Damp-heat-resistant thermoplastic polyurethane elastomer material and preparation method thereof

A technology of thermoplastic polyurethane and elastomer materials, applied in the field of polyurethane elastomers, can solve the problems of poor hydrolysis resistance, low temperature resistance and flexibility, polyether TPU mechanical properties, rigidity and wear resistance, etc., and achieve product processing performance Good, low-temperature flexibility, high performance, and high mechanical properties

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

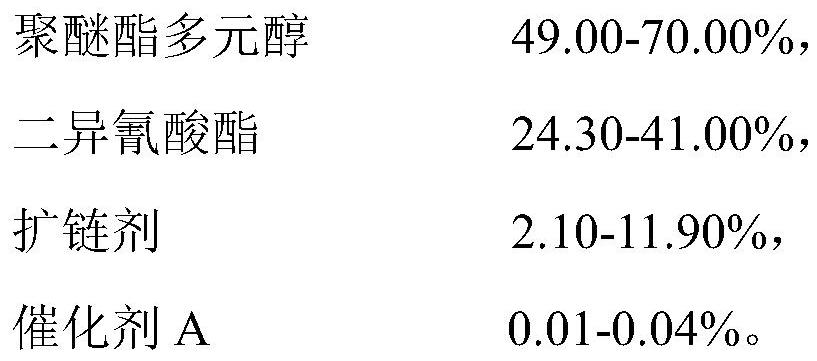

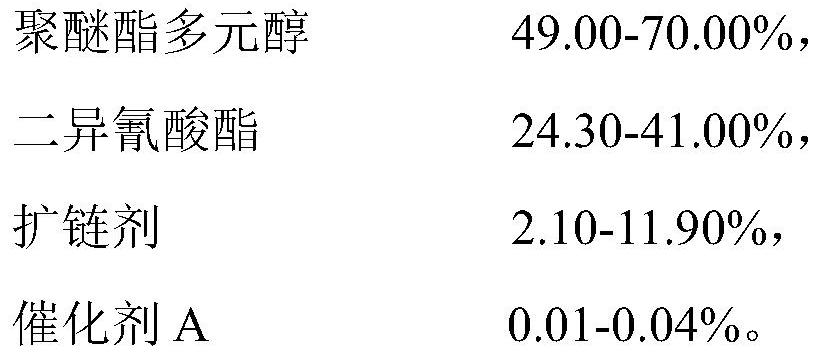

Method used

Image

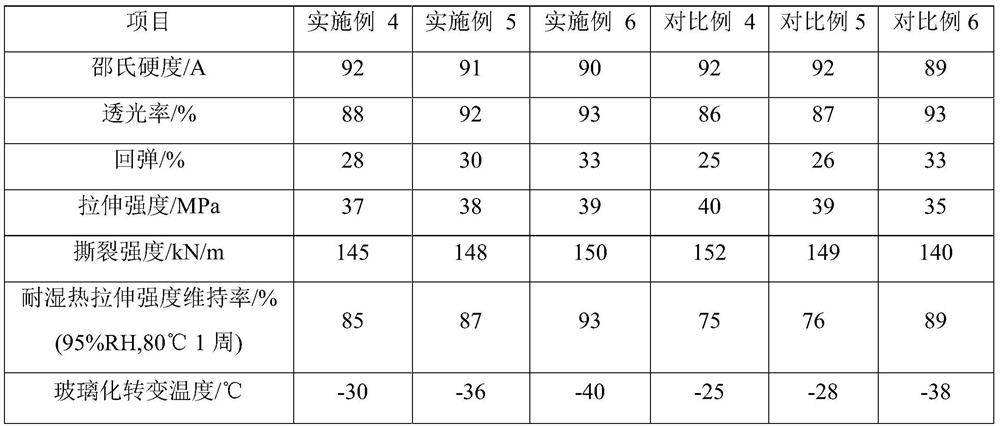

Examples

Example Embodiment

[0023] Example 1

[0024] As follows a number average molecular weight of polyether ester 1000. Polyol A:

[0025] Adipic acid and 1,6-hexanediol in a molar ratio of 1.10 / 1, was added the reaction kettle was heated with stirring, was added by weight of the total weight of polyether polyol and 1,6-hexanediol 5% small molecule, a number average molecular weight 200, a functionality of 2 polyether polyol, and nitrogen protection, the reaction when the water temperature was raised to 140 deg.] C, the control overhead reflux temperature 100 ℃, accounting added adipic acid, 1,6-hexanediol, and small molecules the total mass of the polyether polyol alcohol 0.005% of tetrabutyl titanate, the temperature was raised to 220 deg.] C, reacted for 2 hours, and then nitrogen bubbling process the condensation water produced by extrusion, the material within the vessel when the acid value is less than 0.6mgKOH / g, a water content of 0.05% or less, a hydroxyl value of viscosity or qualified, i.e...

Example Embodiment

[0026] Example 2

[0027] As it follows a number average molecular weight of 1500 polyether ester polyol B:

[0028] Adipic acid and 1,6-hexanediol in a molar ratio of 1.10 / 1, was added the reaction kettle was heated with stirring, was added 10% by weight of the total weight of polyether polyol and 1,6-hexanediol small molecule, a number average molecular weight 500, a functionality of 2 polyether polyol, and nitrogen protection, the reaction when the water temperature was raised to 140 deg.] C, overhead temperature 102 controls deg.] C to reflux, was added accounted adipic acid, 1,6-hexanediol, and small molecules the total mass of the polyether polyol alcohol 0.005% of tetrabutyl titanate, the temperature was raised to 230 deg.] C, for 3 hours, then nitrogen bubbling process the condensation water produced by extrusion, the material within the vessel when the acid value is less than 0.6mgKOH / g, a water content of 0.05% or less, a hydroxyl value of viscosity or qualified, i.e...

Example Embodiment

[0029] Example 3

[0030] As it follows a number average molecular weight of 2000 polyether polyol C:

[0031] Adipic acid and 1,6-hexanediol in a molar ratio of 1.10 / 1, was added the reaction kettle was heated with stirring, was added 20% by weight of the total weight of polyether polyol and 1,6-hexanediol small molecule, a number average molecular weight 800, a functionality of 2 polyether polyol, and nitrogen protection, the reaction when the water temperature was raised to 140 deg.] C, the control overhead reflux temperature 100 ℃, accounting added adipic acid, 1,6-hexanediol, and small molecules the total mass of the polyether polyol alcohol 0.005% of tetrabutyl titanate, the temperature was raised to 220 deg.] C, for 3 hours, then nitrogen bubbling process the condensation water produced by extrusion, the material within the vessel when the acid value is less than 0.6mgKOH / g, a water content of 0.05% or less, a hydroxyl value of viscosity or qualified, i.e. qualified pro...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Glass transition temperature | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com