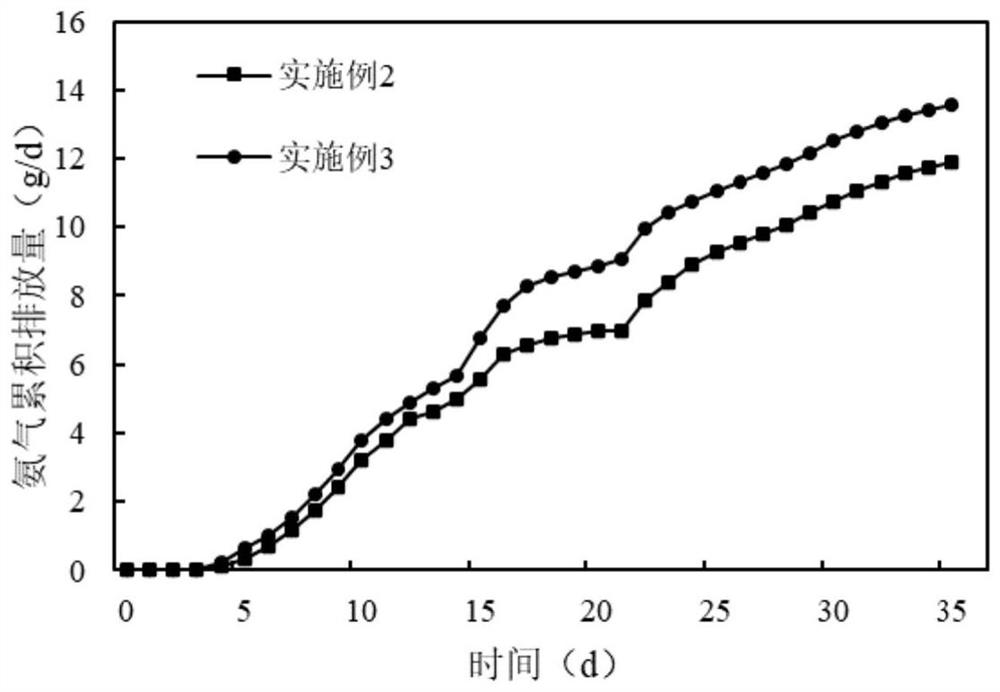

[0045] Embodiment 2: Utilize microorganism to promote the method for high-efficiency aerobic fermentation of kitchen waste

[0046] Proceed as follows:

[0047] (1) Filter and remove impurities from the food waste obtained on the same day, remove paper towels, plastics, bones, etc., and obtain 12 kg of food waste;

[0048] Table 1

[0049]

[0050] (2) Crushing the kitchen waste, the particle size is about 3-5mm, and the moisture is about 70-75%;

[0051] (3) Mix food waste with rice husk and / or straw (moisture content of rice husk or straw is 8%, rice straw, wheat straw, corn straw, rape straw, cotton straw) at a wet weight ratio of 8:2, The total weight is 15 kg, the control C / N is 25-30, the moisture content is about 60%, and it is stirred at room temperature for 30 minutes to make the materials evenly mixed;

[0052] (4) with 2×10 7 CFU / g inoculate the compound microbial agent into the compost mixture, and stir for 30 minutes to make the agent evenly mixed in the co...

Embodiment 3

[0055] Embodiment 3: the method for natural aerobic fermentation of kitchen waste

[0056] Proceed as follows,

[0057] (1) Filter and remove impurities from the food waste obtained on the same day, remove paper towels, plastics, bones, etc., and obtain 12 kg of food waste;

[0058] (2) Crushing the kitchen waste, the particle size is about 3-5mm, and the moisture is about 70-75%;

[0059] (3) Mix kitchen waste and straw with a wet weight ratio of 8:2, with a total weight of 15 kg, control C / N to 25-30, moisture content of about 60%, and stir at room temperature for 30 minutes;

[0060] (4) Put the compost mixture into the compost bucket, control the ventilation rate to 0.2L / (min·L pile body), measure the temperature of the pile body every day, and turn the pile manually on the 3rd, 7th, 14th, 21st, 28th, and 35th days , and take samples to determine relevant indicators, including oil concentration, organic acid concentration, cumulative ammonia discharge, nitrate nitrogen c...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com