POSS (polyhedral oligomeric silsesquioxane) modified high-hardness water-proof alkyd resin and preparation method thereof

An alkyd resin and high hardness technology, applied in the field of water-based functional resins, can solve the problems of easy yellowing of the coating film, poor storage stability, and decreased storage stability of the coating, and achieve excellent hydrolysis resistance, excellent wear resistance, and excellent storage The effect of stability

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

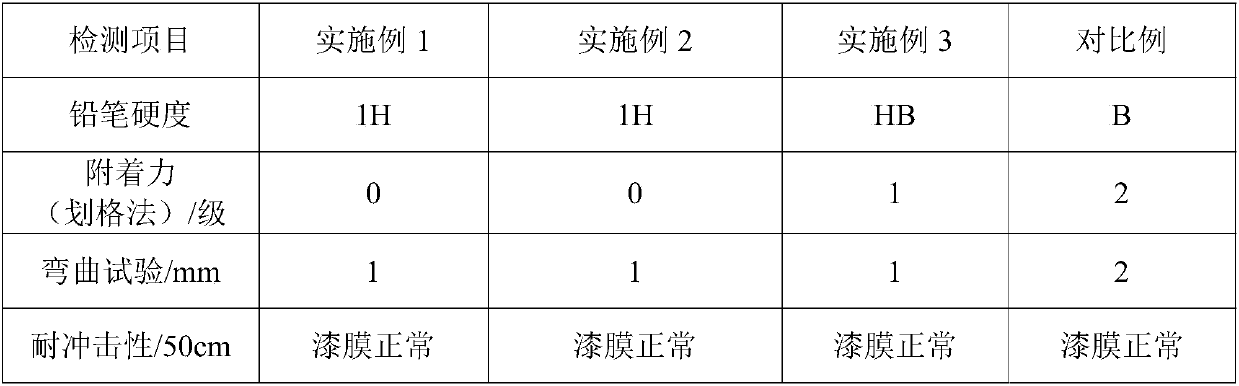

Embodiment 1

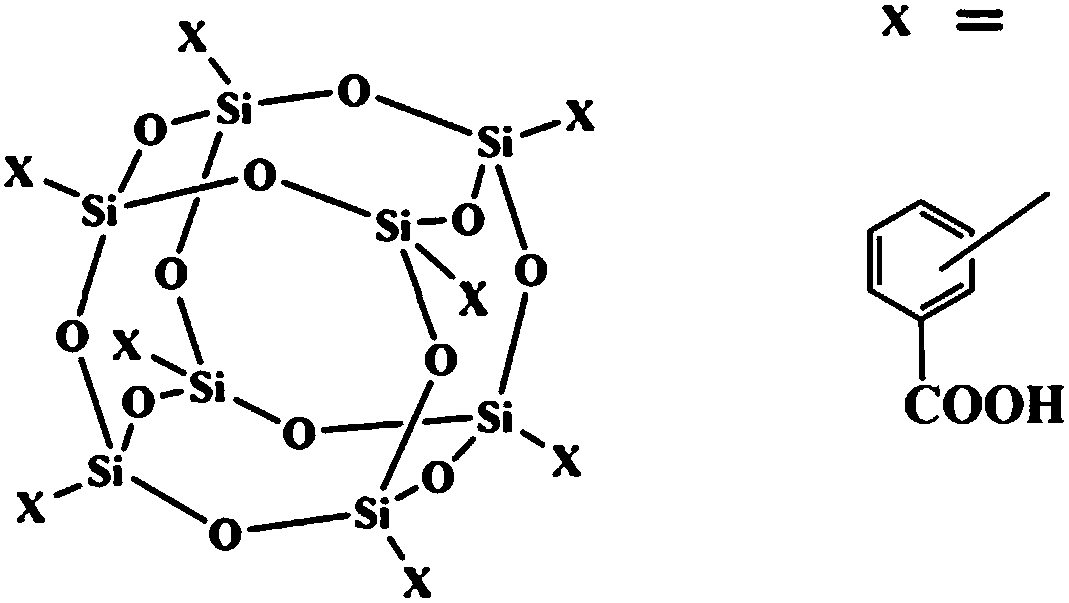

[0022] A POSS modified high-hardness water-resistant alkyd resin, its composition is in parts by mass: 42.0 parts of linseed oil, 6.0 parts of propylene glycol, 6.0 parts of trimethylolethane, 9.0 parts of phthalic anhydride, 6.0 parts Parts of isopropylboronic acid, 3.0 parts of hexa-carboxyphenyl POSS, 0.05 parts of dibutyltin oxide chloride, 5.0 parts of N,N-dimethylethanolamine, 65.0 parts of deionized water;

[0023] Its preparation method is as follows: in N 2 Under protection, add 21.0 parts of linseed oil, 3.0 parts of propylene glycol, 3.0 parts of trimethylolethane, 3.0 parts of isopropyl boric acid and 0.02 parts of dibutyltin oxide chloride into the reaction kettle, heat to 150 °C, and keep warm Turn off the N after 8 hours of reaction 2 , and then add 9.0 parts of phthalic anhydride, 21.0 parts of linseed oil, 3.0 parts of propylene glycol, 3.0 parts of trimethylolethane, 3.0 parts of six-p-carboxyphenyl POSS, 3.0 parts of isopropyl boric acid and 0.03 parts Par...

Embodiment 2

[0025] A POSS modified high-hardness water-resistant alkyd resin, its composition in parts by mass: 45.0 parts of tung oil, 10.0 parts of propylene glycol, 5.0 parts of pentaerythritol, 10.0 parts of terephthalic anhydride, 8.0 parts of triisopropyl borate , 3.0 parts of hexa-carboxyphenyl POSS, 0.15 parts of monobutyl tin trichloride, 8.0 parts of triethylamine, 65.0 parts of deionized water;

