Chemical safety production monitoring method and system based on temperature sensing

A technology for safe production and monitoring systems, applied in the Internet of Things-related fields, which can solve problems such as low efficiency, labor, and strong instability

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

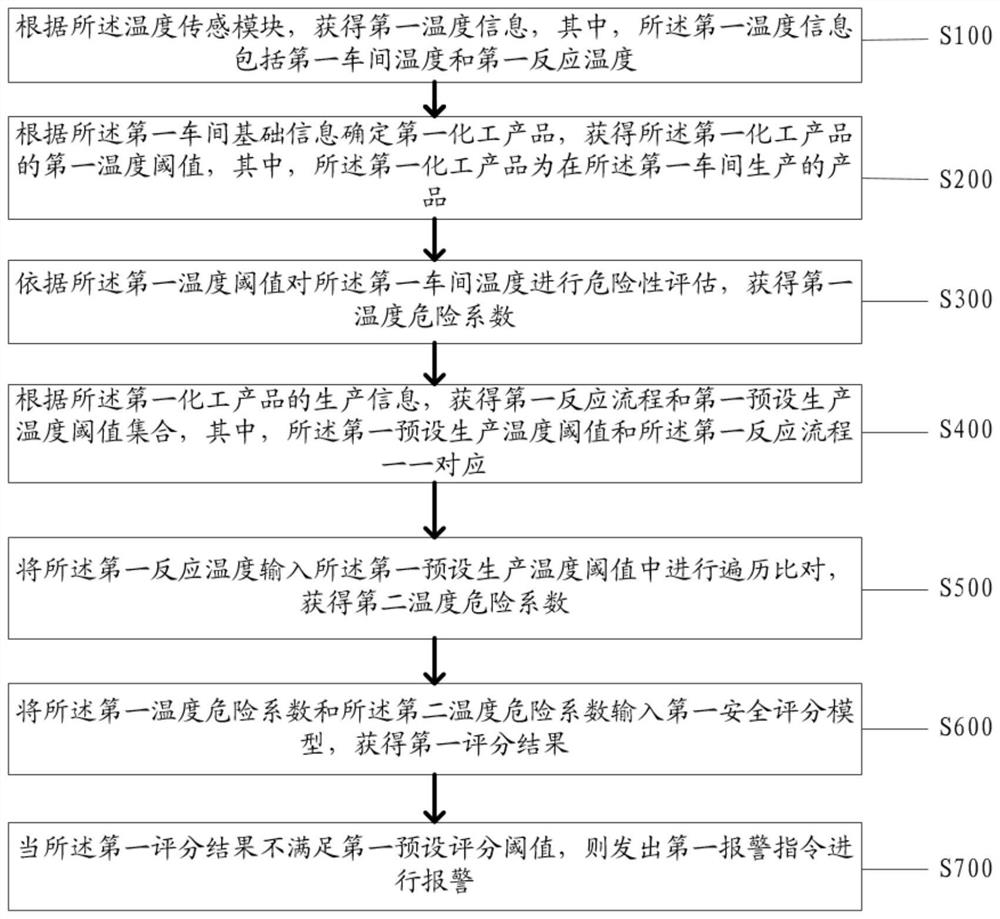

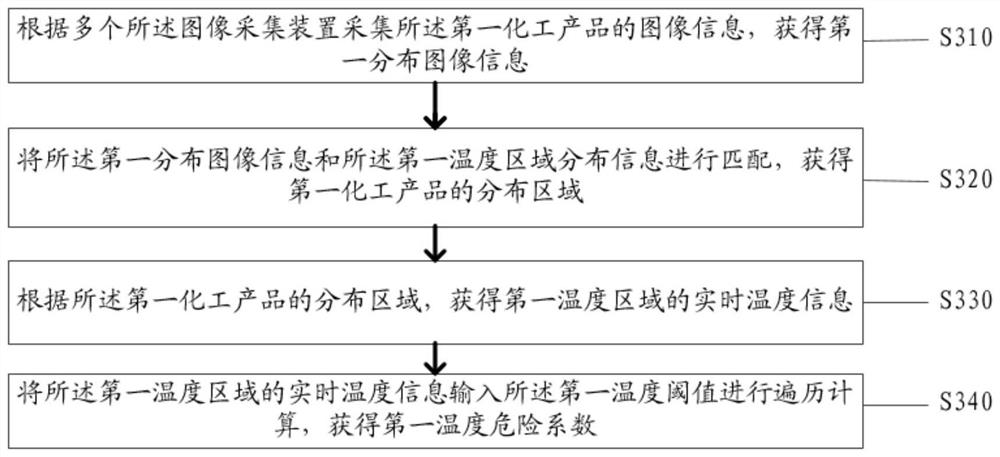

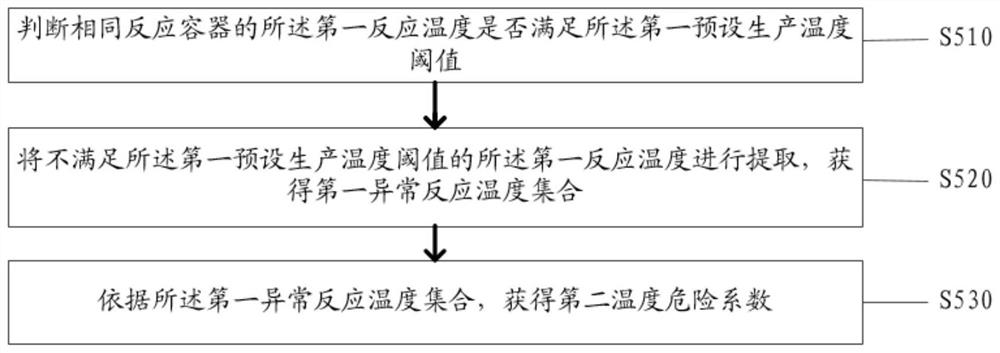

[0027] Such as figure 1 As shown, the embodiment of the present application provides a chemical safety production monitoring method based on temperature sensing, wherein the method is applied to a chemical safety production monitoring system, the system includes a temperature sensing module, and the method include:

[0028] S100: Obtain first temperature information according to the temperature sensing module, wherein the first temperature information includes a first workshop temperature and a first reaction temperature;

[0029] Specifically, the temperature sensing module is composed of a plurality of temperature sensors. Preferably, a plurality of high temperature sensors are deployed in the reaction vessel to collect reaction temperature information, and a plurality of conventional temperature sensors are deployed in different positions of the workshop to collect the reaction temperature information. Comprehensive temperature information; the first workshop is a producti...

Embodiment 2

[0082] Based on the same inventive concept as that of a temperature-sensing-based chemical safety production monitoring method in the foregoing embodiments, as Figure 4 As shown, the embodiment of the present application provides a chemical safety production monitoring system based on temperature sensing, wherein the system includes:

[0083] A first obtaining unit 11, the first obtaining unit 11 is configured to obtain first temperature information according to the temperature sensing module, wherein the first temperature information includes a first workshop temperature and a first reaction temperature;

[0084] The second obtaining unit 12, the second obtaining unit 12 is used to determine the first chemical product according to the first workshop basic information, and obtain the first temperature threshold of the first chemical product, wherein the first chemical product For products produced in said first workshop;

[0085] A first evaluation unit 13, configured to eva...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com