An energy-saving fluidized bed jet mill

A jet mill and fluidized bed technology, applied in the field of fluidized bed jet mill equipment, can solve the problems of low pulverization efficiency, narrow pulverization area, and high equipment energy consumption, so as to improve pulverization efficiency, reduce state space, improve The effect of the smashing effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment

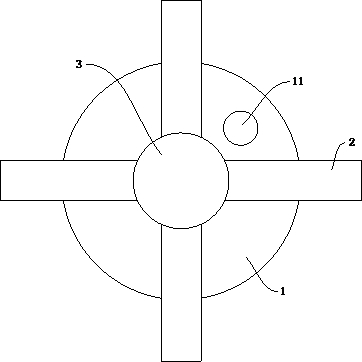

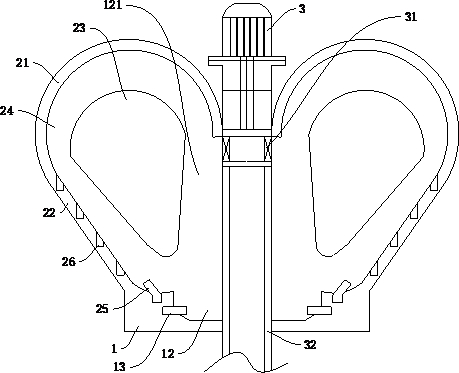

[0030] like figure 1 , as shown in 2, an energy-saving fluidized bed jet mill, comprising a base 1 and a number of circulating lobes 2 distributed on the base 1 in a circular array with the axis of the base 1 as the axis of rotation. Specifically, in this embodiment, Set as 4 circulating flaps 2, the purpose of multiple crushing is achieved by the cooperation of the circulating flaps 2 and the base 1, and a diversion channel 24 is constructed at the same time to improve the crushing efficiency; the specific structure is as follows:

[0031] The base 1 is a rotating body; the interior of the base 1 is provided with a first crushing cavity 12, and the first crushing cavity 12 is also a rotating body; the base 1 is provided with a feeder 11; Energy-saving fluidized bed jet mill can be used,

[0032] The circulating valve 2 has a half-heart-shaped structure; the inside of the circulating valve 2 is provided with a second pulverizing cavity 121; the first pulverizing cavity 12 and...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com