Fuel cell membrane electrode, membrane electrode preparation method, fuel cell system and vehicle

A fuel cell membrane and electrode technology, which is applied in the fields of vehicles, fuel cell systems, and fuel cell membrane electrodes, and can solve problems such as detachment of gas diffusion layer plates or catalyst layers

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0057] A fuel cell is a chemical device that directly converts the chemical energy of fuel into electrical energy, also known as an electrochemical generator. Fuel cells are the fourth power generation technology after hydropower, thermal power and atomic power. Since the fuel cell converts the Gibbs free energy in the chemical energy of the fuel into electrical energy through an electrochemical reaction, it will not be limited by the Carnot cycle effect, so the efficiency is high, and the fuel cell uses fuel and oxygen as raw materials. There are no mechanical transmission parts, very little harmful gas is discharged, and the service life is long. The fuel cell membrane electrode 100 is a membrane electrode assembly, also known as a membrane electrode, which can be understood as an electrode equipped with a membrane combination in its structure, and is a key core component of fuel cell power generation.

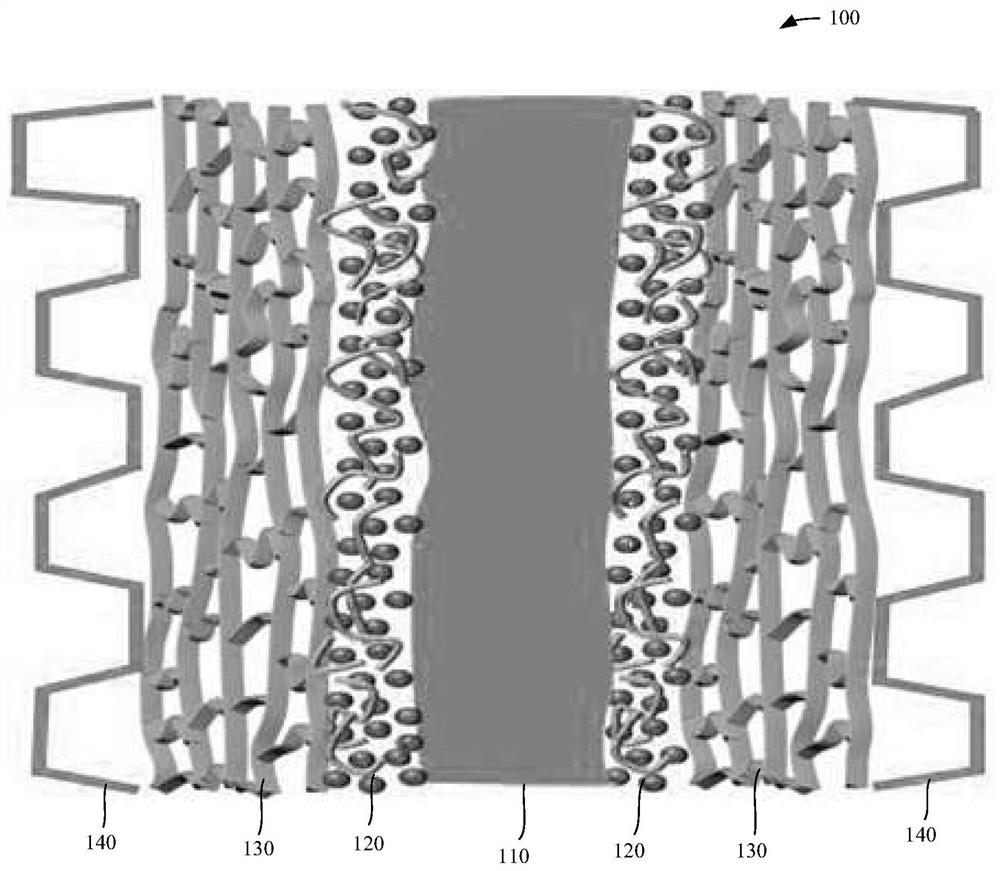

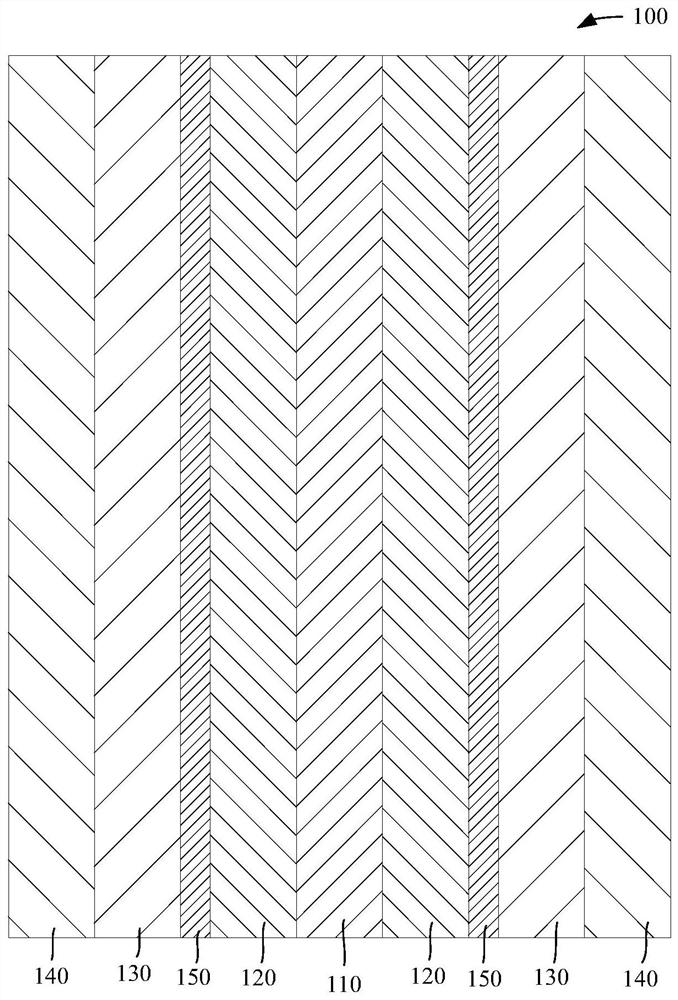

[0058] like figure 2 and image 3 As shown, a fuel cell membrane el...

Embodiment 2

[0065] The fuel cell membrane electrode 100 also includes a proton exchange membrane 110 . Specifically, the proton exchange membrane 110 (PEM) provides channels for the migration and transport of protons, not only has the function of blocking, but also has the function of conducting protons. The protons pass