Negative electrode slurry dry-type preparation method

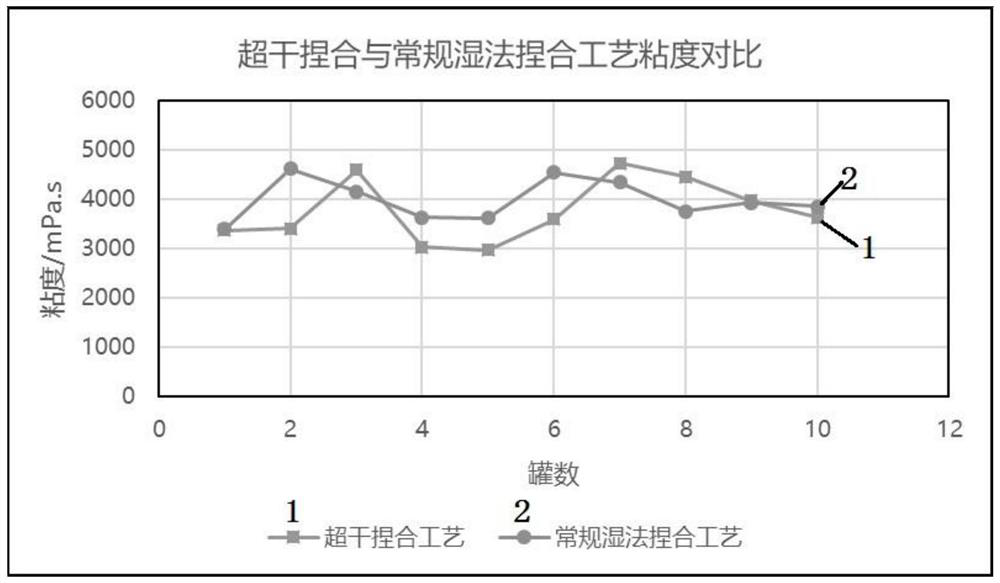

A negative electrode slurry, dry-type technology, applied in the field of dry-type preparation of negative electrode slurry, can solve the problems that the glue dispersion cannot be guaranteed, the overall stability of the slurry is at risk, and the overall production efficiency is reduced, so as to increase the utilization of the plant The effect of reducing the mixing rate, reducing the mixing steps, and shortening the mixing time

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

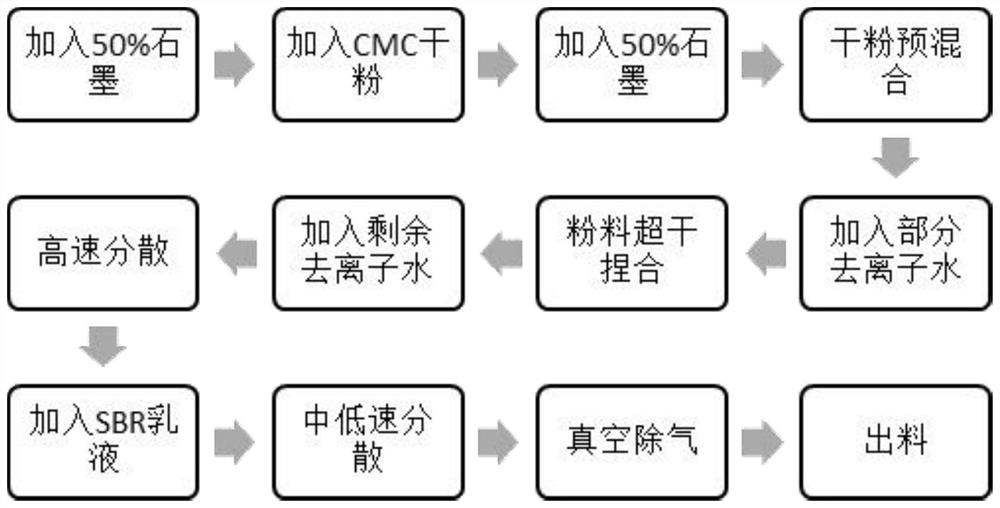

[0031] A dry preparation method for negative electrode slurry, the preparation process steps are as follows figure 1 shown, including the following steps:

