High-performance concrete with low shrinkage

A technology of high-performance concrete and shrinkage, which is applied in the field of building materials, can solve the problems of large self-shrinkage, restricting the development and application of ultra-high performance concrete, etc. The effect of hydration volume shrinkage

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

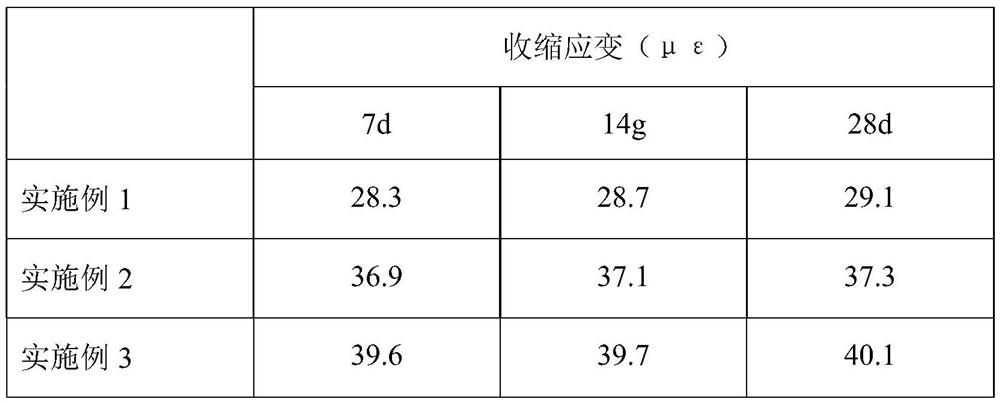

Examples

Embodiment 1

[0030] The present embodiment provides a low-shrinkage high-performance concrete, comprising: 210 parts of cement clinker; 100 parts of modified metakaolin; 30 parts of anhydrite powder; 400 parts of crushed stone; coal ash powder 150 parts; 600 parts of sand; 75 parts of mixed fiber; 13 parts of polycarboxylate superplasticizer; 100 parts of unsaturated polyester resin, 20 parts of admixture; 200 parts of water;

[0031] Among them, the cement clinker powder is mixed with Portland cement clinker powder and high expansibility Belite sulfoaluminate cement clinker powder in a mass ratio of 3:1, and the Portland cement clinker powder is made of ordinary Portland cement The clinker is ground to a specific surface area of 385m 2 / kg, high expansibility Belite sulfoaluminate cement clinker powder is high expansibility Belite sulfoaluminate cement clinker ground to a specific surface area of 500m 2 / kg get;

[0032] The crushed stone is made by mixing small crushed stones and l...

Embodiment 2

[0039] This embodiment provides a kind of high-performance concrete with low shrinkage, comprising: 150 parts of cement clinker powder; 150 parts of modified metakaolin; 40 parts of anhydrite powder; 300 parts of crushed stone; coal ash powder 180 parts; 680 parts of sand; 90 parts of mixed fiber; 17 parts of polycarboxylate superplasticizer; 180 parts of unsaturated polyester resin, 26 parts of admixture; 260 parts of water;

[0040] Among them, the cement clinker powder is mixed with Portland cement clinker powder and high expansibility Belite sulfoaluminate cement clinker powder in a mass ratio of 3:1, and the Portland cement clinker powder is made of ordinary Portland cement The clinker is ground to a specific surface area of 400m 2 / kg to obtain high expansibility Belit sulfoaluminate cement clinker powder, which is ground to a specific surface area of 470m 2 / kg get;

[0041] The crushed stone is made by mixing small crushed stones and large crushed stones of two d...

Embodiment 3

[0048] The present embodiment provides a low-shrinkage high-performance concrete, comprising: 260 parts of cement clinker; 150 parts of modified metakaolin; 50 parts of anhydrite powder; 500 parts of crushed stone; coal ash powder 220 parts; 750 parts of sand; 100 parts of mixed fiber; 22 parts of polycarboxylate superplasticizer; 180 parts of unsaturated polyester resin, 33 parts of admixture; 320 parts of water;

[0049] Among them, the cement clinker powder is mixed with Portland cement clinker powder and high expansibility Belite sulfoaluminate cement clinker powder at a mass ratio of 4:1, and the Portland cement clinker powder is made of ordinary Portland cement The clinker is ground to a specific surface area of 410m 2 / kg obtained, high expansibility Belite sulfoaluminate cement clinker powder is high expansibility Belite sulfoaluminate cement clinker ground to a specific surface area of 520m 2 / kg get;

[0050] The crushed stone is made by mixing small crushed st...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Apparent density | aaaaa | aaaaa |

| Apparent density | aaaaa | aaaaa |

| Diameter | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com