Heat supply pipeline risk distribution analysis method and routing inspection path planning system

A technology of heating system and inspection path, applied in the field of risk distribution analysis method of heating pipeline and inspection path planning system, can solve the problems of limited inspection distance and working time, achieve accuracy and effectiveness, eliminate The effect of endurance anxiety and reducing workload

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

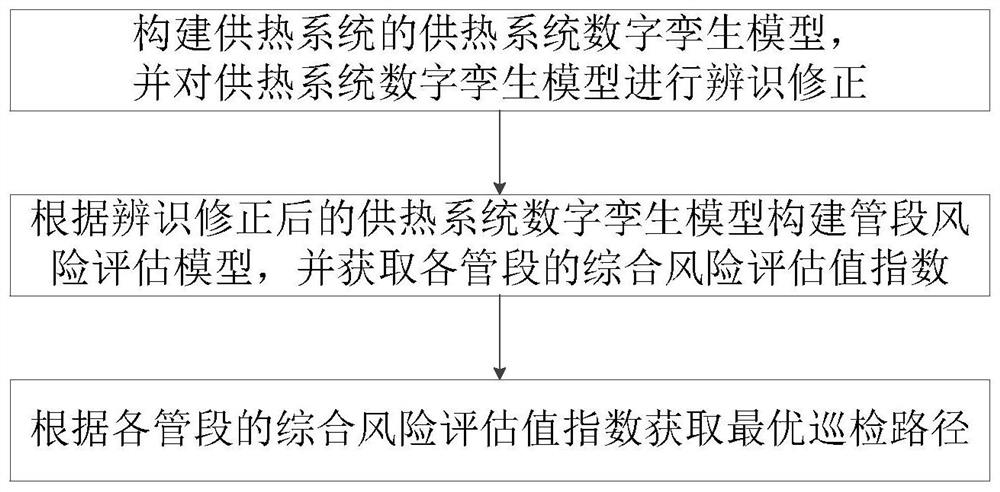

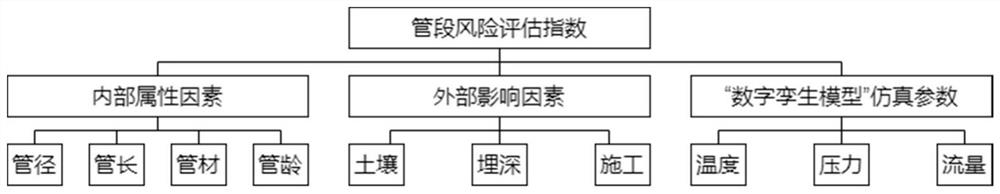

[0076] Such as figure 1 and figure 2 As shown, this embodiment 1 provides a thermal pipeline risk analysis and inspection route planning method based on the digital twin model, including: constructing the digital twin model of the heating system of the heating system, and performing a digital twin model on the digital twin model of the heating system Identification and correction; build a pipe section risk assessment model based on the identified and corrected digital twin model of the heating system, and generate the threshold of the comprehensive risk assessment index based on the basic data information database of the pipe section and the accumulated historical process data. Calculate and obtain the comprehensive risk assessment value index of each pipeline section based on the actual operation data, compare the comprehensive risk assessment value index with the threshold value; and use the genetic algorithm to obtain the optimal inspection path according to the comprehens...

Embodiment 2

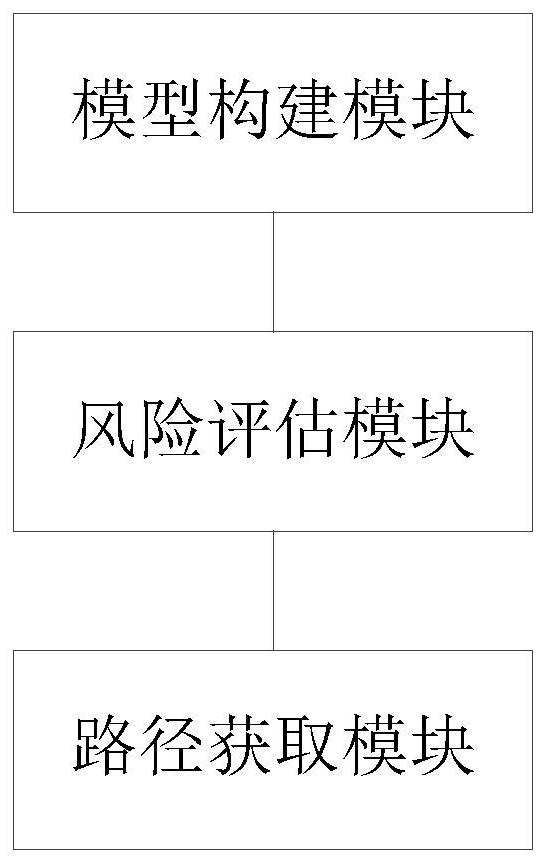

[0103] Such as image 3 As shown, on the basis of embodiment 1, this embodiment 2 also provides a thermal pipeline risk analysis and inspection path planning system based on the digital twin model, including: a model building block, constructing a heating system digital model of the heating system The twin model is used to identify and correct the digital twin model of the heating system; the risk assessment module builds a risk assessment model for the pipeline section based on the identified and corrected digital twin model of the heating system, and obtains the comprehensive risk assessment value index of each pipeline section; and obtains the path The module obtains the optimal inspection path according to the comprehensive risk assessment index of each pipe section.

[0104] In this embodiment, the specific functions of each module have been described in detail in Embodiment 1, and will not be repeated in this embodiment.

[0105] In this embodiment, each module may be i...

Embodiment 3

[0107] Such as Figure 4 As shown, on the basis of embodiment 1, this embodiment 3 also provides an inspection system, including: a server, the server is suitable for obtaining the optimal inspection path; inspection equipment, the inspection equipment is suitable for An optimal inspection path sent by the server is received, and the inspection device is adapted to perform an inspection operation of a risky pipe segment according to the optimal inspection path.

[0108] In this embodiment, the server is adapted to use the digital twin model-based thermal pipeline risk analysis and inspection path planning method in Embodiment 1 to obtain an optimal inspection path.

[0109] To sum up, the present invention builds a digital twin model of the heating system, and identifies and corrects the digital twin model of the heating system; constructs a risk assessment model for pipe sections based on the identified and corrected digital twin model of the heating system, and Obtain the c...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com