Mechanical part surface defect detection method based on image processing

A technology for mechanical parts and defect detection, applied in the field of image processing, can solve the problems of affecting the defect detection effect, difficult to identify different types of defects, and unable to adapt to self-adaptation, and achieve the effect of improving the defect detection effect.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

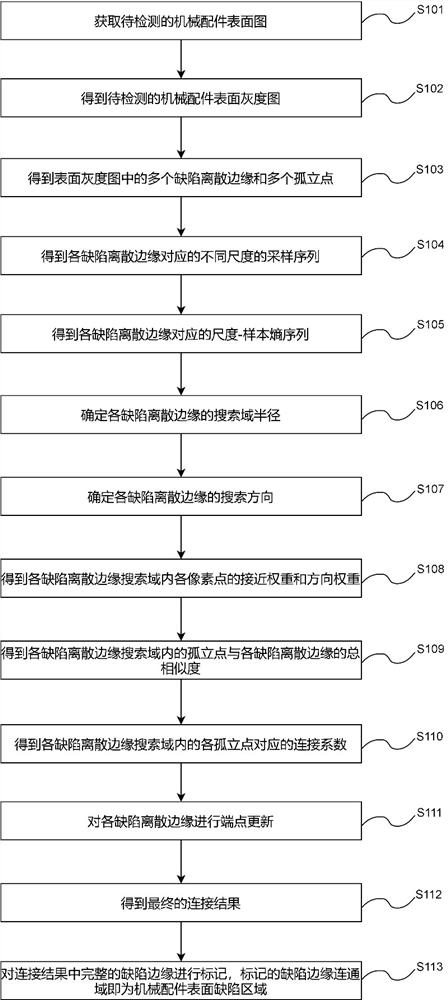

[0060] An embodiment of the present invention provides a method for detecting surface defects of mechanical parts based on image processing, such as figure 1 shown, including:

[0061] S101. Obtain a surface map of the mechanical part to be detected.

[0062] Among them, the surface map of the mechanical parts to be detected refers to the acquisition when it is necessary to detect cracks and scratches on the surface of the mechanical parts.

[0063] S102. Perform grayscale processing on the surface map of the mechanical part to obtain a grayscale map of the surface of the mechanical part.

[0064] Among them, the grayscale image is also called the grayscale image. The logarithmic relationship between white and black is divided into several levels, called gray scale. The gray scale is divided into 256 levels.

[0065] S103. Perform canny edge detection on the surface grayscale image of the mechanical parts, and obtain multiple defect discrete edges and multiple isolated poi...

Embodiment 2

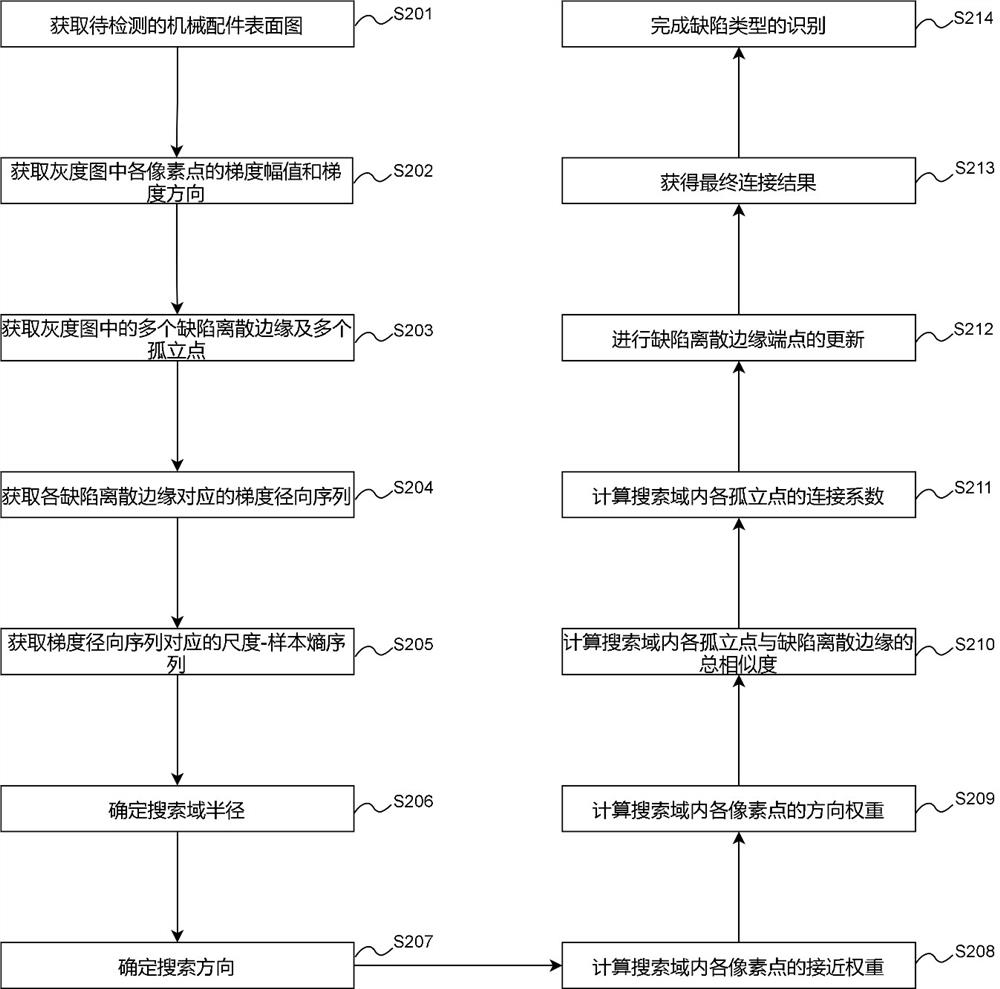

[0091] An embodiment of the present invention provides a method for detecting surface defects of mechanical parts based on image processing, such as figure 2 shown, including:

[0092] S201. Obtain a surface map of the mechanical part to be detected.

[0093] Under the influence of complex imaging factors such as illumination and shooting angle, the edge pixel values of the same thing are not the same, the gradient changes of its pixels will be affected to varying degrees, and the gradient strengths of its edge points are also different, which leads to the canny algorithm When the edge is detected, the edge is discrete, that is, the same real edge will appear discontinuous after being detected by the canny operator. At this time, the discontinuous edge will affect the detection effect of the canny algorithm, for example, when it is necessary to detect In scenarios such as cracks and scratches on the surface of parts, it is necessary to mark the complete crack or scratch in...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com