Cooked beef and mutton product processing and feeding device and using method thereof

A technology for beef and mutton and cooked food, which is applied in the field of processing and feeding devices for beef and mutton cooked food products, can solve the problems of reducing the qualified rate of food products, reducing the efficiency of feeding and subsequent processing of meat food materials, increasing limitations and inconvenience, and achieving improvement Feeding and conveying efficiency, promotion of feeding and conveying efficiency, effect of improving sliding and guiding range

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

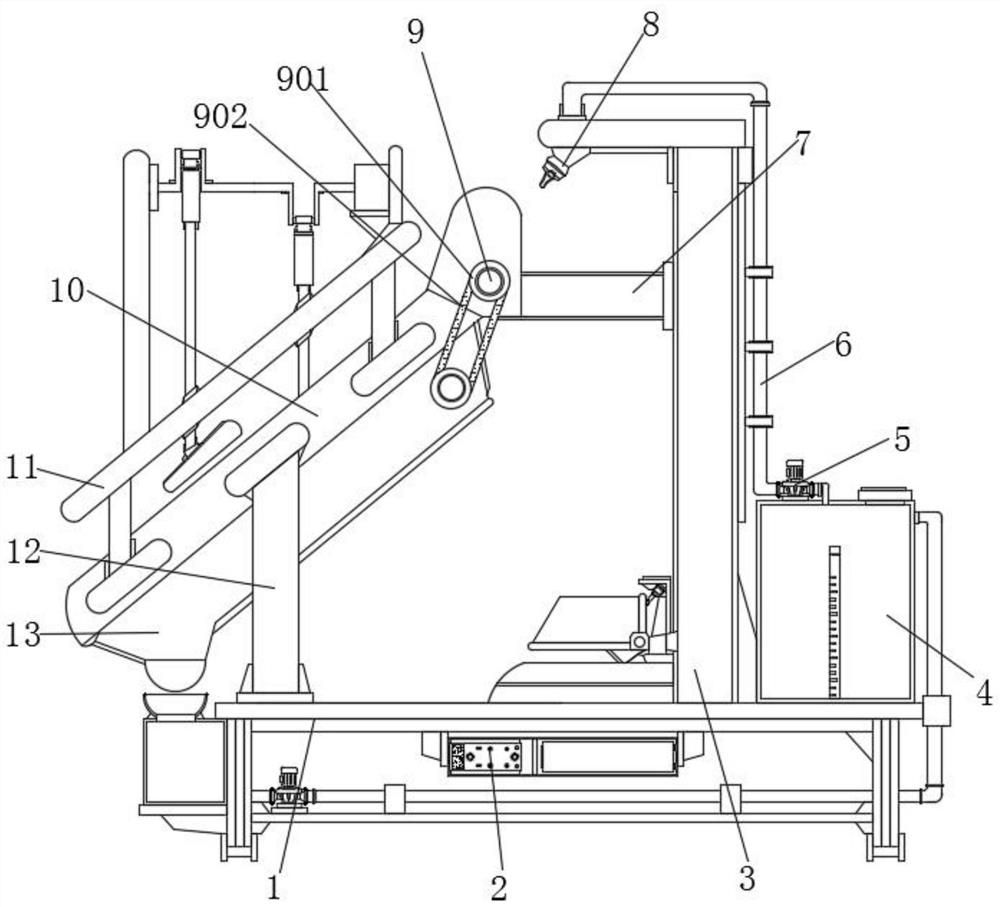

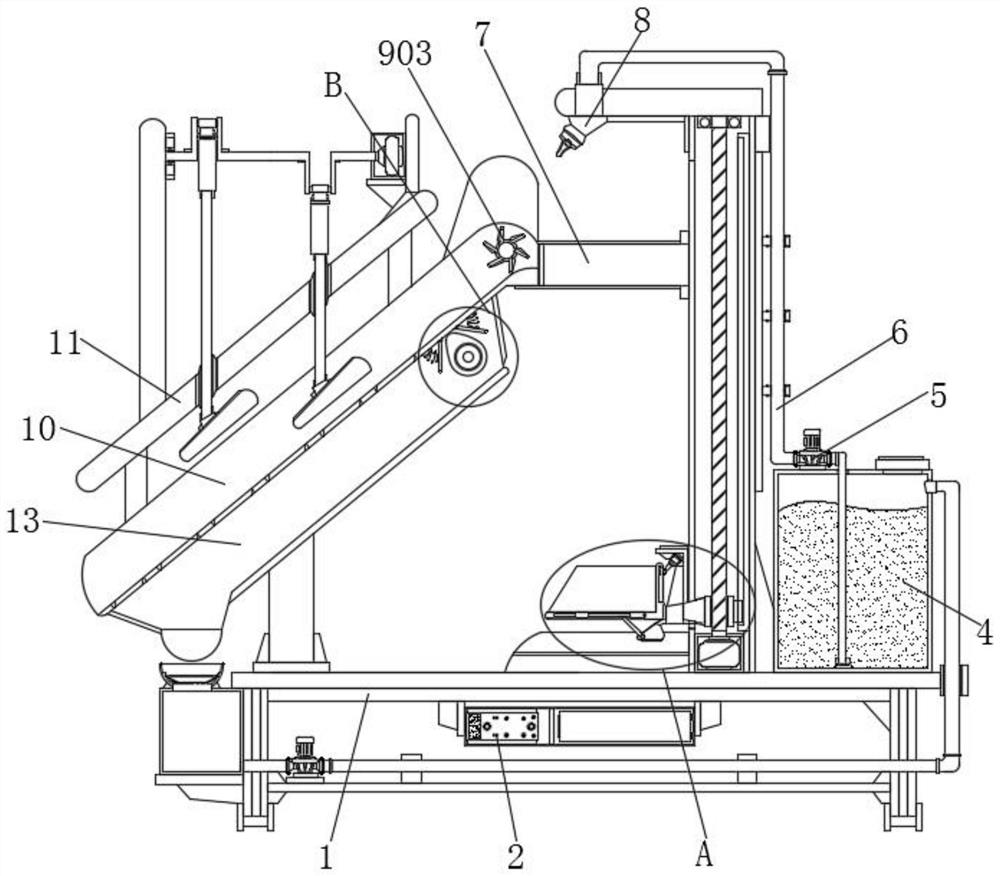

[0047] Example 1, such as Figure 1-2 As shown, when the blood of the water liquid and the meaty food infiltrates in the diversion groove 13 from the diversion hole 27, the water liquid is introduced into the diversion port by the oblique structure of the diversion groove 13, and enters the contact hole through the contact of the diversion port. During the liquid tank, the filter screen is used to filter the impurities in the blood water, so that the water liquid is collected in the liquid receiving tank, and then the backflow pump is started through the console 2, and the water liquid is introduced into the connecting pipe into the water storage tank 4 by the backflow