Control method and device for water temperature of regulation part of cocoon cooking machine

A control method and cocoon cooking machine technology, which can be used in electric temperature control, mechanical treatment, textile and paper making, etc., and can solve the problems of increased roughness of 10,000 meters, increased dissolution of sericin, and many inner layers. , to achieve the effect of improving the quality index and level, improving the cooking quality and improving the unwinding rate

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

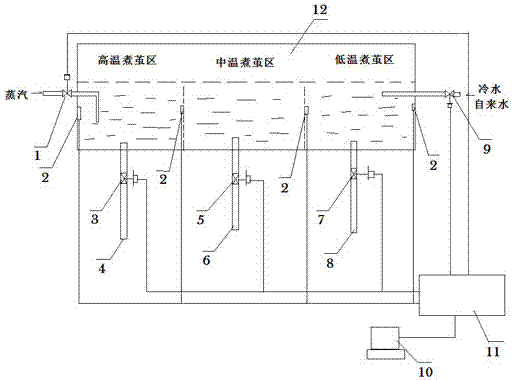

[0031] Use mulberry silkworms from a certain village in Xincheng County, Guangxi to reel silk, add 5 grams of sodium dodecylbenzenesulfonate and 10 grams of fatty alcohol polyoxyethylene ether per 100 kilograms of water in a circulating cocoon boiling tank, set the high temperature The water temperature in the zone is 65-80°C, the water temperature in the middle temperature zone is 55-65°C, the water temperature in the low temperature zone is 30-40°C, and the residence time is 12-18 minutes. Several temperature sensors are installed in the adjustment part of the silkworm cocoon circulation cocoon cooking machine, and the drain pipe control valves of the drain pipe 4 in the high temperature area, the drain pipe 6 in the middle temperature area and the drain pipe 8 in the low temperature area are precisely controlled by the electrical control method and the computer, and the temperature The temperature signal sent by the sensor is transmitted to the central controller, and then t...

Embodiment 2

[0033] Using silkworm cocoon ropes cultivated in Xincheng County, Guangxi, add 3 grams of sodium dodecylbenzenesulfonate and 12 grams of secondary alcohol polyoxyethylene ether for every 100 kilograms of water in the circulating cocoon cooking machine, and set the high temperature zone control The water temperature is 70-80°C, the water temperature is 55-65°C in the medium temperature zone, and 25-340°C in the low temperature zone, and the residence time is 12-18 minutes. Several temperature sensors are installed in the adjustment part of the silkworm cocoon circulation cocoon cooking machine, and the drain pipe control valves and temperature sensors of the drain pipe 4 in the high temperature area, the drain pipe 6 in the middle temperature area and the drain pipe 8 in the low temperature area are precisely controlled by electrical control mode and computer The temperature signal sent is transmitted to the central controller, and then the computer gives instructions to control...

Embodiment 3

[0035] Use the silkworm cocoon suisi cultured in Binyang County, Guangxi, add 2 grams of sodium dodecylbenzenesulfonate and 10 grams of alkylphenol polyoxyethylene ether per 100 kilograms of water in the adjustment part of the circulating cocoon cooking machine, and set the high temperature The water temperature in the zone is 70-80°C, the water temperature in the middle temperature zone is 55-65°C, the water temperature in the low temperature zone is 25-30°C, and the residence time is 12-18 minutes. Several temperature sensors are installed in the mulberry silkworm circulation cocoon boiling tank, and the drain pipe control valves of the drain pipe 4 in the high temperature area, the drain pipe 6 in the middle temperature area and the drain pipe 8 in the low temperature area are precisely controlled by the electrical control mode and the computer, and the temperature sensor sends The temperature signal is transmitted to the central controller, and then the computer gives instr...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com