Heat dissipation system for high-voltage frequency converter of desulfurization and denitrification induced draft fan

A high-voltage frequency converter and heat dissipation system technology, applied in cooling/ventilation/heating transformation, chemical instruments and methods, power electronics modification, etc., can solve the problems of easy burning of fan motors, insufficient ventilation area, and easy damage of air-conditioning compressors and other problems to achieve the effect of avoiding over-temperature burning, avoiding long-term operation, and ensuring heat dissipation performance

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0024] In order to deepen the understanding of the present invention, the present invention will be further described below in conjunction with the examples, which are only used to explain the present invention, and do not constitute a limitation to the protection scope of the present invention.

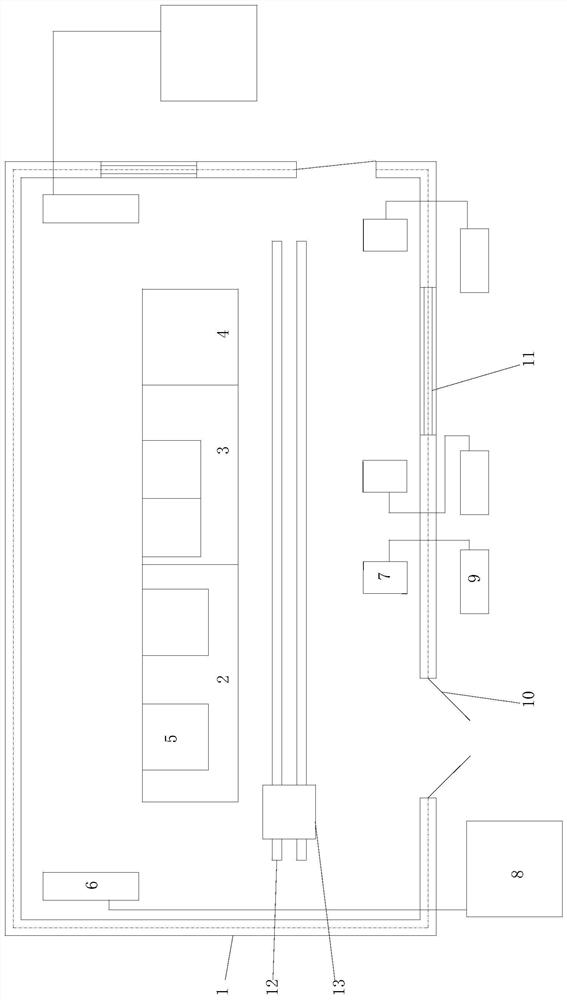

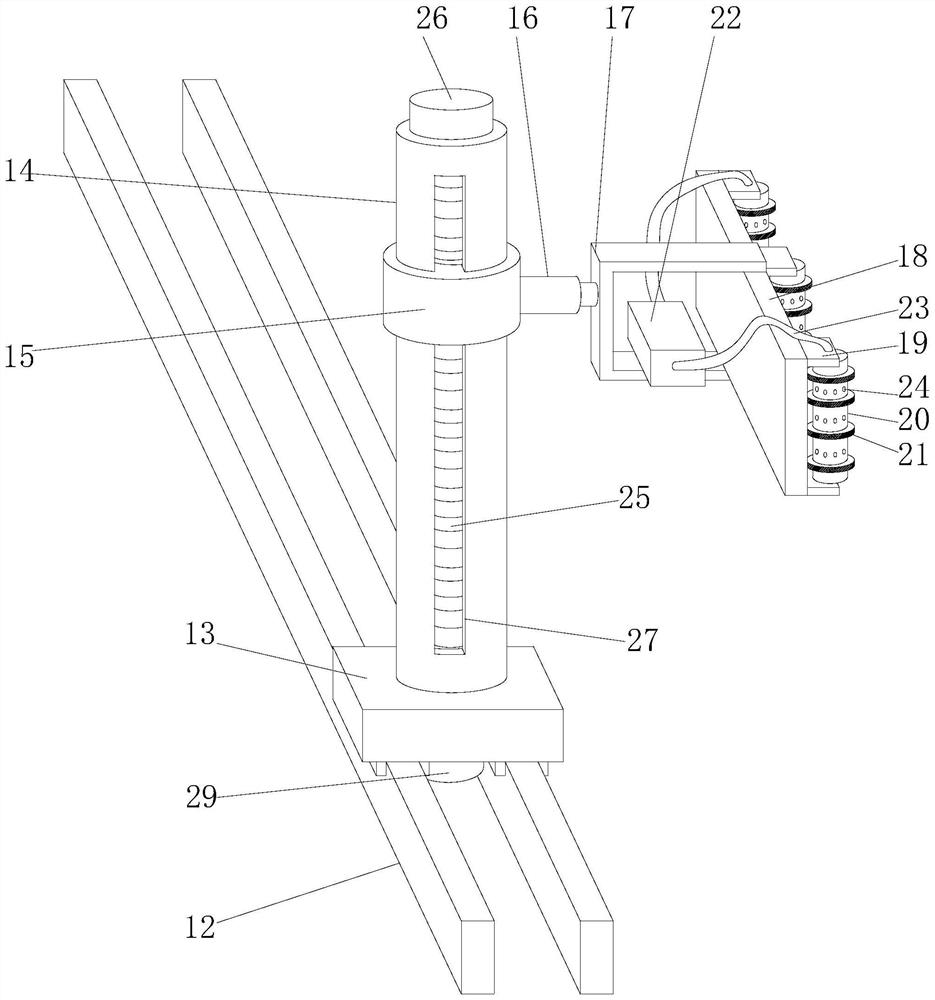

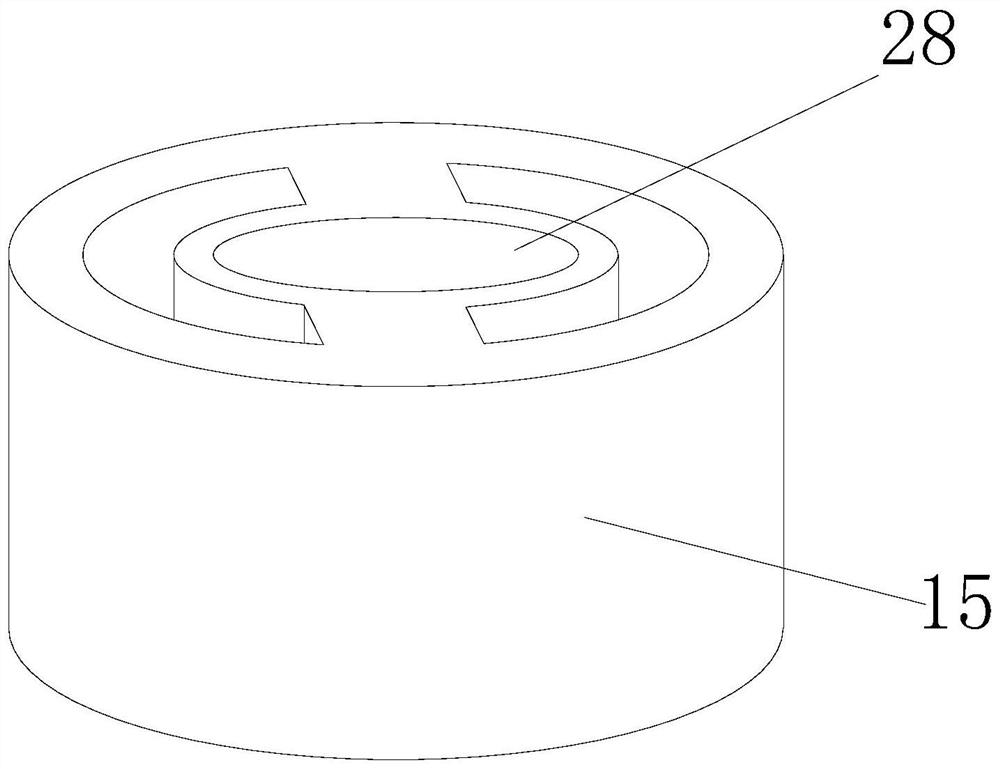

[0025] according to figure 1 , 2 , 3, this embodiment proposes a desulfurization and denitrification induced draft fan high-voltage frequency converter heat dissipation system, including a frequency converter component and a heat dissipation component, the frequency converter component is located inside the control room 1, and the frequency converter component includes a transformer cabinet 2. The power unit cabinet 3 and the switching cabinet 4, the transformer cabinet 2 and the power unit cabinet 3 are equipped with cabinet top fans 5, the heat dissipation components include a 10P air conditioner 6 and a 5P air conditioner 7, and the 10P air conditioner 6 is located in the The tw...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com