Weighted slickwater fracturing fluid and preparation method thereof

A water fracturing and slippery technology, which is applied in chemical instruments and methods, drilling compositions and other directions, can solve the problems of guar gum not easily dissolved, poor pump pressure reduction effect, poor wellbore liquid column pressure, etc. Viscosity and oil-water interfacial tension, reducing the length of diffusion path, good effect of reservoir stimulation

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0088] The weighted slick water fracturing fluid described in Example 1 consists of the following mass percentages:

[0089] 0.1% JHFR-2A drag reducer, 0.2% JHFD multifunctional additive, 0.5% HE~BIO biological oil displacement agent, 15%~30% calcium chloride, and the balance is water.

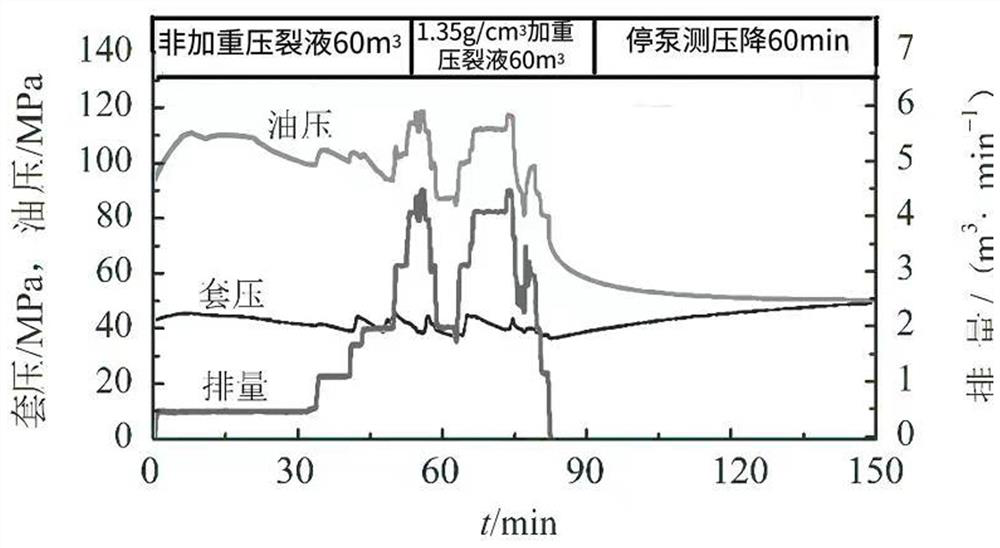

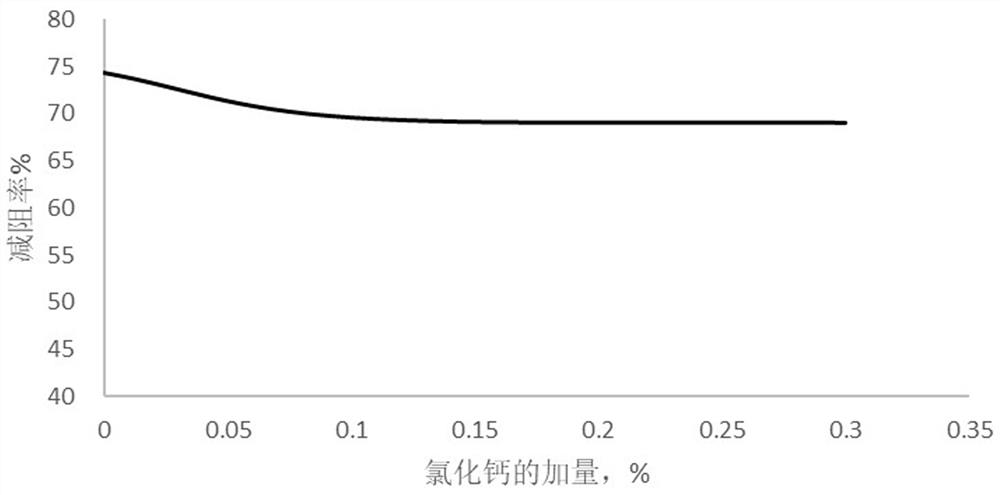

[0090] The weighted slickwater fracturing fluid system obtained in Example 1 was tested for drag reduction: the experimental instrument used was a high temperature and high pressure slickwater drag reduction tester, the test temperature was 25°C, the pipe diameter was 10mm, and the displacement was 30L / min. Determination of Example 1 aggravated the relationship between the drag reduction rate of the slick water fracturing fluid system and the concentration of calcium chloride, (see figure 2 ) figure 2 It is the relationship diagram between the amount of calcium chloride added and the drag reduction rate in the present invention, from which it can be seen that the drag reduction rate of the ...

