Fabricated building overall upside-down construction system and construction method

A construction method and assembly technology, which is applied in the direction of construction, building structure, and building material processing, can solve problems such as deformation and lack of effective support for modules, achieve flexible settings, facilitate safe and civilized construction, and improve assembly accuracy Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

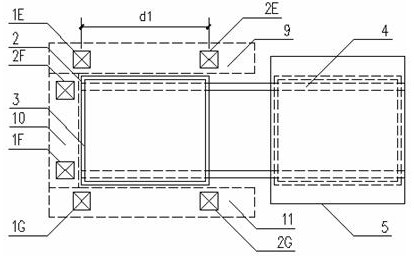

[0060] Embodiment 1: A whole flip-chip construction system for prefabricated buildings, such as Figure 8 As shown, including: independent column setting E area 9, independent column setting F area 10, independent column setting G area 11, tray 2, slideway 4, on-site standard floor assembly area 5, lifting device 6, lifting platform 7, steel strand Wire or steel tie rod 8; set two independent columns in the E area 9 of the independent column, that is, the first independent column 1E in the E area and the second independent column 2E in the E area, and set two independent columns in the F area 10 , that is, the first independent column 1F in the F area and the second independent column 2F in the F area, set up two independent columns in the G area 11 in the independent column, that is, the first independent column 1G in the G area and the second independent column in the G area 2G structure. Two independent columns are set in each independent column setting area to enclose the...

Embodiment 2

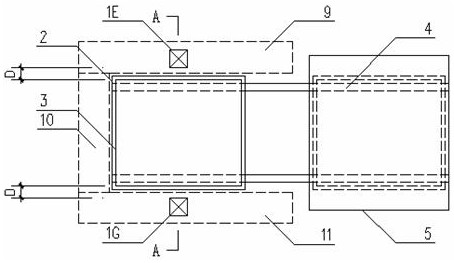

[0061] Embodiment 2: A whole flip-chip construction system for prefabricated buildings, such as Figure 9 As shown, including: independent column setting E area 9, independent column setting F area 10, independent column setting G area 11, tray 2, slideway 4, on-site standard floor assembly area 5, lifting device 6, lifting platform 7, steel strand Wire or steel tie rod 8; set two independent columns in the E area 9 of the independent column, that is, the first independent column 1E in the E area and the second independent column 2E in the E area, and set two independent columns in the F area 10 , that is, the first independent column 1F in the F area and the second independent column 2F in the F area, set up two independent columns in the G area 11 in the independent column, that is, the first independent column 1G in the G area and the second independent column in the G area 2G structure. In each independent column setting area, two independent columns are set to enclose th...

Embodiment 3

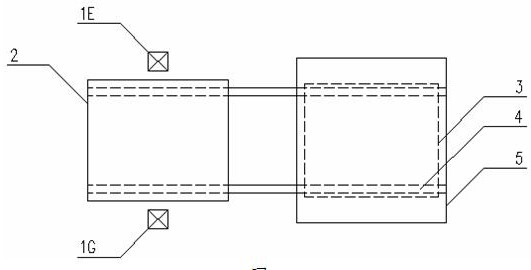

[0062] Embodiment 3: A whole flip-chip construction system of a prefabricated building, such as Figure 10 As shown, including: independent column setting E area 9, independent column setting F area 10, independent column setting G area 11, tray 2, slideway 4, on-site standard floor assembly area 5, lifting device 6, lifting platform 7, steel strand Wire or steel tie rod 8; three independent columns are set in the independent column setting area E 9, namely the first independent column 1E in the E area, the second independent column 2E in the E area and the third independent column 3E in the E area. Three independent columns are set up in F area 10, namely the first independent column 1F in F area, the second independent column 2F in F area and the third independent column 3F in F area, and three independent columns are set in area G in area 11, namely G The structure of the first independent column 1G in the area G, the second independent column 2G in the G area and the third...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com