[0032] S1. Mix and stir the negative electrode active material and the thickener to obtain the first premix;

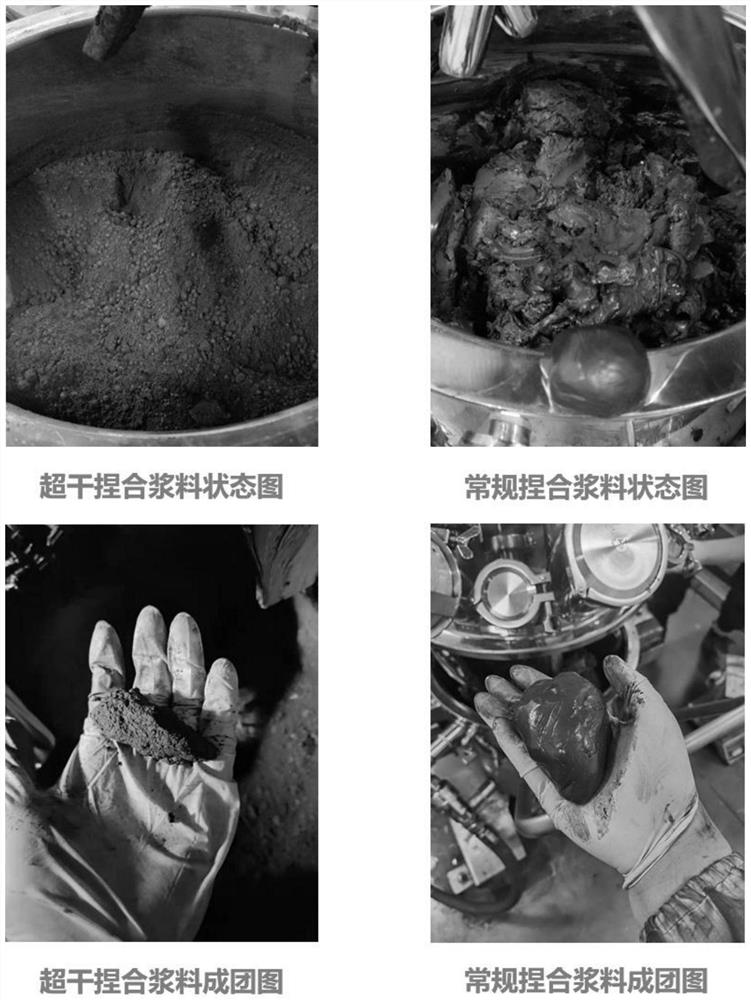

[0033] S2. Add part of the solvent into the first premix, stir, and dry knead to obtain the second premix;

[0034] S3. Add the remaining solvent into the second premix and stir to disperse to obtain the third premix;

[0035] S4. Add the binder into the third premix, stir and disperse, and reverse the stirring to remove the gas to prepare the negative electrode slurry.

[0036] Wherein, the stirring revolution speed in S1 is 15 rpm, and the dispersion time is 30 min.

[0037] Wherein, the ratio of parts by weight of the negative electrode active material, the thickener and the binder is 97.4:1.2:1.4.

[0038] Wherein, the parts by weight of the solvent added in the S2 is 35 parts, the solid content of the se...

Embodiment 2

[0042] The difference with embodiment 1 is:

[0043] Wherein, the ratio of parts by weight of the negative electrode active material, the thickener and the binder is 97.7:0.9:1.4.

[0044] The rest are the same as in Embodiment 1, and will not be repeated here.

Embodiment 3

[0046] The difference with embodiment 1 is:

[0047] Wherein, the ratio of parts by weight of the negative electrode active material, the thickener and the binder is 96.6:1.4:2.0.

[0048] The rest are the same as in Embodiment 1, and will not be repeated here.

PUM

| Property | Measurement | Unit |

|---|---|---|

| viscosity | aaaaa | aaaaa |

| viscosity | aaaaa | aaaaa |

| viscosity | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com