Schottky diode based on non-polar GaN and preparation method thereof

A Schottky diode, non-polar technology, applied in the field of microelectronics, can solve the problems affecting device performance, reducing the density and mobility of two-dimensional electron gas 2DEG, current leakage, etc., to improve device performance and high area utilization efficiency , the effect of large reverse breakdown voltage

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

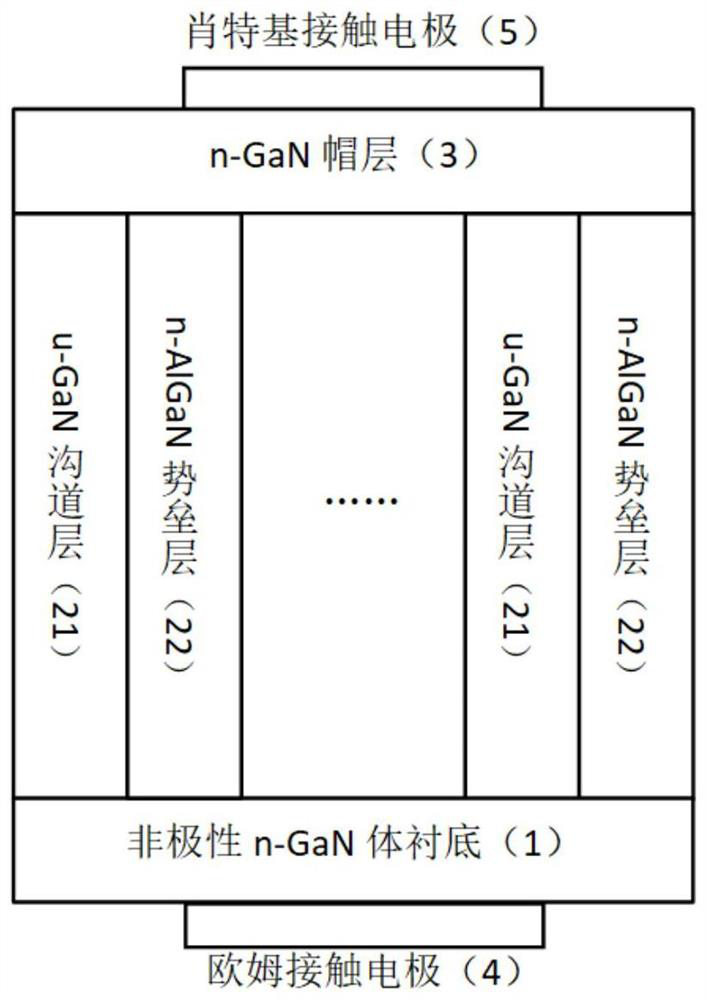

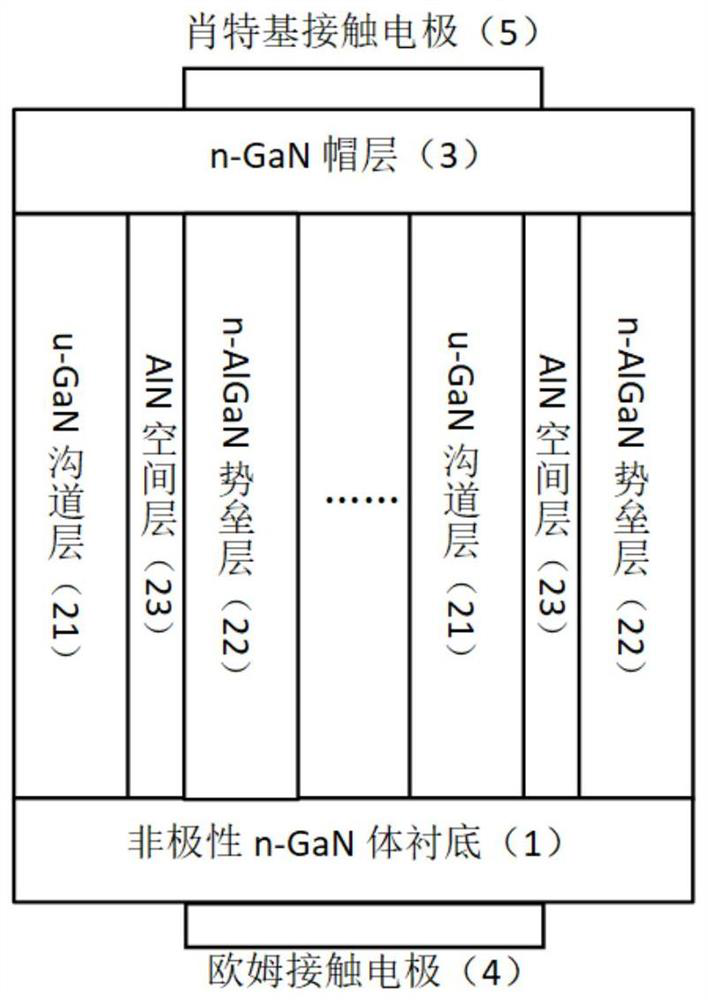

[0035] See figure 1 , figure 1 It is a schematic structural diagram of a non-polar GaN-based Schottky diode provided by an embodiment of the present invention, which includes:

[0036] GaN substrate 1, the vertical multi-channel layer 2 on the GaN substrate 1, the GaN cap layer 3 on the vertical multi-channel layer 2, the ohmic contact electrode 4 on the back side of the GaN substrate 1, and the GaN cap layer Schottky contact electrode 5 on 3; where,

[0037] The GaN substrate 1 is a non-polar n-type GaN bulk substrate;

[0038] The vertical multi-channel layer 2 includes several u-GaN channel layers 21 and n-AlGaN barrier layers 22, and the u-GaN channel layers 21 and n-AlGaN barrier layers 22 are arranged at intervals along the horizontal direction to form a Parallel multi-channel structure of substrate 1.