Embodiment 2

[0092] The weighted slick water fracturing fluid described in Example 2 consists of the following mass percentages:

[0093] 0.1% JHFR-2D drag reducer, 0.2% JHFD multifunctional additive, 0.5% HE~BIO biological oil displacement agent, 15%~45% sodium formate, and the balance is water.

[0094] For the weighted slickwater fracturing fluid system obtained in Example 2, the surface tension, interfacial tension and anti-swelling ratio were tested respectively, and the test results are shown in Table 1. It can be seen from Table 1 that the weighted slickwater fracturing fluid system of Example 2 has lower surface tension, interfacial tension and higher anti-swelling performance.

[0095] Table 1 Performance test results of aggravated slickwater fracturing fluid

[0096]

Embodiment 3

[0098] The weighted slick water fracturing fluid described in Example 3 consists of the following mass percentages:

[0099] 0.05%~0.2% JHFR-2D drag reducer, 0.2% JHFD multifunctional additive, 0.5% HE~BIO biological oil displacement agent, 20% sodium nitrate, and the balance is water.

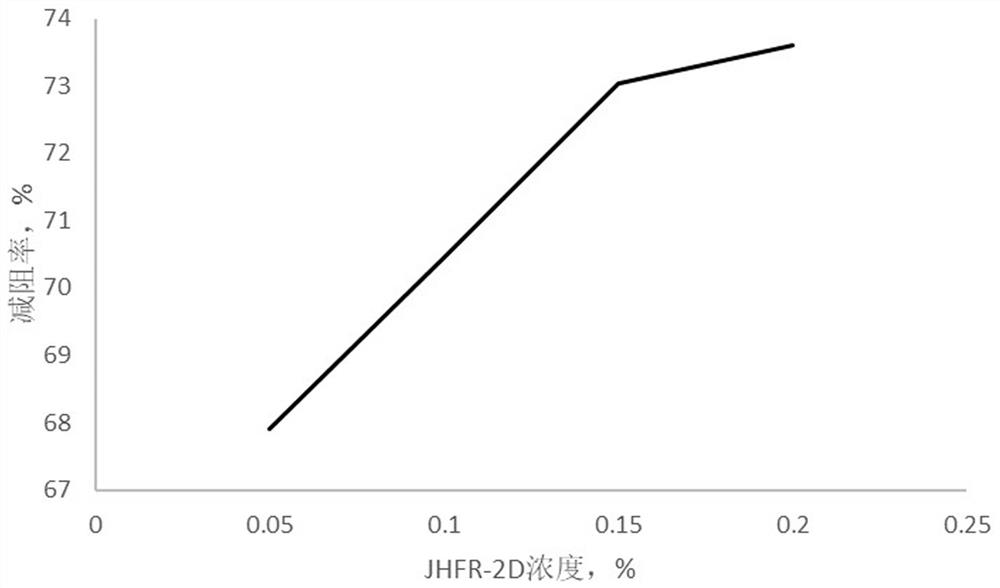

[0100] The drag reduction rate test of the weighted slick water fracturing fluid system obtained in Example 3 was carried out. The experimental instrument was a high temperature and high pressure slick water drag reduction rate tester. The test temperature was 25 °C, the pipe diameter was 10 mm, and the displacement was 30 L / min; Determination of the drag reduction ratio of the weighted slick water fracturing fluid system of Example 3 along with the change relationship of the JHFR-2D drag reducer concentration (see image 3 ),From image 3 It can be seen that the drag reduction rate of the weighted slickwater fracturing fluid increases with the increase of the JHFR-2D drag reducer concentrati...

PUM

| Property | Measurement | Unit |

|---|---|---|

| density | aaaaa | aaaaa |

| surface tension | aaaaa | aaaaa |

| interfacial tension | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com