Construction method for prefabricated box girder support in complex city environment

A construction method and box girder technology, applied in the direction of bridges, bridge construction, erection/assembly of bridges, etc., can solve the problems of harsh working environment, weld corrosion, plate cracking, etc., to improve efficiency, save costs, and ensure safety. Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0097] S1, measurement and setting out;

[0098] S11. Check the elevation and plane position of the supporting structure

[0099] Before erecting and installing the box girder, use instruments to check the elevation and plane position of the supporting structure. When checking, draw the mounting axis and end line on the supporting structure so that the box girder can be positioned accurately.

[0100] S12, pay-off and control position

[0101] According to the actual line centerline and pier center mileage released, the longitudinal centerline of each hole beam, the vertical and horizontal centerline of the support, the horizontal line of the plate end position and the contour line of the bottom of the support are released on the pier abutment surface, and the horizontal line of the plate end position Set out the bottom edge point of each box girder.

[0102] S2. Laying track and assembling bridge erecting machine;

[0103] S21. Selection of bridge erecting machine assembly...

Embodiment 2

[0158] Erection of ramp box girder

[0159] Since the ramp bridge deck is narrow and the longitudinal slope exceeds the design capability of the bridge erecting machine (the longitudinal slope does not exceed 3% slope ratio), necessary technical measures must be taken to erect the ramp box girder to ensure the safety of the erection.

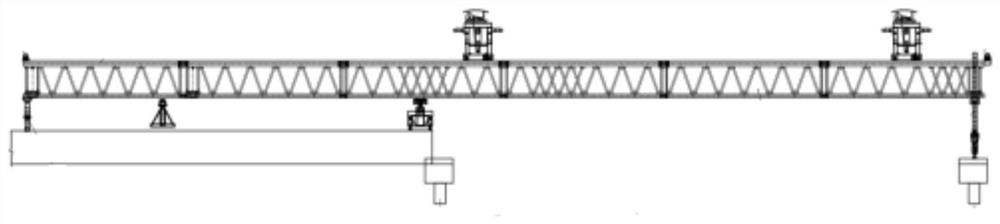

[0160] (1) Transformation of the bridge erecting machine

[0161] In order to adapt to the longitudinal slope with a slope ratio of 5.5%, it is necessary to modify the length of the front, middle and rear outriggers and the rear support of the bridge erecting machine to keep the bridge erecting machine in a stable posture parallel to the ground during erection. Considering that the rear of the bridge erecting machine is the main body of the load, adjusting the rear has little influence on the stability of the bridge erecting machine.

[0162] Therefore, the modification of the bridge erecting machine mainly adopts to increase the length of the mi...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com