[0039] Since this embodiment uses a bulk material with higher crystal quality as the substrate, the quality of the device is improved.

[0040] Further, all u-GaN c...

Embodiment 2

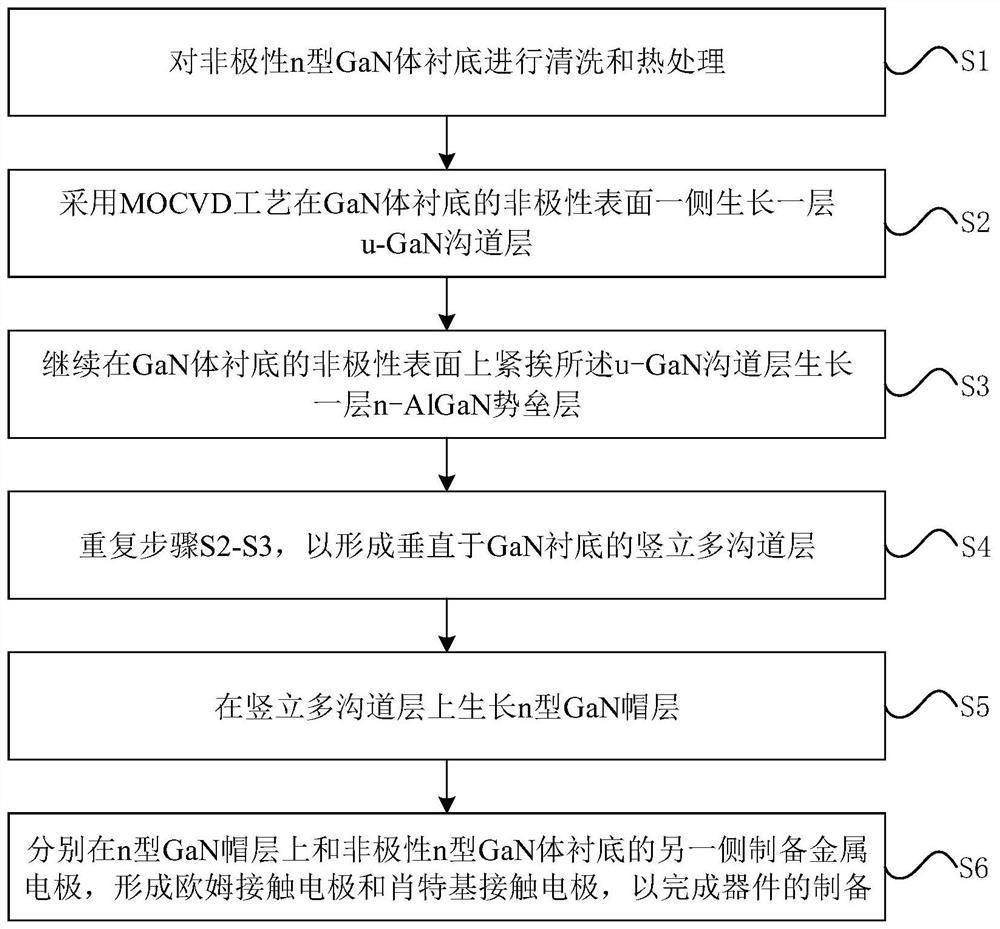

[0055] On the basis of the foregoing first embodiment, this embodiment provides a method for fabricating a non-polar GaN-based Schottky diode. See image 3 , image 3 It is a schematic flowchart of a method for preparing a non-polar GaN-based Schottky diode provided in an embodiment of the present invention, which includes:

[0056] S1: cleaning and heat-treating the non-polar n-type GaN bulk substrate;

[0057] S2: A u-GaN channel layer is grown on the non-polar surface side of the GaN bulk substrate by MOCVD process;

[0058] S3: Continue to grow an n-AlGaN barrier layer on the non-polar surface of the GaN bulk substrate next to the u-GaN channel layer;

[0059] S4: Steps S2-S3 are repeated to form a vertical multi-channel layer perpendicular to the GaN substrate;

[0060] S5: growing an n-type GaN cap layer on the erected multi-channel layer;

[0061] S6: respectively preparing metal electrodes on the n-type GaN cap layer and the other side of the non-polar n-type GaN ...

Embodiment 3

[0094] The following describes the detailed process parameter setting of the present invention by taking the preparation of a non-polar Schottky diode with an Al composition of 20% in the n-AlGaN barrier layer as an example.

[0095] Step 1, cleaning and heat treatment of the substrate:

[0096] 1a) After cleaning the non-polar n-type GaN bulk substrate, put it into the reaction chamber of the metal organic chemical vapor deposition equipment MOCVD, and adjust the vacuum degree of the reaction chamber to be less than 2×10-2 Torr.

[0097] 1b) Pour hydrogen into the reaction chamber, and when the pressure in the reaction chamber rises to 30 Torr, heat the substrate to 1100° C. to complete the heat treatment of the substrate.

[0098] Step 2, using MOCVD process to perform vertical AlGaN / GaN multi-channel growth on the non-polar n-type GaN bulk substrate, the steps are as follows:

[0099] 2a) Mask the non-polar n-type GaN bulk substrate using a masking process, leaving the reg...

PUM

| Property | Measurement | Unit |

|---|---|---|

| thickness | aaaaa | aaaaa |

| thickness | aaaaa | aaaaa |

| thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com