Preparation method of high-bearing low-temperature insensitive slow-rebound sponge

A slow-rebound sponge and high-load-bearing technology, which is applied in the field of preparation of high-load-bearing low-temperature insensitive slow-rebound sponge, can solve the problems of hard hand feeling and poor load-bearing performance of the sponge, and achieve soft hand feeling, excellent bearing capacity and reduced cost Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

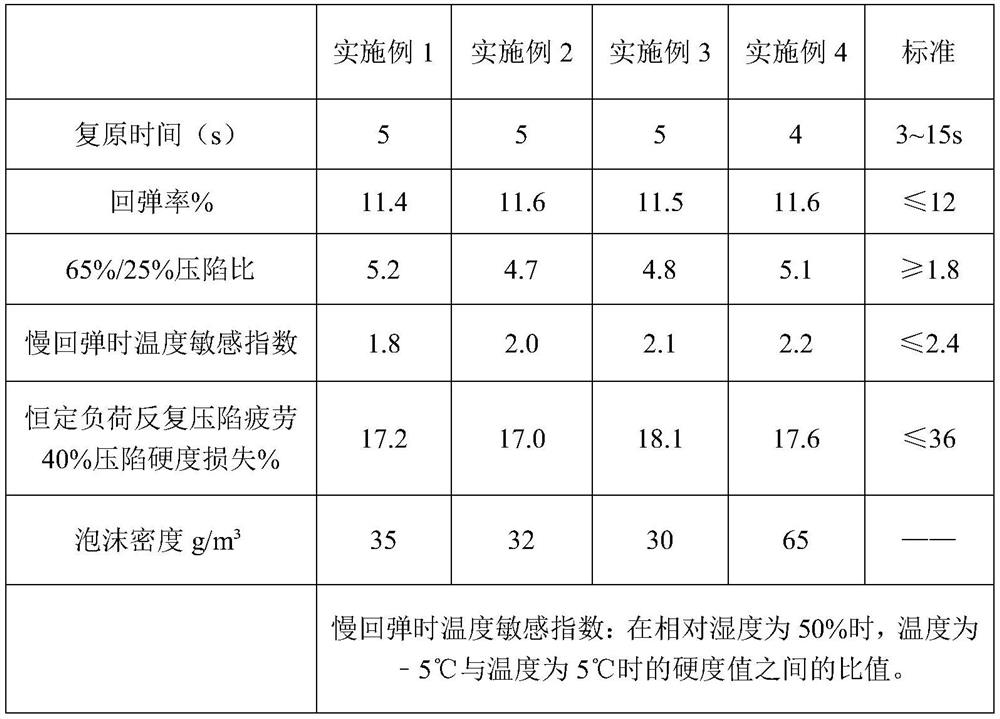

Examples

Embodiment 1

[0017] Polyether polyol A: polyether polyol ZS-350G (purchased from Jiangsu Zhongshan New Material Co., Ltd.), polyoxypropylene oxide polyether triol, hydroxyl value: 30 (mgKOH / g), f( functionality)=3. Polyether polyol B: polyether polyol ZS-3160 (purchased from Jiangsu Zhongshan New Material Co., Ltd.), polyoxypropylene oxide polyether triol, hydroxyl value: 160 (mgKOH / g), f( functionality)=3. Polyether polyol C: polyether polyol C is ZS-8180 (purchased from Jiangsu Zhongshan New Material Co., Ltd.), polyoxypropylene oxide polyether tetraol, hydroxyl value: 180 (mgKOH / g), f = 4 (functionality). Polymer polyol D: Polymer polyol POP-720 (purchased from Jiangsu Zhongshan New Material Co., Ltd.), polyoxypropylene oxide polymer trihydric alcohol, hydroxyl value: 190 (mgKOH / g), solid content is 20%, f=3 (functionality).

[0018] A33 (commercially available) is a 33% triethylenediamine solution and is a tertiary amine catalyst. T12 (commercially available) is dibutyltin dilaura...

Embodiment 2

[0022] Add 45g polyether polyol A, 10g polyether polyol B, 40g polyether polyol C and 5g polyether polyol D into a 1L beaker, then add A33 (tertiary amine catalyst) 0.4g, T12 (organometallic Catalyst) 0.15g, LR-1085 (organic silicone oil) 0.35g and deionized water 3.5g, stirred for 30s and mixed evenly to obtain white material. Wherein polyether polyol A, polyether polyol B, polyether polyol C and polyether polyol D are the same as in Example 1.

[0023] Free foaming: Pour 40g of TDI (toluene diisocyanate) into the mixed white material, stir for 10 seconds under the mixer at a speed of 4000-5000r / min, pour the foamed liquid into the mold and fully foam until completely After aging (it takes 24 hours from foaming to full aging), it is cut to obtain a high-load low-temperature insensitive slow-rebound sponge. The rebound time of this high-load low-temperature insensitive slow-rebound sponge is about 5s, and it does not feel hard at a low temperature of -10°C to 10°C, that is, i...

Embodiment 3

[0025] Add 40g polyether polyol A, 10g polyether polyol B, 40g polyether polyol C and 10g polymer polyol D into a 1L beaker, then add A33 (tertiary amine catalyst) 0.3g, T12 (organometallic Catalyst) 0.1g, LR-1085 (organic silicone oil) 0.5g, deionized water 4g, stir for 30s and mix evenly to get white material. Wherein polyether polyol A, polyether polyol B, polyether polyol C and polyether polyol D are the same as in Example 1.

[0026] Free foaming: Pour 45g of TDI (toluene diisocyanate) into the mixed white material, stir for 10 seconds under the mixer at a speed of 4000-5000r / min, pour the foamed liquid into the mold and fully foam until completely After aging (it takes 24 hours from foaming to full aging), it is cut to obtain a high-load low-temperature insensitive slow-rebound sponge. The rebound time of this high-load low-temperature insensitive slow-rebound sponge is about 5s, and it does not feel hard at a low temperature of -10°C to 10°C, that is, it is not sensiti...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Density | aaaaa | aaaaa |

| Density | aaaaa | aaaaa |

| Density | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - Generate Ideas

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com