A kind of wide width and high weather resistance light conversion shed film and preparation method thereof

A technology of weather resistance and shed film, which is applied in the field of agricultural film, can solve the problems of high brittleness of the surface of shed film, poor foam stabilization performance of nylon, and unreasonable coordination, so as to achieve enhanced outdoor weather resistance, good foam stabilization performance and easy promotion Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0059] The expanded width of the five-layer co-extruded wide-width and high weather-resistant light-transforming shed film provided in this example is 16m, and the raw materials used are:

[0060]

[0061]

[0062] The film production parameters provided by the present embodiment are as follows:

[0063]

Embodiment 2

[0065] The expanded width of the five-layer co-extruded wide-width and high weather-resistant light-transforming shed film provided in this example is 16m, and the raw materials used are:

[0066]

[0067] The film production parameters provided by the present embodiment are as follows:

[0068]

Embodiment 3

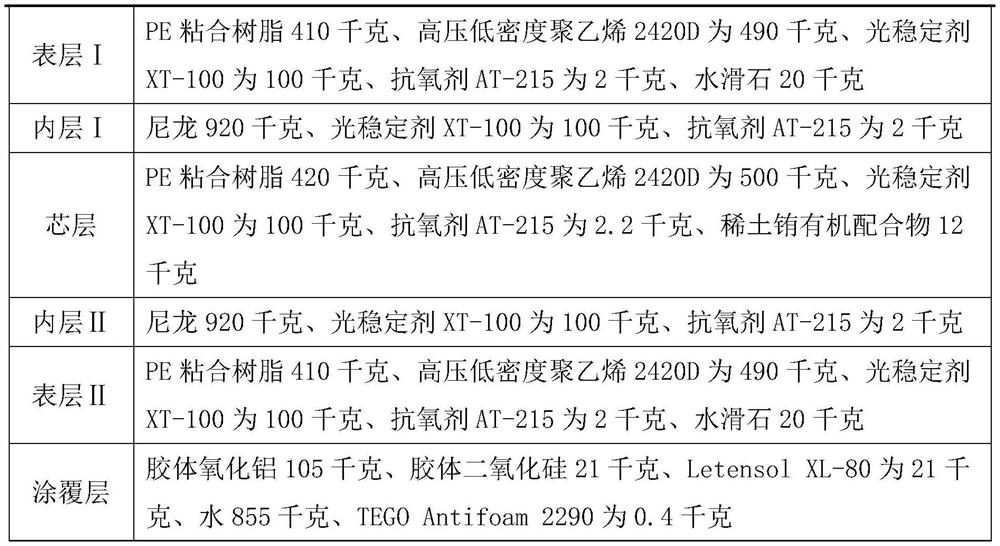

[0070] The unfolded width of the seven-layer co-extruded wide-width and high weather resistance light-transforming shed film provided in this example is 17m, and the raw materials used are:

[0071]

[0072] The film production parameters provided by the present embodiment are as follows:

[0073]

[0074]

PUM

| Property | Measurement | Unit |

|---|---|---|

| thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com