Steaming oven multi-section temperature field control method and system, and storage medium

A control method and technology of a steaming oven, which is applied in the field of temperature control of the steaming oven, can solve problems such as the unstable temperature control process of the steaming oven, and achieve the effects of improving cooking quality, reducing temperature overshoot, and reducing preheating time

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

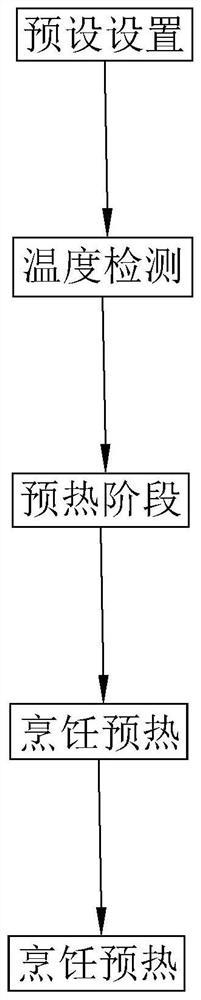

[0068] Embodiment 1. The present invention provides a method for controlling the multi-stage temperature field of a steam oven, such as figure 1 As shown, based on the steam oven with four heating tubes 11 inside, the inside of the steam oven is also provided with a stirring fan 12, and the specific steps are as follows:

[0069] S100, preset setting: receiving the input PID algorithm comparison table, cooking temperature value and preheating target temperature value. The PID algorithm comparison table includes the temperature count, the corresponding switch state of each heating tube 11 and the corresponding relationship of the temperature compensation value. The cooking temperature value and the preheating target temperature value are determined by the user according to the cooking mode, and the steam oven is determined according to the cooking mode.

[0070] S200. Temperature detection: detect the midpoint temperature value and the temperature values of multiple boundary...

Embodiment 2

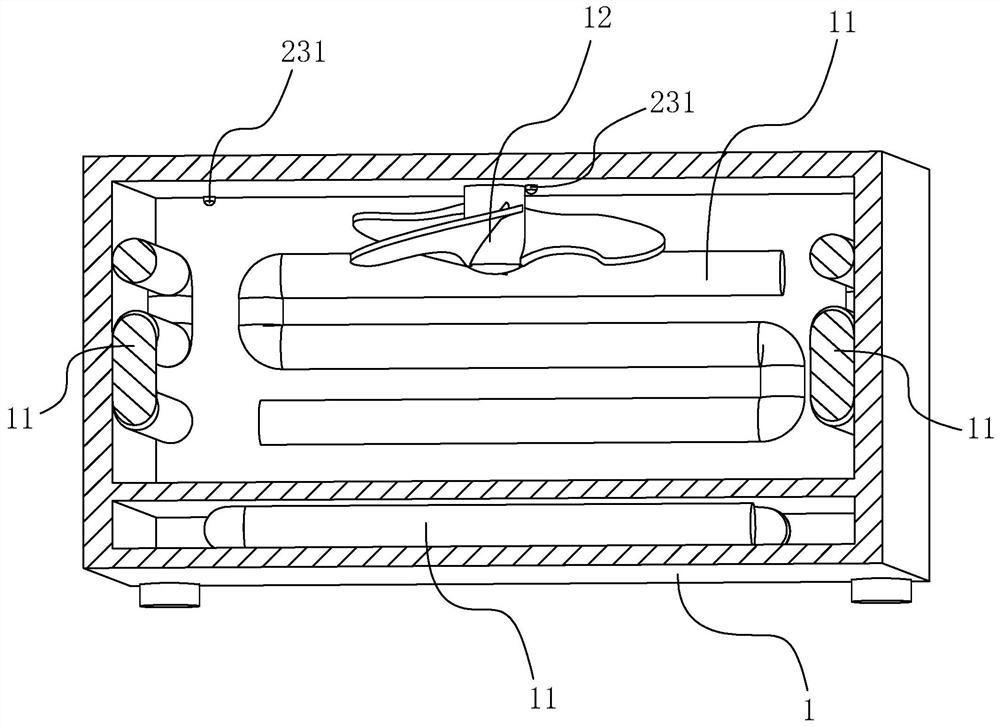

[0096] Embodiment 2. The present invention provides a multi-stage temperature field control system for a steam oven, such as figure 2 and image 3 As shown, it includes a steam oven casing 1 and a plurality of heating pipes 11 fixedly connected in the steam oven casing 1, and a stirring fan 12 is fixedly connected in the steam oven casing 1. Heating pipe 11 quantity is four, is positioned at the bottom, both sides and the back of oven casing 1 inside respectively.

[0097] Such as Figure 4 As shown, the steam oven box 1 is connected with a temperature control system 2, and the temperature control system 2 includes a storage module 21, a mode selection module 22, a temperature detection module 23, a temperature comparison module 24, a first preheating module 25, a second preheating module module 26 and cooking module 27.

[0098] Such as Figure 4 As shown, the storage module 21 receives the input information and stores it. The storage module 21 stores the PID algorithm ...

Embodiment 3

[0126] Embodiment 3. The present invention provides a storage medium for a multi-stage temperature field control method of a steam oven, including a memory storing a program of the above-mentioned multi-stage temperature field control method of a steam oven and a processor capable of executing the program stored in the memory .

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com