A weather-resistant powder coating

A powder coating and weather resistance technology, applied in powder coatings, polyester coatings, epoxy resin coatings, etc., can solve the problems of poor salt spray resistance, easy aging, poor weather resistance of powder coatings, etc., to improve outdoor weather resistance. performance effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

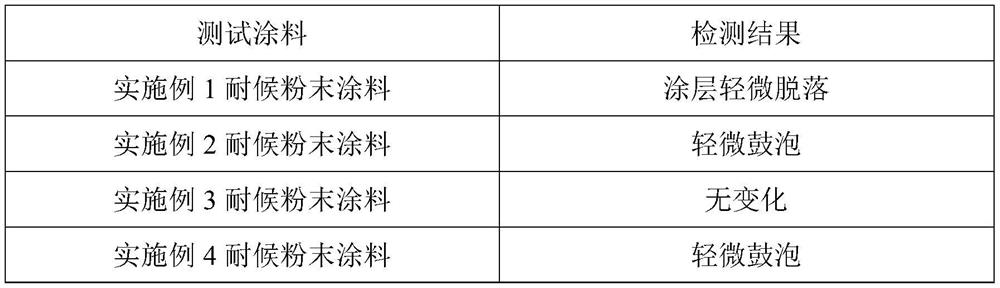

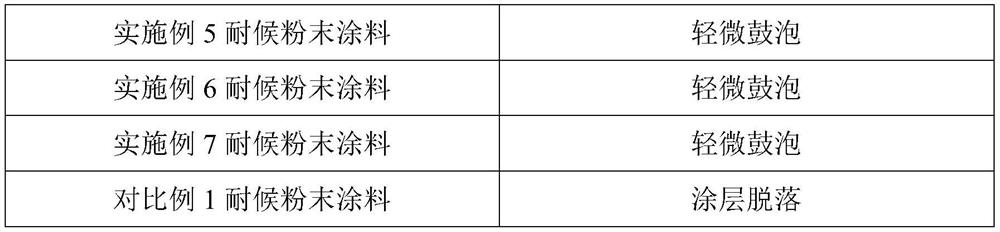

Examples

Embodiment 1

[0029] Example 1 Preparation of Weather Resistant Powder Coatings

[0030] Composition of raw materials in parts by weight: 40 parts of epoxy resin; 20 parts of polyester resin; 15 parts of filler (precipitated barium sulfate); 3 parts of curing agent (adipic acid dihydrazide); 2 parts of leveling agent (leveling agent PV88) ; 20 parts of weather-resistant composition;

[0031] The weather-resistant composition is composed of light stabilizer, antioxidant and titanium dioxide in a weight ratio of 2:3:30;

[0032] The light stabilizer is bis(2,2',6,6'-tetramethylpiperidinyl) sebacate; the antioxidant is pentaerythritol distearyl phosphite;

[0033] Preparation method of weather-resistant powder coating: put epoxy resin, polyester resin, filler, curing agent, leveling agent and weather-resistant composition into a high-speed mixer and mix evenly, then extrude the masterbatch with an extruder, and then mix The weather-resistant powder coating is obtained by crushing the master ...

Embodiment 2

[0034] Example 2 Preparation of Weather Resistant Powder Coatings

[0035] The parts by weight of raw materials are composed: the same as in Example 1;

[0036] The weather-resistant composition is composed of a light stabilizer, an antioxidant and a modified titanium dioxide in a weight ratio of 2:3:30;

[0037] Described light stabilizer, antioxidant are with embodiment 1;

[0038] Described modified titanium dioxide is prepared by the following method:

[0039] (1) Mixing titanium dioxide and polydimethylsiloxane (500 viscosity) uniformly to obtain a mixture; wherein, the weight ratio of titanium dioxide and polydimethylsiloxane is 1:1.5;

[0040] (2) calcining the mixture under the condition that the volume content of oxygen is 35% for 2 hours to obtain a solid; and then grinding the obtained solid product uniformly to obtain the modified titanium dioxide.

[0041] Preparation method of weather-resistant powder coating: the same as Example 1.

[0042] The difference be...

Embodiment 3

[0043] Example 3 Preparation of Weather Resistant Powder Coatings

[0044] The parts by weight of raw materials are composed: the same as in Example 1;

[0045] The weather-resistant composition is composed of a light stabilizer, an antioxidant, a dispersant and a modified titanium dioxide in a weight ratio of 2:3:2:30;

[0046] Described light stabilizer, antioxidant are with embodiment 1;

[0047] The dispersant is composed of microcrystalline paraffin and calcium stearate in a weight ratio of 2:1.

[0048] Described modified titanium dioxide is prepared by the following method:

[0049] (1) Mixing titanium dioxide and polydimethylsiloxane (500 viscosity) uniformly to obtain a mixture; wherein, the weight ratio of titanium dioxide and polydimethylsiloxane is 1:1.5;

[0050] (2) calcining the mixture under the condition that the volume content of oxygen is 35% for 2 hours to obtain a solid; and then grinding the obtained solid product uniformly to obtain the modified titan...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com