High-efficiency low-scale polymerization inhibition process for extracting and separating C5 by DMF (Dimethyl Formamide) method

An extraction and high-efficiency technology, applied in the field of high-efficiency and low-scaling polymerization inhibition process, can solve the problems of small tar by-production, slow scaling, slow filter clogging, etc.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

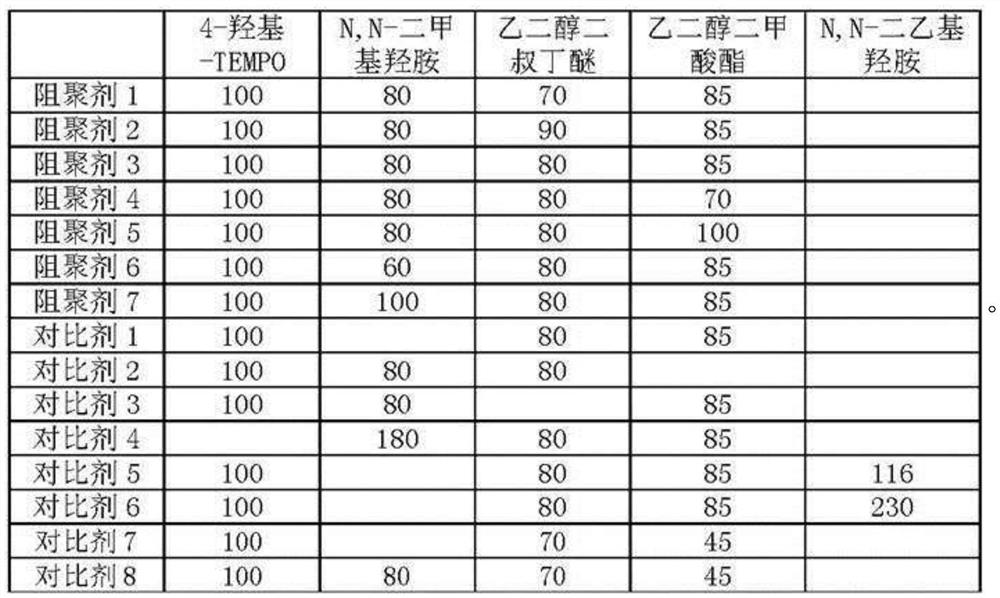

[0024] The present invention will be further described below in conjunction with a polymerization inhibitor, but it does not constitute a limitation of the present invention.

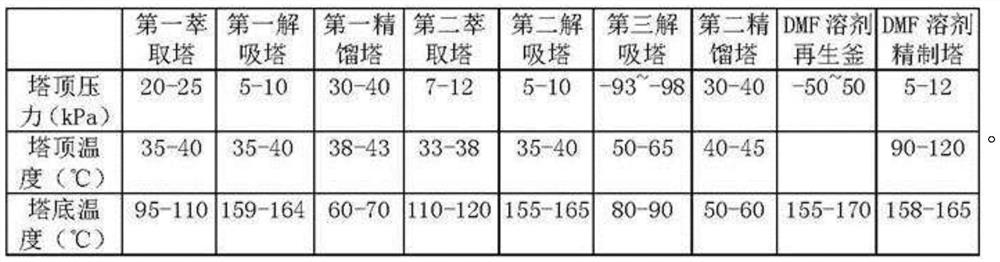

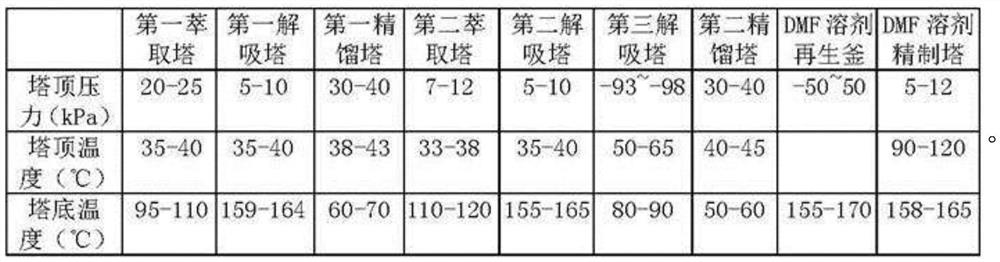

[0025] In multiple sets of parallel and consistent C5 extraction and rectification evaluation test devices, the application effects of each polymerization inhibitor and contrast agent listed in Table 2 are evaluated successively, and each set of extraction and rectification evaluation test devices includes a series operation An extractive rectification column, an analytical rectification column and a carbon five rectification column, simulate the operating conditions of the first extractive rectification column, the first analytical column and the first rectification column of the DMF extraction and separation carbon five industrial plant, And with the carbon five feed that takes from the first extractive rectification tower (generate dicyclopentadiene by thermal polymerization and remove more than 90% c...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com