Punching device for production and processing of modular building connecting part and using method of punching device

A technology for punching devices and connectors, applied in positioning devices, metal processing equipment, metal processing machinery parts, etc., can solve the problems of lack of elastic limit, lack of automatic limit clamping of building connectors, etc.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

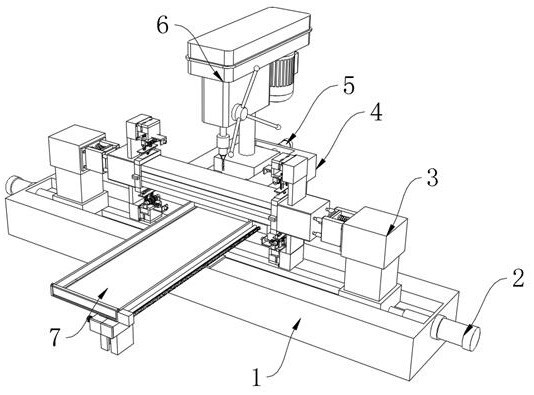

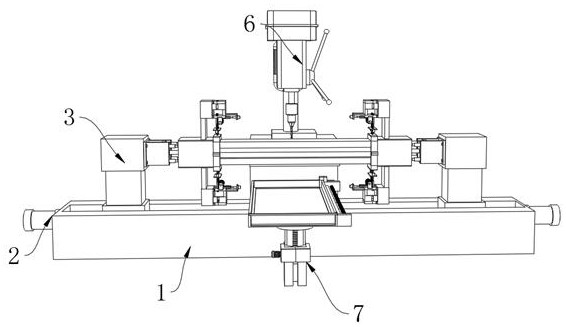

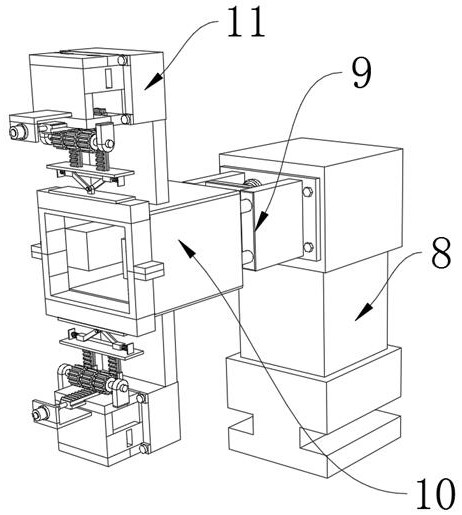

[0036] see Figure 1-8 , a drilling device for the production and processing of modular building connectors, comprising a carrying base 1, both sides of the carrying base 1 are fixedly connected with a first hydraulic piston cylinder 2 by screws, and the output end of the first hydraulic piston cylinder 2 The positioning structure 3 of the facing automated building parts is fixedly connected, and the positioning structure 3 of the facing automated building parts is slidingly connected with the inner side of the carrying base 1. One end of the carrying base 1 is fixedly connected with a longitudinal driving block 4, and one end of the longitudinal driving block 4 The second hydraulic piston cylinder 5 is fixedly connected by screws, and the output end of the second hydraulic piston cylinder 5 is fixedly connected with the drilling machine main body 6. The drilling machine main body 6 is slidingly connected with the inner side of the longitudinal drive block 4, and the base 1 is ...

Embodiment 2

[0050] A method of using a punching device for the production and processing of modular building connectors, which is applicable to the above-mentioned embodiments:

[0051] The first step: the first hydraulic piston cylinder 2 drives the positioning structure 3 of the opposing automated building parts to slide and displace to both sides, leaving a good clamping space between the positioning structures 3 of the opposing automated building parts;

[0052] The second step: place the processed connector between the mounting frame 10 on both sides, deduce and move the horizontal sliding guide block 8 through the first hydraulic piston cylinder 2 and reset to complete the lateral opposite clamping of the connection;

[0053] Step 3: complete automatic vertical clamping of the top and bottom ends of the processed connecting piece through the automatic opposite clamping clamp structure 11;

[0054] The fourth step: the sloshing force generated by the connecting piece during processin...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com