Boiler waste heat, waste steam and waste water recovery system

A boiler waste heat and waste water recovery technology, applied in boiler cleaning devices, heat exchangers, indirect heat exchangers, etc., can solve problems such as environmental pollution, waste of water resources, heat energy loss, etc., and achieve the goal of avoiding environmental pollution and saving costs Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0020] The specific implementation manners of the present invention will be further described in detail below in conjunction with the accompanying drawings and embodiments. The following examples are used to illustrate the present invention, but are not intended to limit the scope of the present invention.

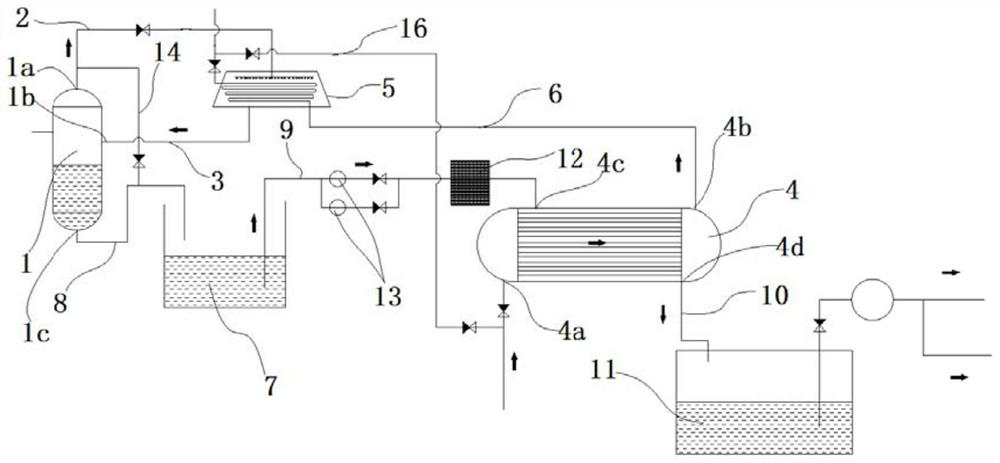

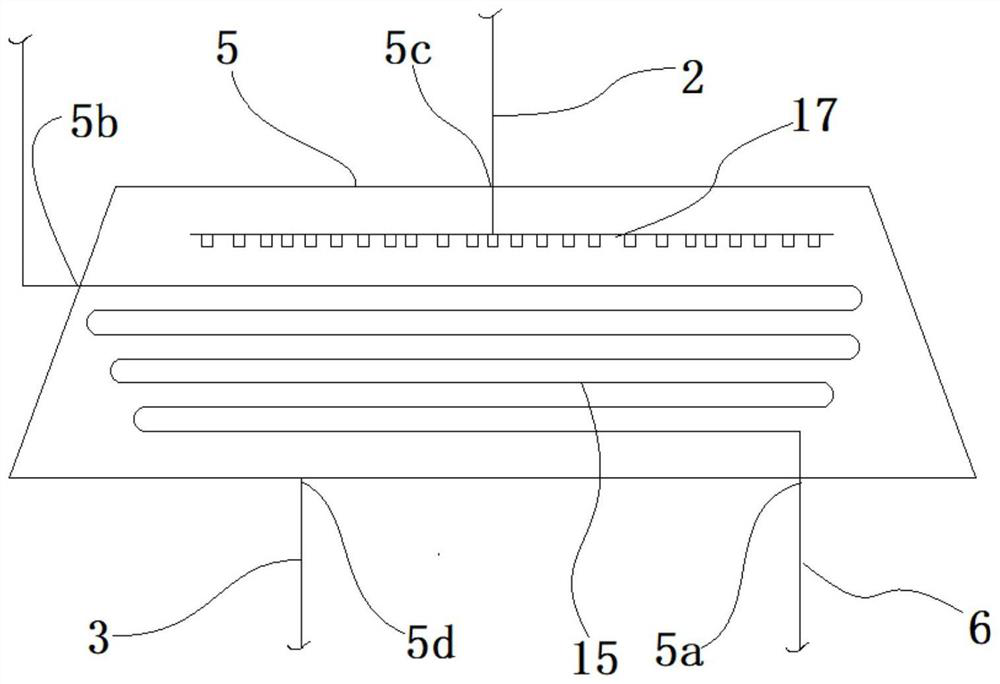

[0021] Such as figure 1 and figure 2 As shown, a boiler waste heat, waste steam and waste water recovery system of a preferred embodiment of the embodiment of the present invention;

[0022] Among them, the steam recovery system includes a fixed discharge expansion vessel 1, a second heat exchanger 5, a cooling water pipe 6, a exhaust steam pipe 2 and a return water pipe 3; the fixed discharge expansion vessel 1 is provided with an exhaust port 1a and a return water inlet 1b , the drain port 1c and the interface (not shown in the figure) used to connect with the boiler. The exhaust port 1a at the upper end of the fixed row expansion vessel 1, the other end of the exhau...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com