Low-resilience and anti-powder-falling silica gel heat-conducting gasket and preparation method thereof

A heat-conducting gasket and low-rebound technology, applied in the field of thermal interface materials, can solve problems such as difficult to control the compression degree of silicone heat-conducting gaskets, affect the heat dissipation performance of electronic products, and unsatisfactory heat conduction effects, and achieve particle size reduction and compressibility The effect of reducing the property and resilience and facilitating the demolding

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1-3

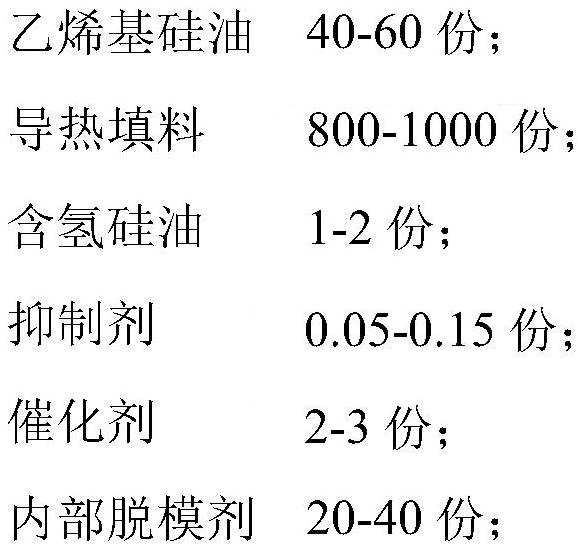

[0047] Provide a low-rebound, powder-free silicone thermal pad, which is prepared according to the dosage in Table 2 using the following scheme:

[0048] Add vinyl silicone oil and thermal conductive filler into the kneader and stir for 45 minutes, then add alkynyl cyclohexanol, hydrogen-containing silicone oil, platinum catalyst, internal mold release agent and silicone powder in turn and stir for 60 minutes; put the mixture into the calender, and Calendered in a vacuum environment of -0.1MPa, and then baked in an oven at 120°C for 30 minutes to obtain a fully cured large piece of low-rebound, non-powder-dropping silicone thermal pad, and finally the large piece of low-rebound, non-powder-dropping The silicone thermal pad is cut to the specified size.

[0049] Among them, the viscosity of the vinyl silicone oil is 200 mPa·s, and the viscosity of the hydrogen-containing silicone oil is 500 mPa·s.

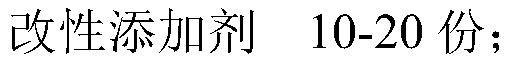

[0050] The thermally conductive filler is micron-sized alumina, and its partic...

Embodiment 4-7

[0055] Embodiments 4-7 provide a low-rebound, non-powder-dropping silica gel heat-conducting gasket, which is different from Embodiment 3 in that the particle size ratio of micron-sized alumina is different. See Table 3 for the proportions of micron-sized aluminas with different particle sizes in Examples 4-7.

[0056] Table 3: Proportioning ratios of micron-sized aluminas with different particle sizes in Examples 4-7

[0057]

Embodiment 8-12

[0059] Embodiments 8-12 provide a low-rebound, non-powder-dropping silica gel thermal pad. The difference from Embodiment 7 is that the thermally conductive filler used is a combination of micron-sized alumina and micron-sized aluminum nitride, and in some embodiments Add nano-scale aluminum nitride with a particle size of 50-100nm. The proportions of micron-sized aluminum oxide, micron-sized aluminum nitride and nano-sized aluminum nitride in Examples 8-12 are shown in Table 4 below.

[0060] Table 4: Proportions of each component thermally conductive filler in Examples 8-12 (unit: g)

[0061] Example 8 Example 9 Example 10 Example 11 Example 12 Micron alumina 450 690 680 680 680 Micron Aluminum Nitride 440 200 210 210 210 Nanoscale Aluminum Nitride 0 0 10 80 45

PUM

| Property | Measurement | Unit |

|---|---|---|

| particle diameter | aaaaa | aaaaa |

| viscosity | aaaaa | aaaaa |

| viscosity | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - Generate Ideas

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com