Central control type seabed multi-head continuous sampling drilling machine

A sampling drilling rig, multi-head technology, applied in rotary drilling rigs, rotary drilling, impact drilling and other directions, can solve problems such as low sampling efficiency, and achieve the effect of improving efficiency, compact structure and small core disturbance

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0065] The wireline coring method in the prior art is that during the drilling process, when the core is filled with the core tube, there is no need to lift the drill pipe out of the hole, but the inner hole of the drill pipe is used as a channel, with the help of rope and special fishing tools A core drilling method that lifts the core stored in the core tube inside the drill pipe to the hole position during the drilling process. Since there is no need to lift the drill pipe out of the hole, the tripping time of the drilling tool is greatly reduced. The core tube is used as the inner tube in the drill pipe, and the core tube is pulled out from the drill pipe when the core is filled with the core tube.

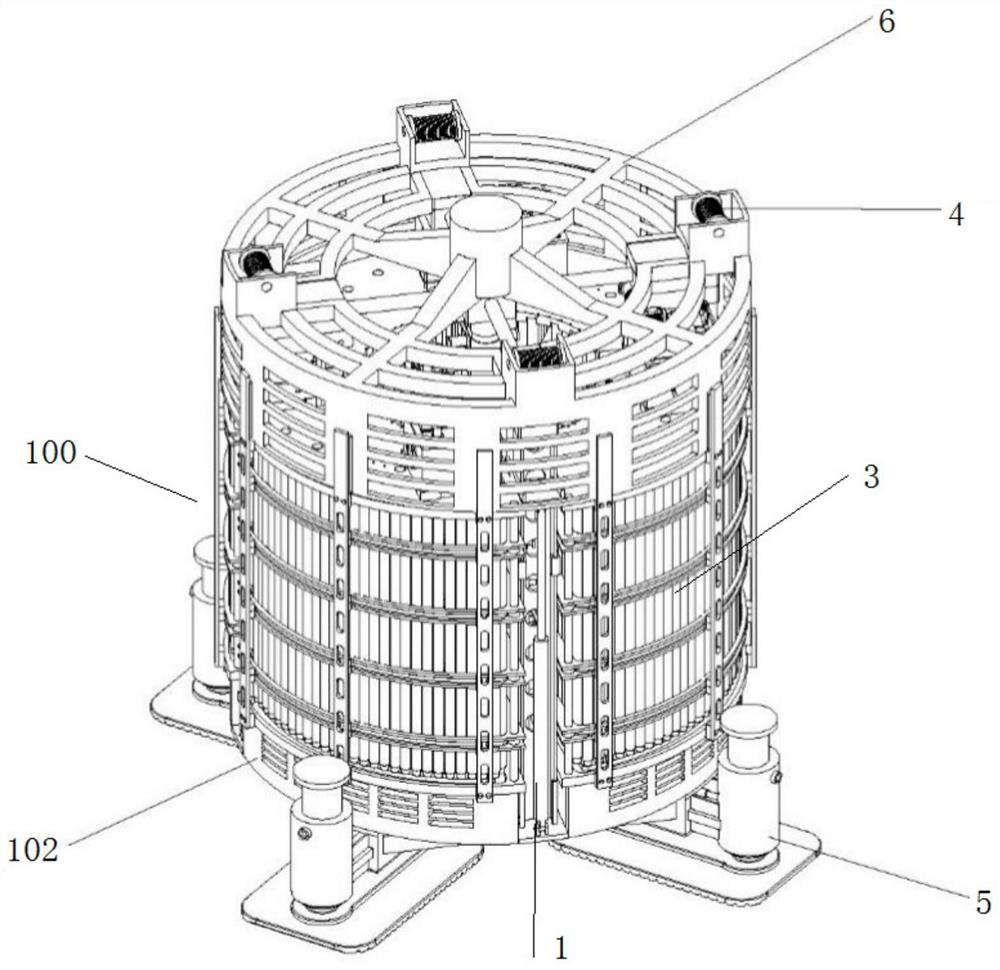

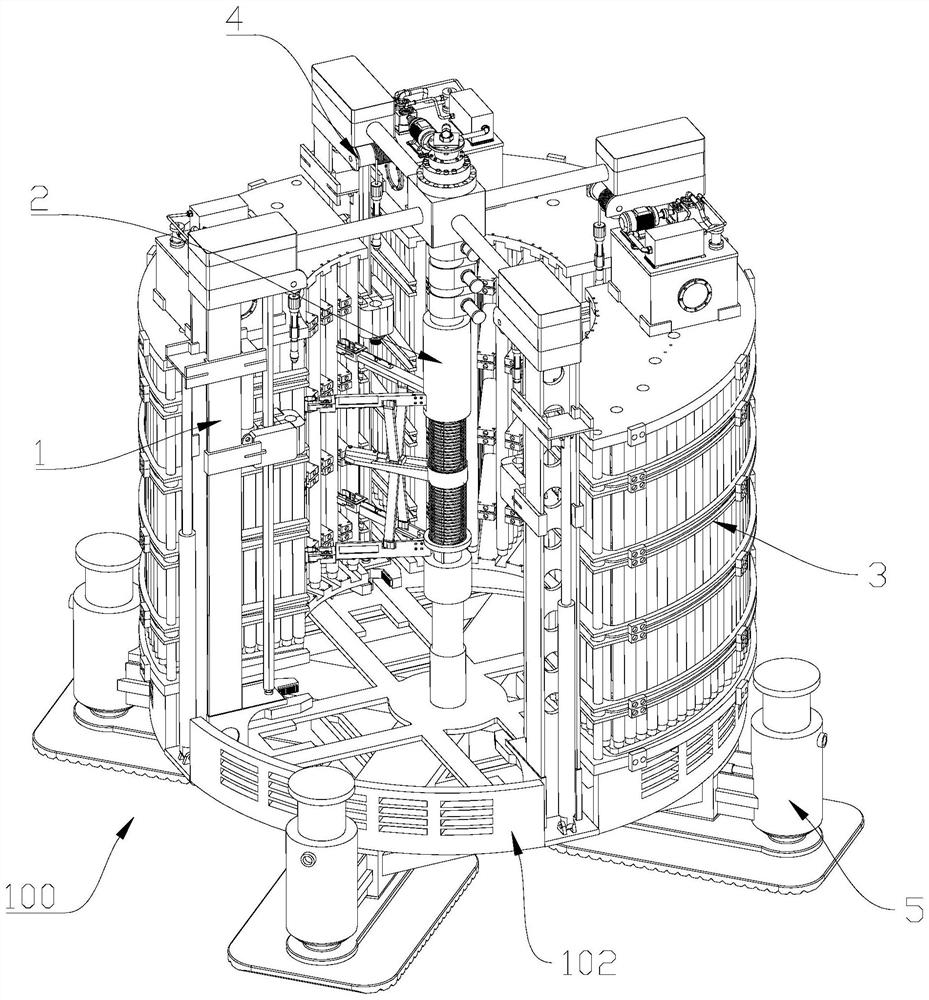

[0066] Such as Figure 1-Figure 16 As shown, the present embodiment provides a centrally controlled subsea multi-head continuous sampling drilling rig, including a drilling rig 100 with a drilling tool moving mechanism 2 and a power drilling mechanism 1 for driving a drill pi...

specific Embodiment approach

[0071] see figure 2 and image 3 As shown, the drilling tool storage mechanism of this embodiment includes four, and the four drilling tool storage mechanisms are arranged at intervals and arranged around the central drilling tool moving mechanism 2, so that the drilling tool moving mechanism 2 rotates at 360° The drill pipe 200 and the core pipe 300 in different positions in the four drilling tool storage mechanisms can be grasped at the same time, the structure is compact, and the internal space of the drilling machine is fully utilized.

