Processing method for removing harmful substances in vinegar liquid of bamboo and wood and wet tissue liquid and mouth wash prepared by processing method

A technology for bamboo and wood vinegar and harmful substances, which is applied in the directions of medical preparations containing active ingredients, preparations for skin care, oral care, etc. Not widely used and other problems, to achieve the effect of high-value utilization

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

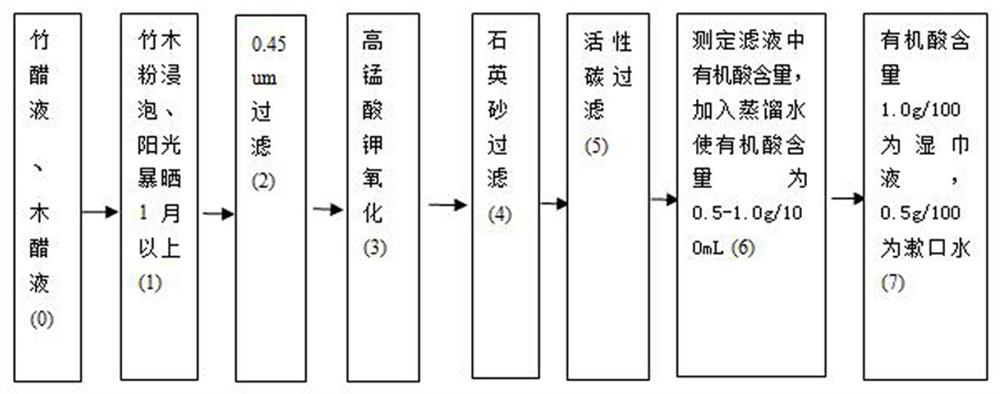

Method used

Image

Examples

Embodiment 1

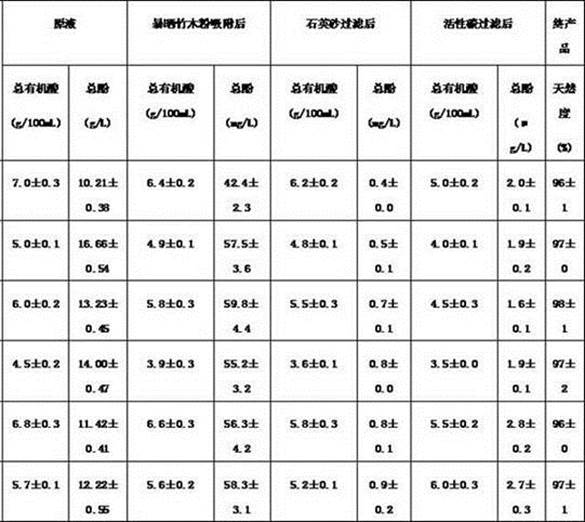

[0035] Take by weighing 10 kilograms of 20 mesh bamboo powder, put into 120 liters of transparent glass container, add 100 kilograms of bamboo vinegar liquid, after standing for 30 days, stir once a day until the bamboo powder is completely suspended and sealed until the color is no longer significantly deepened in 30 days; The filter screen with a pore size of 0.45 μm was filtered at a pressure of 0.1 MPa, and 98 kg of the filtrate was collected; the filtrate was stirred at room temperature at 30 r / min, and potassium permanganate was gradually added until the color disappeared. Mesh SiO 2 ≥99.5% and Fe 2 o 3 ≤0.001% of high-quality natural quartz sand for filtration, and the collected filtrate is 97 kg; the filtrate is filtered with a filter screen with a pore size of 0.45 μm at a pressure of 0.1 MPa, and the filtrate is collected; it is transferred to coconut oil with an iodine value of 800 mg / g and a packing density of 600 g / L. The filter of shell activated carbon is filt...

Embodiment 2

[0037] Take by weighing 10 kilograms of 20 order bamboo powders, put into 120 liters of transparent glass containers, add 100 kilograms of wood vinegar, after standing for 30 days, stir once a day until the bamboo powders are completely suspended and then seal until the color is no longer significantly deepened in 40 days; The filter screen with a pore size of 0.45 μm was filtered at a pressure of 0.1 MPa, and 97 kg of the filtrate was collected; the filtrate was stirred at room temperature at 30 r / min, and potassium permanganate was gradually added until the color disappeared, and 0.4 kg of potassium permanganate was added in total. Mesh SiO 2 ≥99.5% and Fe 2 o 3 ≤0.001% of high-quality natural quartz sand for filtration, and the collected filtrate is 96 kg; the filtrate is filtered with a filter screen with a pore size of 0.45 μm at a pressure of 0.1 MPa, and the filtrate is collected; it is transferred to coconut oil with an iodine value of 800 mg / g and a packing density o...

Embodiment 3

[0039] Weigh 10 kg of 20-mesh wood flour, put it into a 120-liter transparent glass container, add 50 kg of bamboo vinegar and 50 kg of wood vinegar, and leave it for 30 days, stir once a day until the bamboo powder is completely suspended and seal it until the color changes after 35 days Then significantly deepen; filter with a pore size of 0.45 μm filter at a pressure of 0.1 MPa, and collect 96 kg of filtrate; gradually add potassium permanganate to the filtrate under normal temperature stirring at 30 r / min until the color disappears, add 0.3 kg of permanganate Potassium, particle size 80 mesh SiO 2 ≥99.5% and Fe 2 o 3 ≤0.001% of high-quality natural quartz sand for filtration, and the collected filtrate is 95 kg; the filtrate is filtered with a filter screen with a pore size of 0.45 μm at a pressure of 0.1 MPa, and the filtrate is collected; it is transferred to coconut oil with an iodine value of 800 mg / g and a packing density of 600 g / L. The filter of shell activated ca...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Packing density | aaaaa | aaaaa |

| Iodine value | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com