Rice conditioning process and instant rice production method

A technology of conditioning and processing, applied in food science, food ingredients containing oil, etc., can solve the problems of difficult industrial application of equipment, high cost, changing the structure of staple food, etc., to achieve good gloss, maintain the taste, and the effect of soft and tender taste.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0037] process such as figure 1 As shown, the specific method steps are as follows:

[0038] (1) Wash the rice quickly with drinking water and drain;

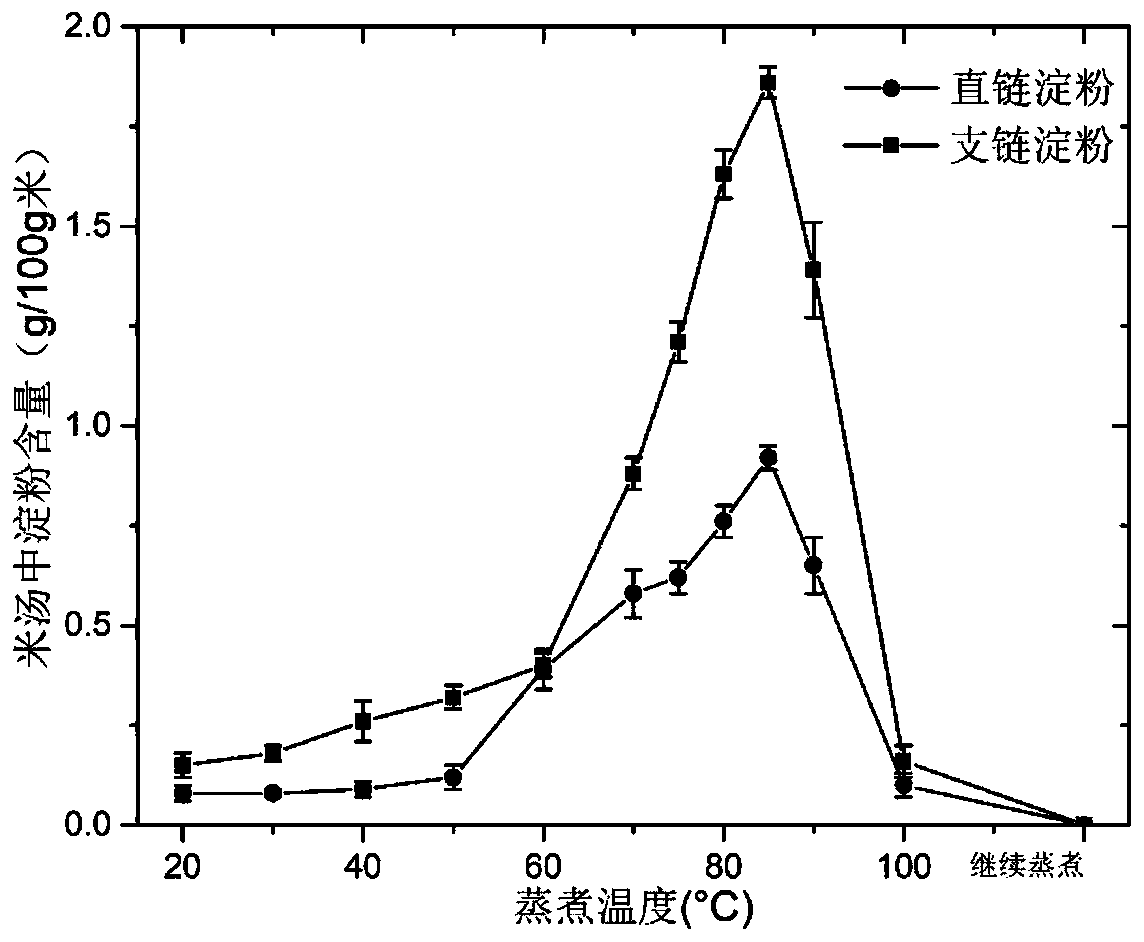

[0039] (2) Tempering: Instantaneous high-temperature fluidization pretreatment: transport the raw materials into the fluidization chamber, and fluidize them for 60 seconds at a fluidization temperature of 130°C; prepare a conditioning solution 1 containing soft rice flour, edible oil and water, wherein The mass ratio of soft ground rice, edible oil, water is 0.05:0.05:1.5, after using the miniature high-speed mixer to stir evenly, be 1:1.5 to soak rice 20min according to the mass ratio of the moisture content contained in rice and conditioning solution 1; Rice soup backfill process, by figure 2 It can be seen that when the cooking temperature is 90°C, the content of amylose and amylose in the rice soup is relatively high, and the cooking temperature range of the rice soup with a high content of extractables is taken as the s...

Embodiment 2

[0043] (1) Wash the rice quickly with drinking water and drain;

[0044] (2) Tempering: Instantaneous high-temperature fluidization pretreatment: transport the raw materials into the fluidization chamber, and fluidize them at a fluidization temperature of 160°C for 20s; prepare a conditioning solution 1 containing soft rice flour, edible oil and water, wherein The mass ratio of soft ground rice, edible oil, water is 0.1:0.03:2, after using the miniature high-speed mixer to stir evenly, according to the mass ratio of the moisture content contained in the rice and conditioning solution 1 is 1:2 to soak rice 15min; Pass Rice soup backfilling process, take 30% of the rice soup obtained when cooking to 85°C (the total amount of rice soup can be obtained by leaching, as a reference for subsequent production), and add it to the new system to replace part of the water, the ratio is the same as that of conditioning solution 1 , prepare the conditioning solution 2, and maintain the temp...

Embodiment 3

[0048] (1) Wash the rice quickly with drinking water and drain;

[0049] (2) Tempering: Instantaneous high-temperature fluidization pretreatment: transport the raw materials into the fluidization chamber, and fluidize them for 40 seconds at a fluidization temperature of 140°C; prepare a conditioning solution 1 containing soft rice flour, edible oil and water, wherein The mass ratio of soft rice flour, edible oil, and water is 0.08:0.04:1.8. After stirring evenly with a miniature high-speed mixer, soak the rice for 10 minutes according to the mass ratio of rice and water in conditioning solution 1 as 1:1.8; through the rice soup backfill process, take 25% of the rice soup obtained when cooking to 80°C (the total amount of rice soup can be obtained by leaching, which can be used as a reference for subsequent production), is added to the new system to replace part of the water, and the proportion is the same as that of the conditioning solution 1 to prepare the conditioning soluti...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - Generate Ideas

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com