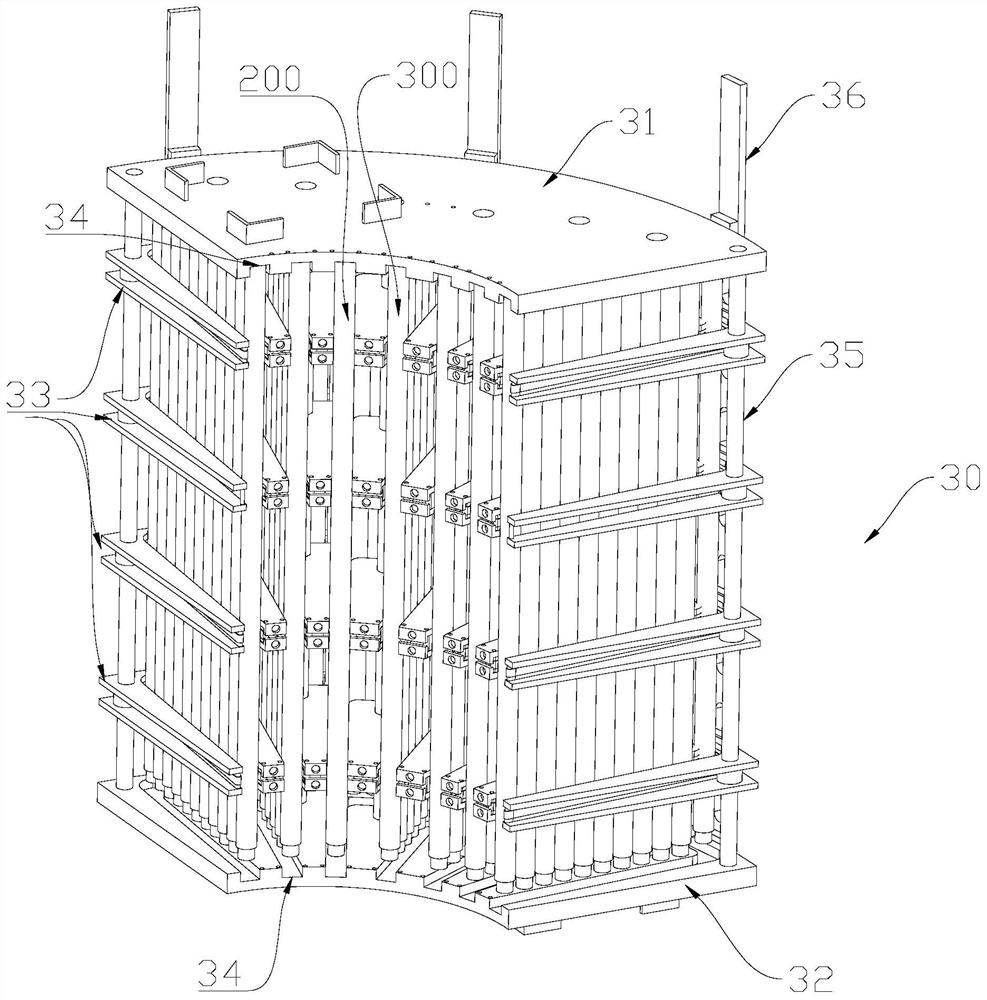

[0072] Specifically, the drilling tool storage mechanism of the present embodiment includes a drilling library 30, see image 3 and Figure 4 As shown, the radial section of the drill storehouse 30 is fan-shaped, and the center of the fan-ring is located on the central axis of the drilling machine 100. The drill storehouse 30 includes a connected upper plate 31, a chassis 32 and two or more transmission plates 33, wherein: see figure...

Embodiment 2

[0081] This embodiment is an improvement made on the basis of the above-mentioned embodiments. In this embodiment, a specific implementation of the drilling tool moving mechanism 2 is provided. See figure 2 and Figure 6 , Figure 7 As shown, the drilling tool moving mechanism 2 of this embodiment includes a central column 20, a driving device 21 located on the central column 20, an upper rotating cylinder 22, a lower rotating cylinder 23 and a gripper assembly 24, wherein: the gripper assembly 24 The upper and lower ends of the upper and lower ends are respectively connected with an upper rotating cylinder 22 and a lower rotating cylinder 23, and the lower rotating cylinder 23 is sleeved on the lower end of the upper rotating cylinder 22, such as Figure 7 As shown, the driving end of the driving device 21 is connected to the upper rotating cylinder 23, and is used to drive the handle assembly 24 to rotate 360° with the center column 20 as the axis; the handle assembly 24 i...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com