through the proton exchange membrane 110 from the anode to the cathode, and form a loop with the electron transfer of the external circuit to provide current to the outside world. Therefore, the performance of the proton exchange membrane 110 plays a very important role in the performance of the fuel cell membrane electrode 100, directly affecting battery life. The material of the proton exchange membrane 110 meets the following conditions: good proton conductivity; the electroosmosis of water molecules in the membrane is small; the permeability of gas in the membrane is as small as possible; the electrochemical stability is good; the dry-wet conversion performance is goo...

Embodiment 3

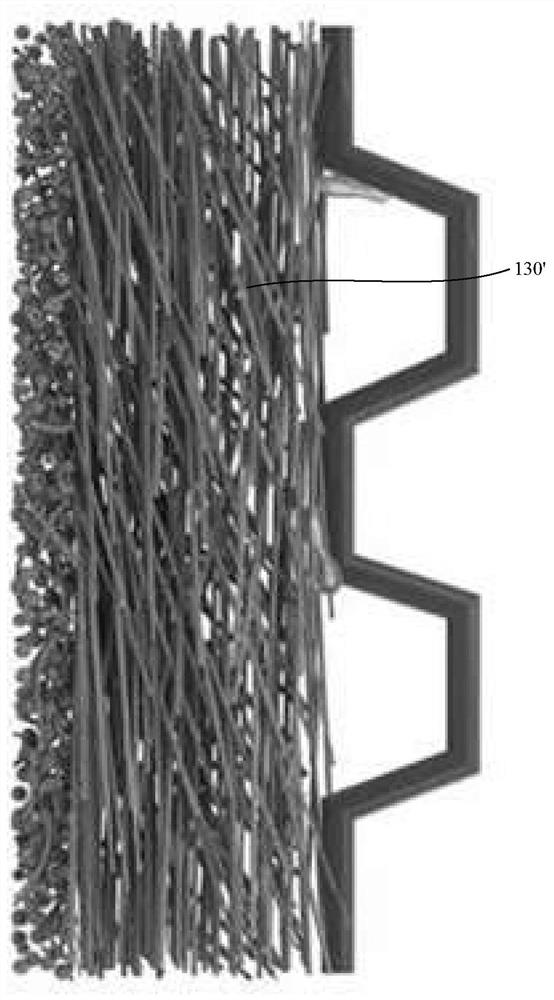

[0067] The gas diffusion layer 130 is an elastic carbon nanotube porous membrane. By providing the gas diffusion layer 130 as an elastic carbon nanotube porous membrane, the gas diffusion layer 130 has a uniform porous thin layer structure and has excellent stretchability, electrical conductivity, chemical stability, and thermal stability. In addition, carbon nanotubes are nanomaterials, which also have advantages such as light weight.

[0068] In another embodiment, the gas diffusion layer 130 is an elastic graphene porous membrane. By providing the gas diffusion layer 130 as an elastic graphene porous membrane, the gas diffusion layer 130 has a uniform porous thin layer structure and has excellent stretchability, electrical conductivity, chemical stability, and thermal stability. In addition, graphene is a sp 2 A material in which hybridized carbon atoms are tightly packed into a single-layer two-dimensional honeycomb lattice structure has more excellent electrical and mec...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com