Modified polyester transparent composite material and preparation method thereof

A composite material and modified polyester technology, applied in the field of polymer materials, can solve the problems of decreased physical and mechanical properties, large haze, affecting the application of polyester materials, etc., and achieve good physical and mechanical strength and toughness, low haze, The effect of high industrial application value

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

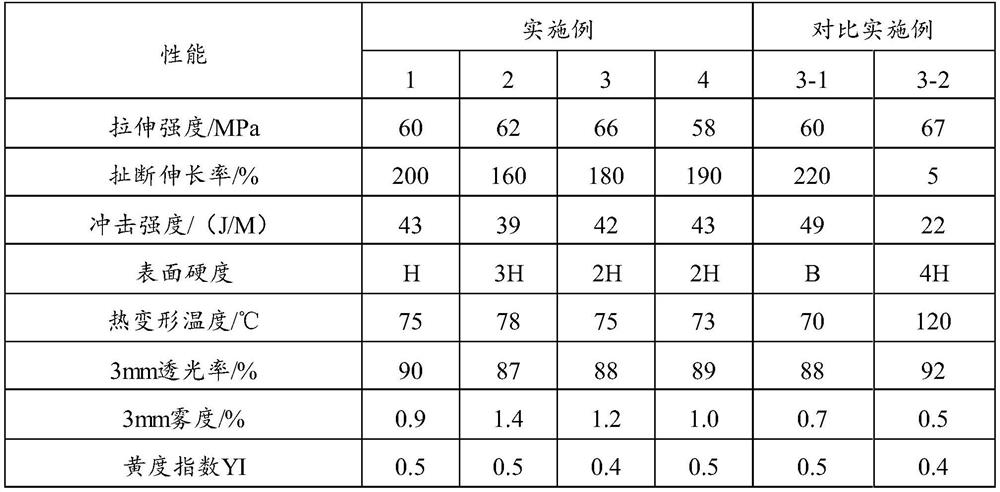

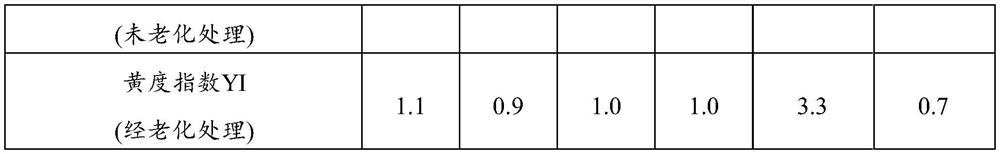

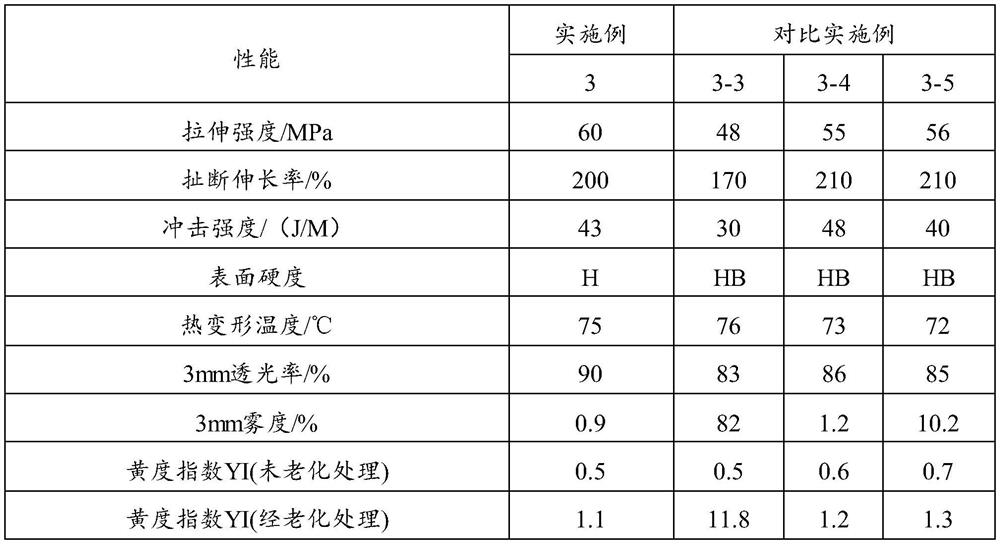

Examples

Embodiment 1

[0065] The concrete steps of modified polyester transparent composite material are:

[0066] Crystalline destruction of polyester resin: pre-dry the polyester resin in an oven at 110°C for 5 hours to remove moisture, melt and extrude through a twin-screw extruder, and air-cool and pelletize to obtain an amorphous polyester resin with crystallization destruction. The extrusion temperature of the twin-screw extruder is 250° C., and the extrusion speed is 60 rpm.

[0067] Drying treatment of polyester resin: immediately transfer the amorphous polyester resin obtained in the previous step to a drying device, and dry to remove moisture for later use. The drying equipment is an infrared oven, and the drying condition is 65° C. for 8 hours.

[0068] Pretreatment of the methyl methacrylate polymer and the compatibilizer: the methyl methacrylate polymer and the compatibilizer are dried separately to remove moisture, and then set aside. The drying condition is an infrared oven, and th...

Embodiment 2

[0075] Crystalline destruction of polyester resin: pre-dry the polyester resin in an oven at 140°C for 2 hours to remove moisture, melt and extrude through a twin-screw extruder, and air-cool and pelletize to obtain an amorphous polyester resin with crystallization destruction. The extrusion temperature of the twin-screw extruder is 300° C., and the extrusion speed is 120 rpm.

[0076] Drying treatment of polyester resin: immediately transfer the amorphous polyester resin obtained in the previous step to a drying device, and dry to remove moisture for later use. The drying equipment is an infrared oven, and the drying condition is 85° C. for 4 hours.

[0077] Pretreatment of the methyl methacrylate polymer and the compatibilizer: the methyl methacrylate polymer and the compatibilizer are dried separately to remove moisture, and then set aside. The drying condition is an infrared oven, and the drying condition is 105° C. for 2 hours.

[0078] The solid-phase polycondensed pol...

Embodiment 3

[0084] Crystallization destruction of polyester resin: pre-dry the polyester resin in an oven at 120°C for 3 hours to remove moisture, melt and extrude through a twin-screw extruder, and air-cool and pelletize to obtain an amorphous polyester resin with crystallization destruction. The extrusion temperature of the twin-screw extruder is 260° C., and the extrusion speed is 80 rpm.

[0085] Drying treatment of polyester resin: immediately transfer the amorphous polyester resin obtained in the previous step to a drying device, and dry to remove moisture for later use. The drying equipment is an infrared oven, and the drying condition is 70° C. for 6 hours.

[0086] Pretreatment of the methyl methacrylate polymer and the compatibilizer: the methyl methacrylate polymer and the compatibilizer are dried separately to remove moisture, and then set aside. The drying condition is a blast oven, and the drying condition is 90° C. for 4 hours.

[0087] The polyester resin is solid-phase ...

PUM

| Property | Measurement | Unit |

|---|---|---|

| melt flow index | aaaaa | aaaaa |

| melt flow index | aaaaa | aaaaa |

| melt flow index | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com