pump. Water circulation and reuse can be formed to form a circulating water liquid spraying and thawing work. When the blood content in the water liquid is too high, the water liquid can be discharged through the drain port at the bottom of the diversion tank 13, and the water storage tank 4 can be replenished. ...

Embodiment 2

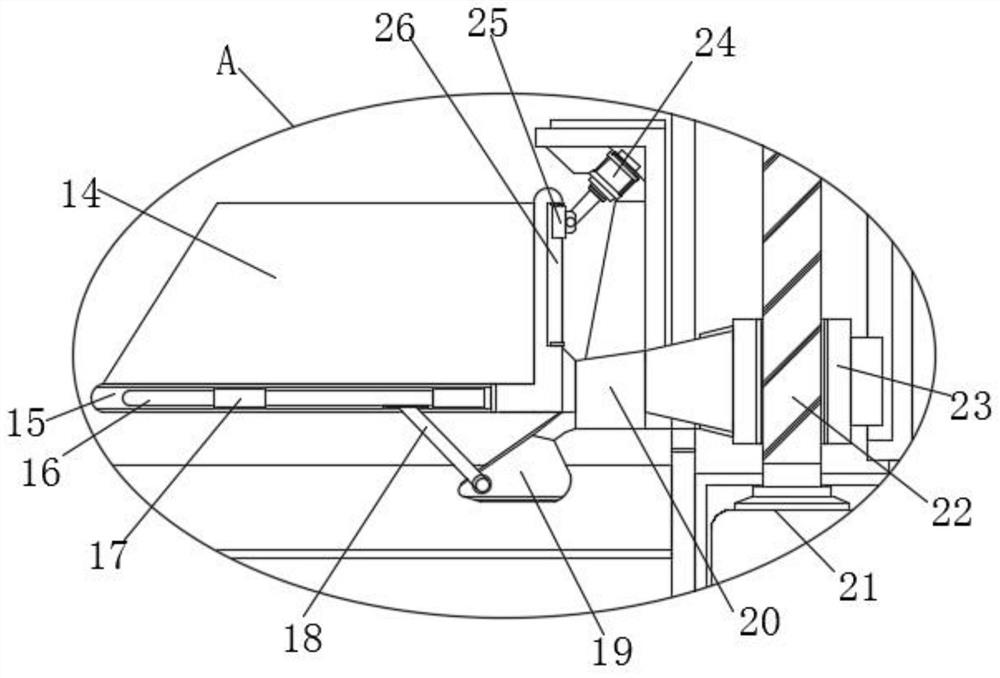

[0048] Example 2, such as Figure 6 As shown, when the food material is transported on the surface of the material guide table 10, the drive motor 114 can be started by the console 2, and the start of the drive motor 114 can be used to drive the rotating shaft 116 and two groups of U-shaped seats 115 to rotate. The rotation drives two sets of hinged rods 113 and movable rods 112 to form an intermittent up-and-down lift, and then the movable rods 112 drive the pressing plate 111 to intermittently squeeze the food material flowing on the surface of the material guide table 10, and the blood in the food material is sprayed and thawed in the water liquid Under the influence of extruding, improve the production quality of the subsequent cooked food processing of the food material, and further improve the thawing efficiency of the food material.

[0049] Working principle: When the device is in use, the high-pressure water pump 5, the servo motor 21 and the electric push rod 24 can ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com