Continuous casting crystallizer casting powder for high-grade silicon steel as well as preparation method and application of continuous casting crystallizer casting powder

A continuous casting mold and mold slag technology, applied in the field of metallurgy, can solve the problem of inability to effectively suppress the dents and cracks on the surface of the billet, and reduce the incidence of dents and cracks on the surface of the billet, and the slag consumption increases and decreases. The effect of breakout risk

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

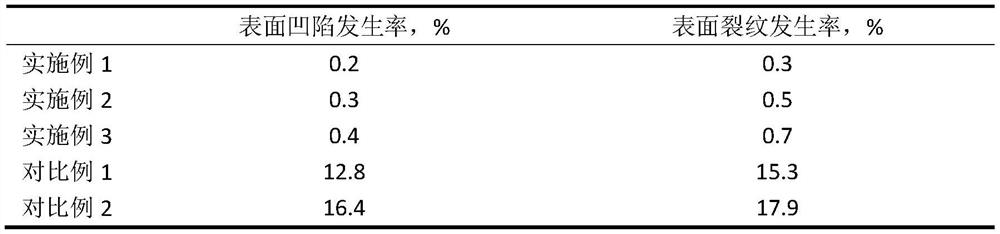

Examples

Embodiment 1

[0035] This embodiment provides a continuous casting mold powder for high-grade silicon steel, which is composed of the following chemical components in mass percentage: SiO 2 : 40%, CaO: 20%, MgO: 2.5%, Al 2 o 3 : 3%, Na 2 O: 16%, F: 13.0%, C: 3%, and the rest are unavoidable impurities;

[0036] The binary basicity of the mold flux CaO / SiO 2 0.5, the melting point is 950°C, and the viscosity at 1300°C is 0.25Pa·s.

[0037] The preparation method of described mold powder comprises the following steps:

[0038] S1: Weigh calcium silicate refining slag, calcium aluminate refining slag, limestone, bauxite, sodium fluoride, magnesia, quartz sand, fluorite according to the above formula ratio, put them into the mixer and mix them thoroughly. Obtain the mixture, then put the mixture into the melting furnace for pre-melting, the pre-melting temperature is 1450°C, and the holding time is 1.0h, to obtain the pre-melted mixture;

[0039] S2: Cool down the pre-melted mixture to ro...

Embodiment 2

[0043] This embodiment provides a continuous casting mold powder for high-grade silicon steel, which is composed of the following chemical components in mass percentage: SiO 2 : 42%, CaO: 23%, MgO: 1.8%, Al 2 o 3 : 2%, Na 2 O: 14%, F: 12.0%, C: 2%, and the rest are unavoidable impurities;

[0044] The binary basicity of the mold flux CaO / SiO 2 It is 0.55, the melting point is 970°C, and the viscosity at 1300°C is 0.3Pa·s.

[0045] The preparation method of described mold powder comprises the following steps:

[0046] S1: Weigh calcium silicate refining slag, calcium aluminate refining slag, limestone, bauxite, sodium fluoride, magnesia, quartz sand, fluorite according to the above formula ratio, put them into the mixer and mix them thoroughly. Obtain the mixture, then put the mixture into the melting furnace for pre-melting, the pre-melting temperature is 1500°C, and the holding time is 1.5h, to obtain the pre-melted mixture;

[0047] S2: Cool down the pre-melted mixture...

Embodiment 3

[0051] This embodiment provides a continuous casting mold powder for high-grade silicon steel, which is composed of the following chemical components in mass percentage: SiO 2 : 45%, CaO: 27%, MgO: 1.0%, Al 2 o 3 : 1%, Na 2 O: 12%, F: 11.0%, C: 1%, and the rest are unavoidable impurities;

[0052] The binary basicity of the mold flux CaO / SiO 2 It is 0.60, the melting point is 1000°C, and the viscosity at 1300°C is 0.35Pa·s.

[0053] The preparation method of described mold powder comprises the following steps:

[0054] S1: Weigh calcium silicate refining slag, calcium aluminate refining slag, limestone, bauxite, sodium fluoride, magnesia, quartz sand, fluorite according to the above formula ratio, put them into the mixer and mix them thoroughly. Obtain the mixture, and then put the mixture into the melting furnace for pre-melting, the pre-melting temperature is 1500°C, and the holding time is 2.0h, to obtain the pre-melted mixture;

[0055] S2: Cool down the pre-melted m...

PUM

| Property | Measurement | Unit |

|---|---|---|

| particle size | aaaaa | aaaaa |

| melting point | aaaaa | aaaaa |

| melting point | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com