Steel bar cutting and packaging device for construction site

An on-site, steel bar technology, applied in the field of steel bar cutting and packing devices, can solve the problems of high labor intensity, inconvenient transportation, lack of steel bar auxiliary cutting, etc., and achieve the effect of improving efficiency and convenient transportation.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment

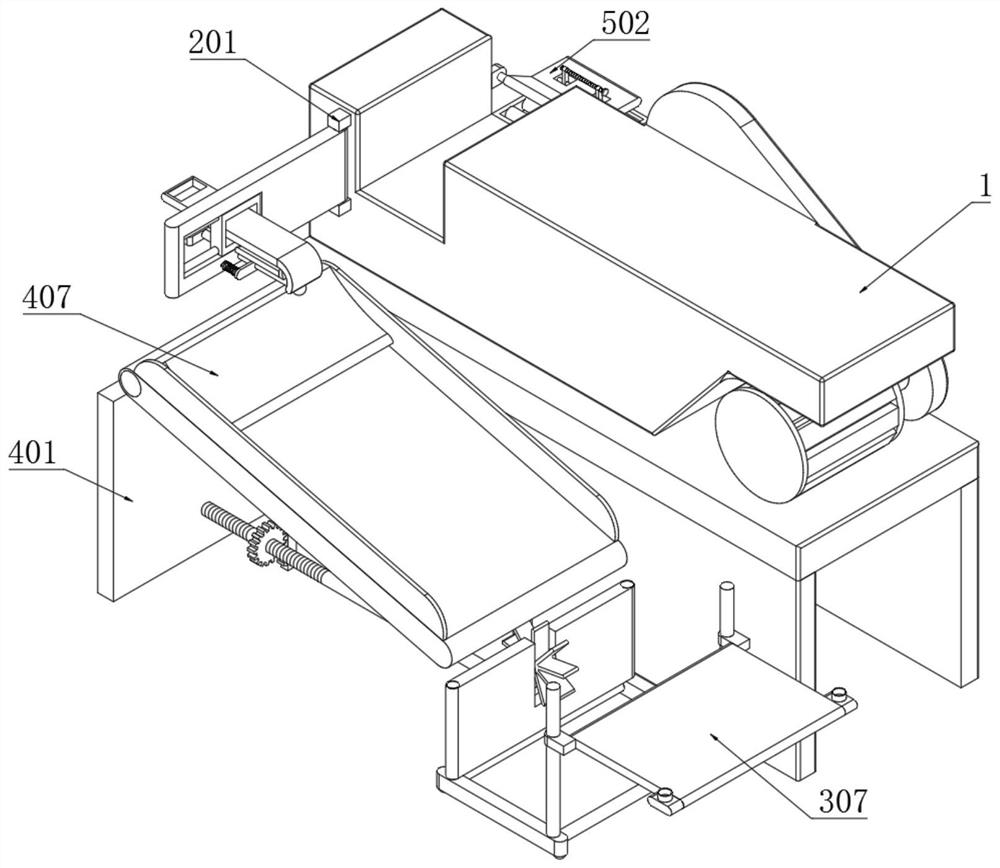

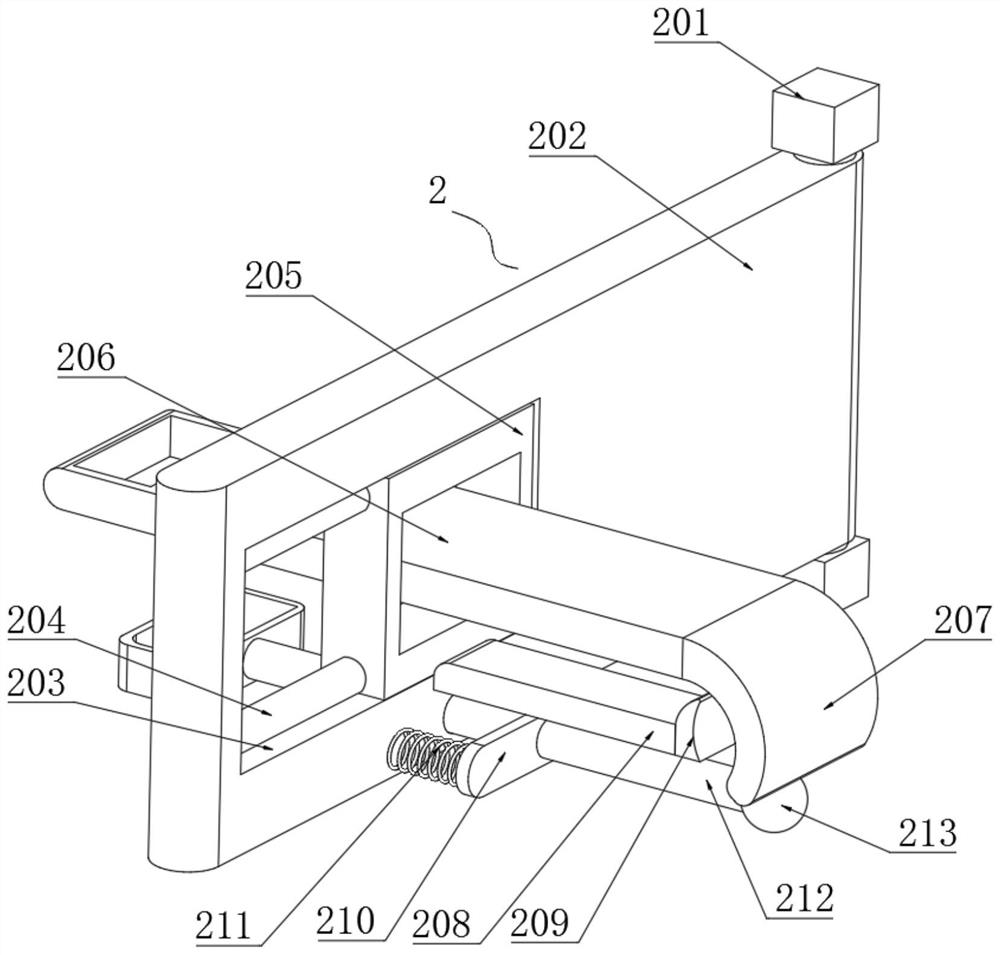

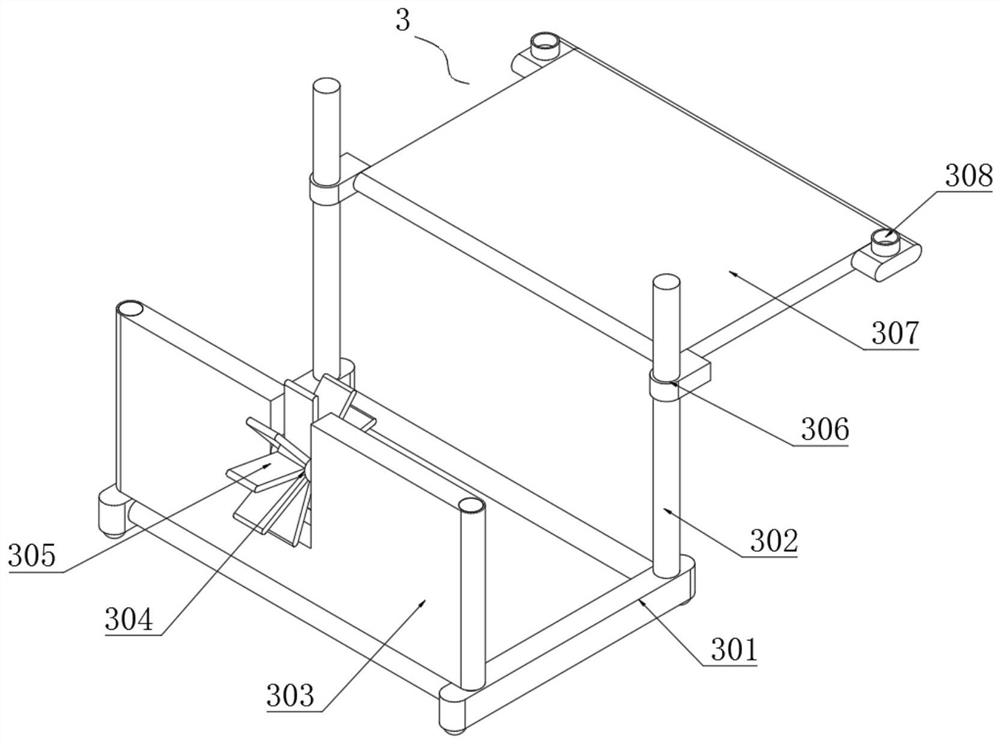

[0046] Example: such as Figure 1-8 As shown, the present invention provides a technical solution, a steel bar cutting and packaging device for construction sites, including a cutting machine body 1, an auxiliary mechanism 2 is installed at the bottom of one end of the cutting machine body 1, and the auxiliary mechanism 2 includes a fixed block 201, rotating plate 202, sliding hole 203, guide rod 204, sliding frame 205, connecting plate 206, limiting plate 207, support rod 208, limiting plate 209, vertical plate 210, contraction spring 211, slide bar 212 and rubber ball 213;

[0047] The bottom of one end of the cutting machine body 1 is symmetrically welded with a fixed block 201, the bottom of the fixed block 201 is rotated and embedded with a rotating plate 202, and one end of the rotating plate 202 is provided with a sliding hole 203, and the inner wall of the sliding hole 203 is symmetrically embedded with a guide rod 204, the outer end of the guide rod 204 is slidingly ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com