[0026] Its preparation method is as follows: in N 2 Under protection, add 15.0 parts of tung oil, 5.0 parts of propylene glycol, 2.0 parts of pentaerythritol, 3.0 parts of triisopropyl borate and 0.05 parts of monobutyl tin trichloride into the reaction kettle, heat to 180 ° C, keep warm for 5 hours and then turn off the N 2 , then add 10.0 parts of terephthalic anhydride, 30.0 parts of tung oil, 5.0 parts of propylene glycol, 3.0 parts of pentaerythritol, 3.0 parts of six-p-carboxyphenyl POSS, 5.0 parts of triisopropyl borate and 0.10 parts of monobutyl tri Tin chloride, through N 2...

Embodiment 3

[0028] A POSS modified high-hardness water-resistant alkyd resin, the composition of which is: 35.0 parts of soybean oil, 14.0 parts of ethylene glycol, 8.5 parts of tetrahydrophthalic anhydride, 6.0 parts of phenylboronic acid, 5.0 parts of hexa-carboxyl Phenyl POSS, 0.08 parts of dibutyltin dilaurate, 5.0 parts of 2-amino-1-propanol, 70.0 parts of deionized water;

[0029] Its preparation method is as follows: in N 2 Under protection, 15.0 parts of soybean oil, 5.0 parts of ethylene glycol, 2.5 parts of phenylboronic acid and 0.03 parts of dibutyltin dilaurate were added to the reaction kettle, heated to 140°C, kept warm for 9 hours, and then turned off the N 2 , then add 8.5 parts of tetrahydrophthalic anhydride, 20.0 parts of soybean oil, 9.0 parts of ethylene glycol, 5.0 parts of six-p-carboxyphenyl POSS, 3.5 parts of phenylboronic acid and 0.05 parts of dibutyltin dilaurate in the reactor, pass into N 2 , control the reaction temperature at 140°C, keep the temperature ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com