Full-automatic steel pipe cleaning machine with stain removal and rust removal functions

A fully automatic cleaning machine technology, applied in the field of cleaning machines, can solve the problems of waste of resources, inconvenient waste water utilization, inconvenient cleaning of the inner and outer walls of pipes, etc., and achieve the effect of improving the utilization rate

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment

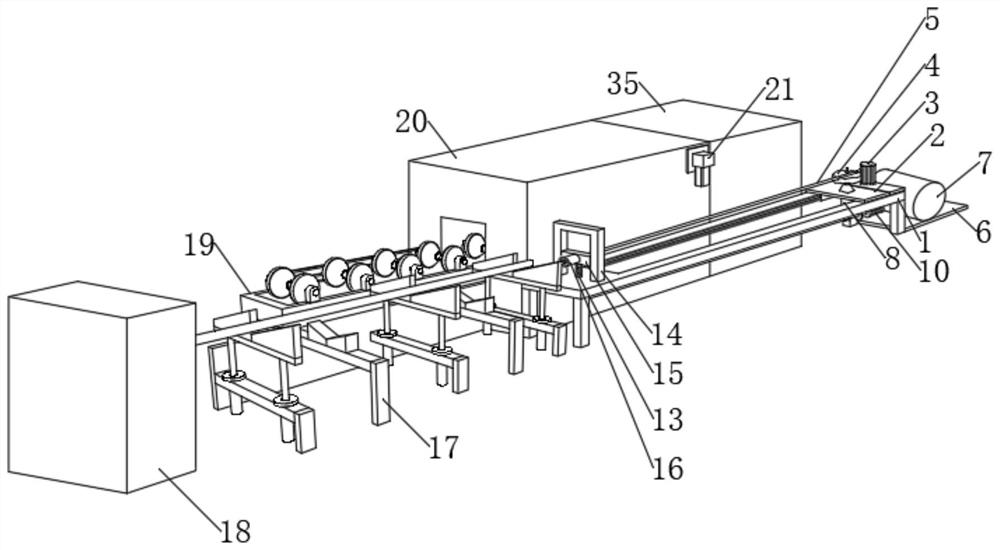

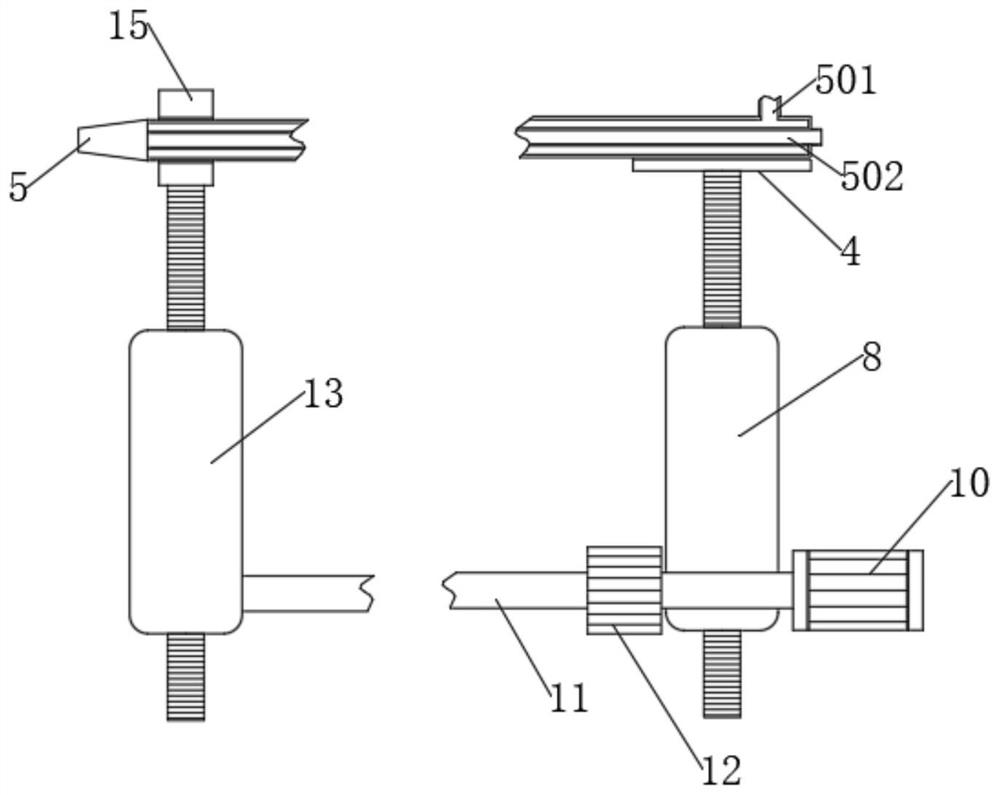

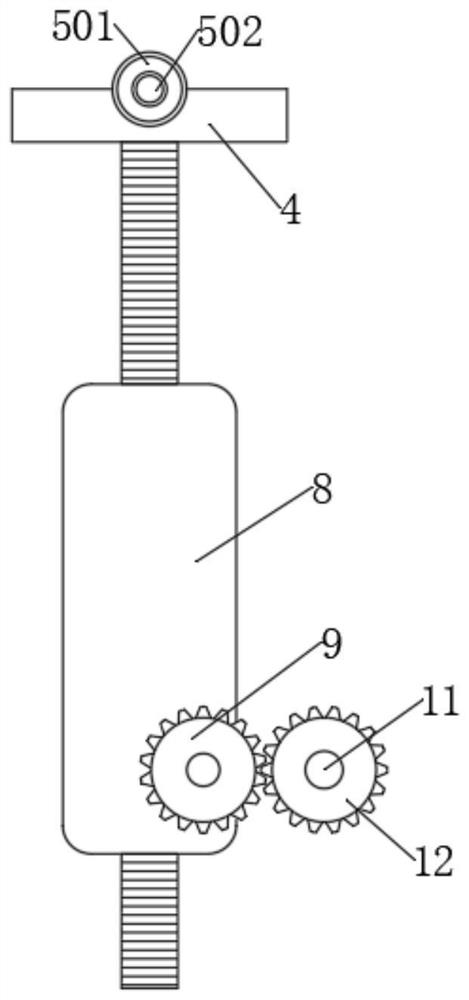

[0041] see Figure 1-4 , a fully automatic steel pipe cleaning machine capable of removing stains and derusting, comprising a slide rail support base 1, the upper end of the slide rail support base 1 is slidably connected to a trolley 2, the upper end of the trolley 2 is electrically connected to a driving motor 3, and the trolley The upper end of 2 is fixedly connected with clamping block 4, the upper end of clamping block 4 is clamped and fixed with inner wall cleaning pipeline 5, the outer end of slide rail support base 1 is fixedly connected with connecting block 6, and the upper end of connecting block 6 is fixedly connected with The clean water pump 7, the lower end of the trolley 2 is fixedly connected with the first turbine screw assembly 8, the output end of the first turbine screw assembly 8 runs through the trolley 2 and is fixedly connected with the clamping block 4, the input end of the first turbine screw assembly 8 The first gear 9 is fixedly connected, the lowe...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com