Single point mooring yoke support hinged joint structure with offshore bearing replacing function

A single-point system and mooring yoke technology, which is applied to the rigid support of bearing components, bearings, bearing unloading, etc., can solve the problems such as the difficulty of replacing the roll bearing of the yoke hinge joint, and achieve the solution of difficult replacement and strong bearing capacity , easy maintenance effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0027] The present invention will be further described in detail below in conjunction with the accompanying drawings and specific embodiments.

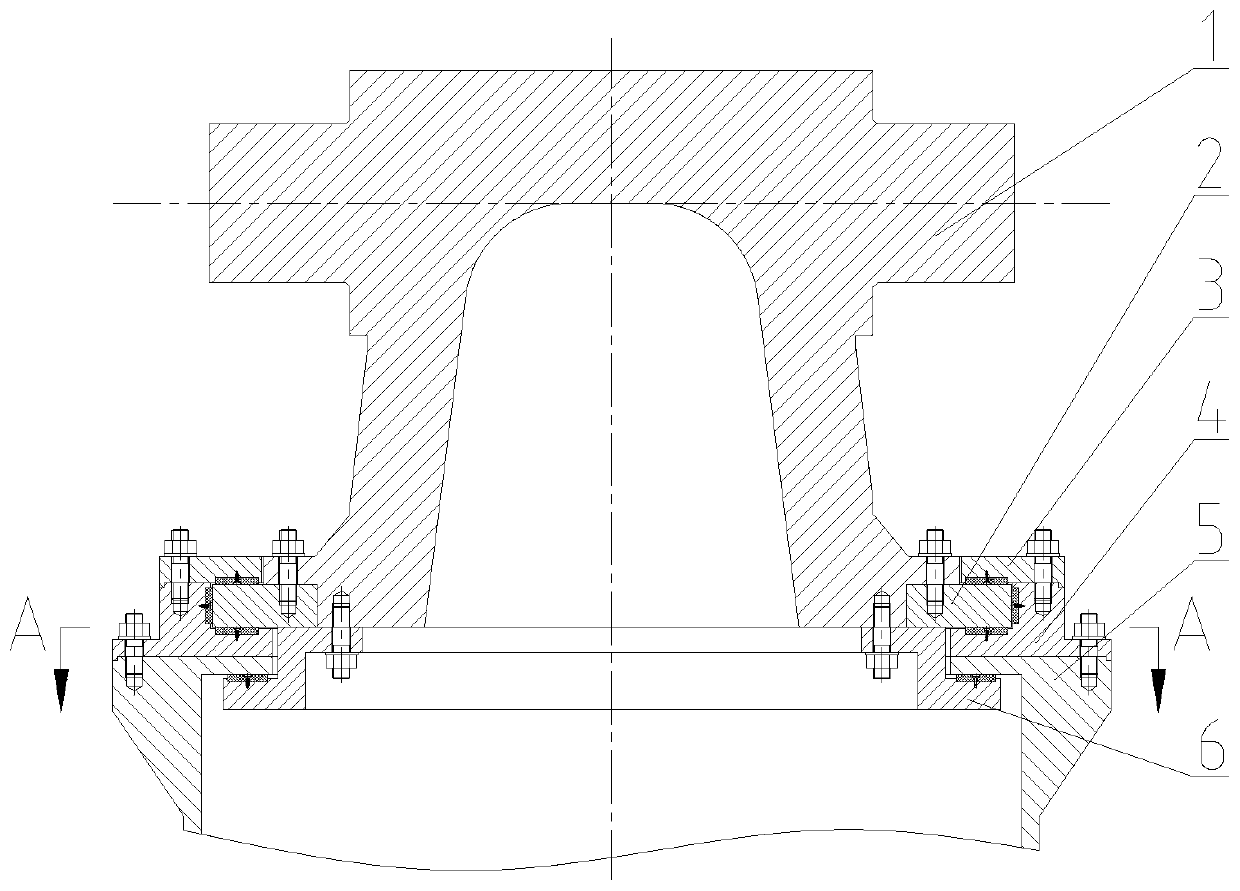

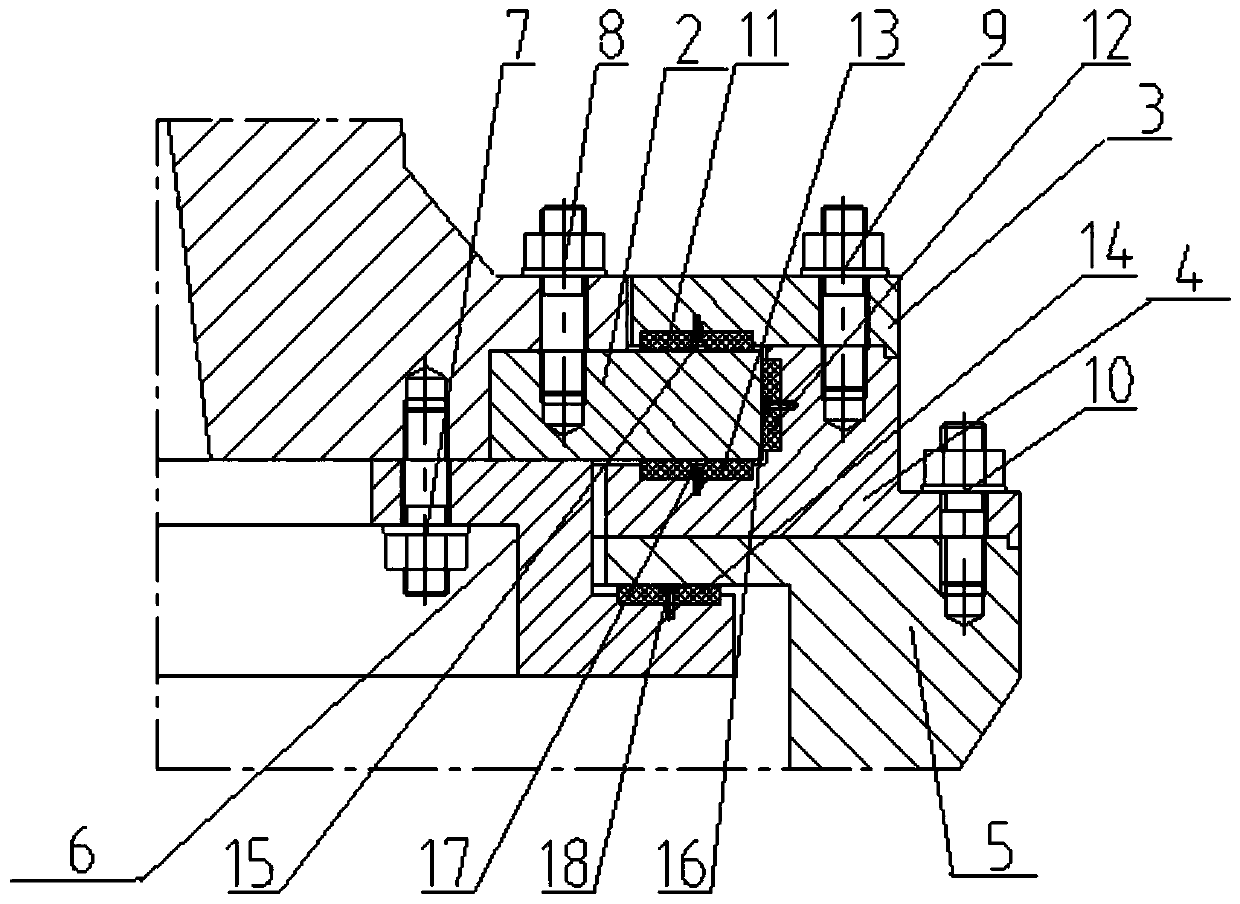

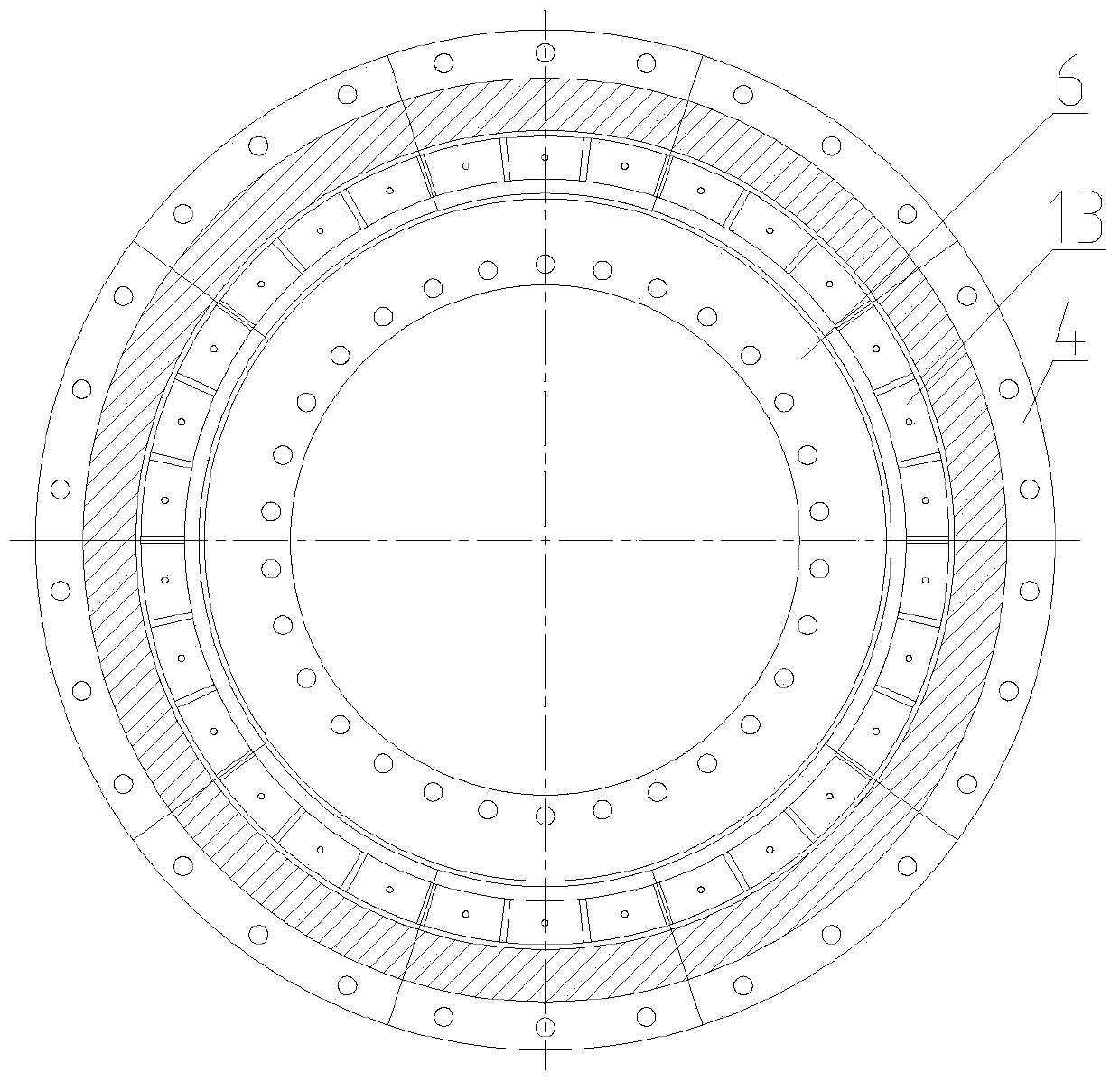

[0028] Such as figure 1 As shown, the present invention proposes a single-point mooring yoke joint structure that can replace bearings at sea, including a nose cone 1, an inner ring 2, an upper outer ring 3, a middle outer ring 4, a lower outer ring 5 and auxiliary Bearing seat 6.

[0029] The lower end of the nose cone 1 is provided with an inner ring 2, the inner ring 2 is circular, and is fixed to the outer periphery of the lower end of the nose cone 1 by inner ring bolts 8. The upper surface, the outer surface and the lower surface of the inner ring 2 are respectively provided with an upper outer ring 3 and a middle outer ring 4 . The upper outer ring 3 is two semi-annular rings, which are arranged above the two sides of the inner ring 2 respectively. The inner side of the lower surface of the upper outer ring 3 is provided with...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - Generate Ideas

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com