Series voltage-dividing type discharging device

A discharge device, series voltage dividing technology, applied in transformer/inductor parts, circuits, transformer/inductor coils/windings/connections, etc. The effect of core weight, material cost reduction, and terminal voltage reduction

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0024] The preferred embodiments of the present invention will be described in detail below in conjunction with the accompanying drawings, so that the advantages and features of the present invention can be more easily understood by those skilled in the art, so as to define the protection scope of the present invention more clearly.

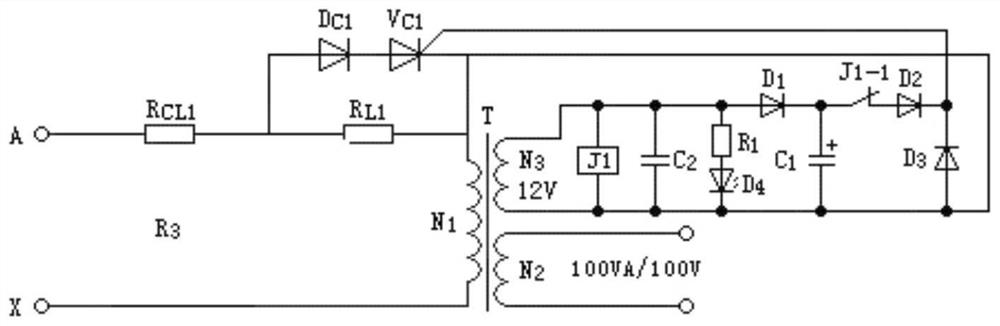

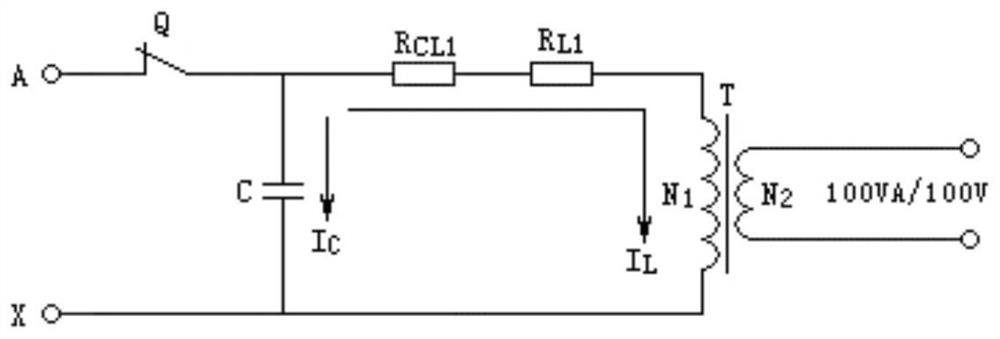

[0025] refer to figure 2 As shown, this embodiment discloses a series voltage-dividing discharge device, including a main circuit and a trigger circuit, and the main circuit includes a current-limiting resistor R CL1 , Steady-state voltage divider resistor R L1 , voltage divider diode D C1 and transfer control switch V C1 ; The current limiting resistor R CL1 One end of the steady-state voltage divider resistor R L1 One end of the voltage divider diode D C1 anode connection, the steady-state divider resistor R L1 The other end is connected to the primary winding N of the sampling transformer T 1 Connected at one end, the voltage divider d...

PUM

| Property | Measurement | Unit |

|---|---|---|

| electrical resistance | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - Generate Ideas

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com