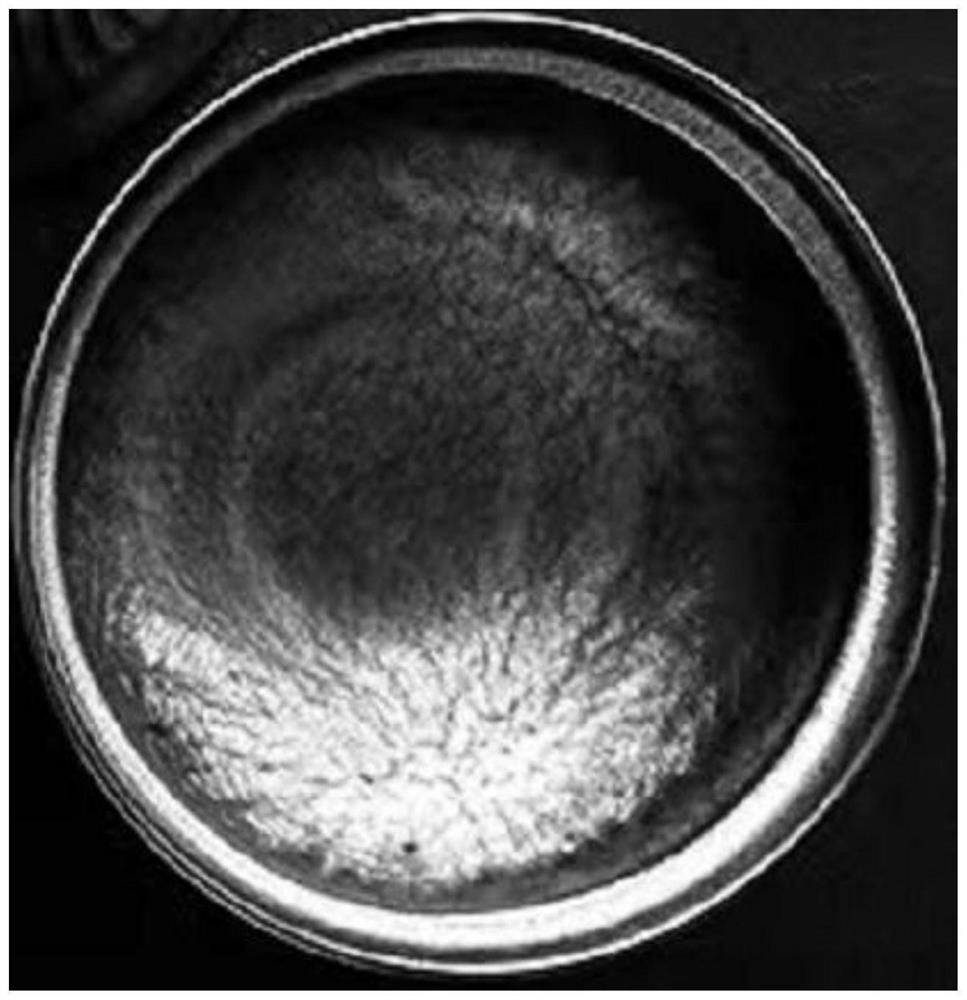

Transmutation glaze with metallic luster and transmutation glaze porcelain

A technology of metallic luster and kiln changing glaze, applied in the field of ceramics, can solve the problems of unnatural color base texture, difficult to improve production efficiency, complicated porcelain making process, etc., and achieve good antibacterial ability, poor thermal conductivity, and favorable grinding effect.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0037] In this example, a high-transparency basic glaze is prepared, and the specific implementation process is as follows:

[0038] Raw material preparation:

[0039] Albite feldspar 2.8kg, choose colorless and white albite;

[0040] Quartz 2.2kg, the quartz is low-temperature quartz, colorless and milky white;

[0041] Zircon 1kg, the choice of zircon is yellow and red;

[0042] Potassium feldspar 300g, the choice of potassium feldspar is flesh red;

[0043] Glass beads 800g;

[0044] The preparation steps are as follows:

[0045] Step J01: Take all raw materials other than glass microspheres and put them into a pulverizer to grind them until all the powders pass through a sieve with an aperture of 2mm. Use a mixer to mix the powders evenly again to obtain batch materials, and add the batch materials to the sintering process. In the furnace, heat up to 1380°C and keep it fired for 30 minutes, then add glass beads, use a ceramic stirring head to heat and mix for 15 minut...

Embodiment 2

[0049] In this example, a high-transparency basic glaze is prepared, and the specific implementation process is as follows:

[0050] Raw material preparation:

[0051] 3 kg of albite, the choice of albite is colorless and white;

[0052] Quartz 1.8kg, quartz is low-temperature quartz, the color is required to be colorless and milky white;

[0053] Zircon 1.2kg, the choice of zircon is yellow and red;

[0054] Potassium feldspar 500g, the choice of potassium feldspar is flesh red;

[0055] Glass beads 1kg;

[0056] The preparation steps are as follows:

[0057] Step J01: Take all raw materials other than glass microspheres and put them into a pulverizer to grind them until all the powders pass through a sieve with an aperture of 2mm. Use a mixer to mix the powders evenly again to obtain batch materials, and add the batch materials to the sintering process. In the furnace, heat up to 1400°C and keep it fired for 25 minutes, then add glass beads, use a ceramic stirring head to...

Embodiment 3

[0061] In this example, a high-transparency basic glaze is prepared, and the specific implementation process is as follows:

[0062] Raw material preparation:

[0063] 3.5kg of albite, the choice of albite is colorless and white;

[0064] Quartz 1.4kg, quartz is low-temperature quartz, and the color is required to be colorless and milky white;

[0065] Zircon 1.5kg, the choice of zircon is yellow and red;

[0066] Potassium feldspar 700g, the choice of potassium feldspar is flesh red;

[0067] Glass beads 1.2kg;

[0068] The preparation steps are as follows:

[0069] Step J01: Take all raw materials other than glass microspheres and put them into a pulverizer to grind them until all the powders pass through a sieve with an aperture of 2mm. Use a mixer to mix the powders evenly again to obtain batch materials, and add the batch materials to the sintering process. In the furnace, heat up to 1450°C and keep it fired for 20 minutes, then add glass beads, use a ceramic stirrin...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com