Construction method for high-pier large-span bridge steel mixing beam in mountainous area

A technology of steel-concrete composite beams and construction methods, which is applied in the direction of bridges, bridge construction, erection/assembly of bridges, etc., and can solve the problems of extremely high requirements for installation and positioning accuracy and elevation accuracy, difficulty in guaranteeing construction quality and project progress, and the weight of bridge erecting machines. Large size and other problems, to improve the overall erection efficiency, improve the quality of assembly, and save labor

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0029] The method of the present invention will be described below through a specific embodiment.

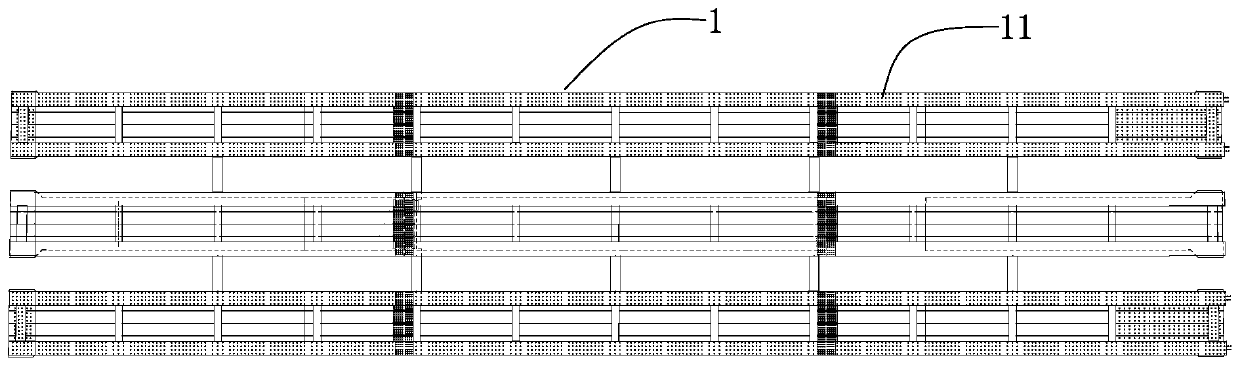

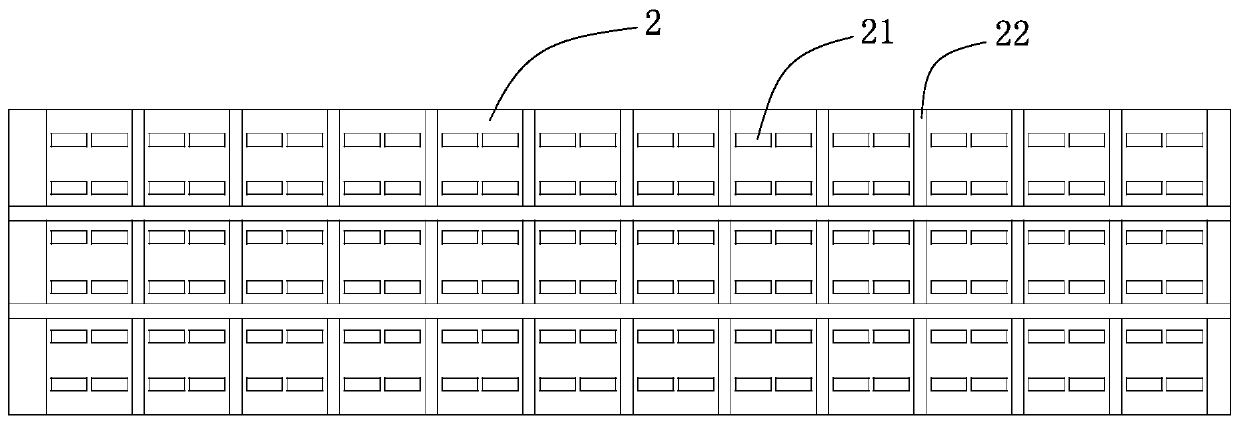

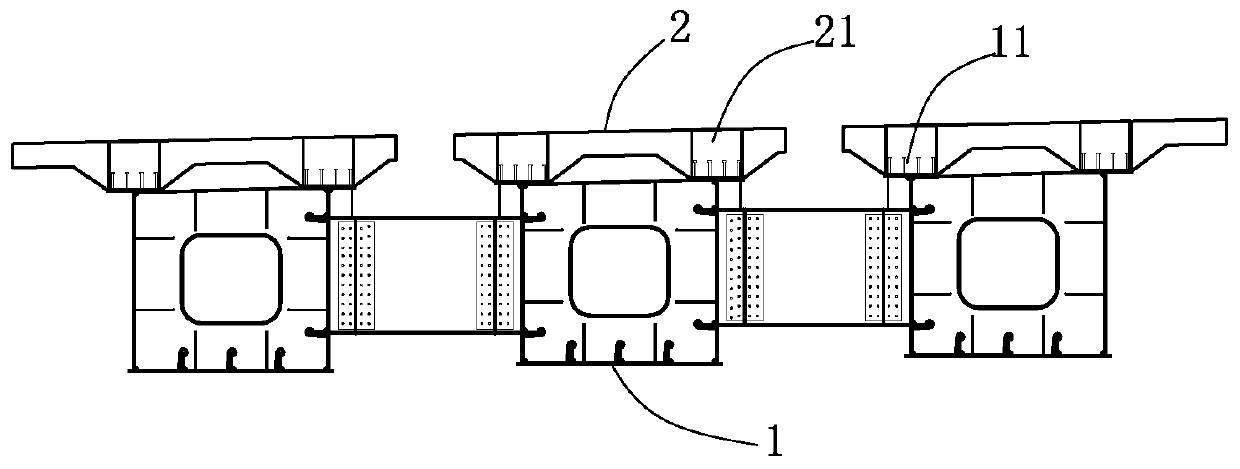

[0030] The Laiqu section of the Taihang Mountain Expressway constructed by the applicant spans the Rongwu existing expressway, with a maximum span of 50m. The design adopts a transverse three-box steel-concrete composite beam structure. Since the ground support cannot be erected in the mountainous area, it is planned to use a bridge erecting machine for construction. The steel girder part of the steel-concrete composite beam is a steel box with straight web openings, which are connected to form a three-box structure by connecting girders between boxes, and shear studs are set on the top to effectively connect with the bridge deck. The bridge decks form the overall deck with longitudinal wet joints. In order to ensure that the steel-concrete composite girders will not deflect too much due to the insufficient age of the bridge deck concrete after the steel-concrete composite gird...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com