Silane self-crosslinking low-smoke halogen-free flame-retardant polyolefin oil-resistant elastomer material, and preparation method and application thereof

A self-crosslinking, polyolefin technology, used in insulators, rubber insulators, plastic/resin/wax insulators, etc., can solve problems such as equipment space reduction, and achieve the effect of enhancing internal friction and improving oil resistance

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1-4

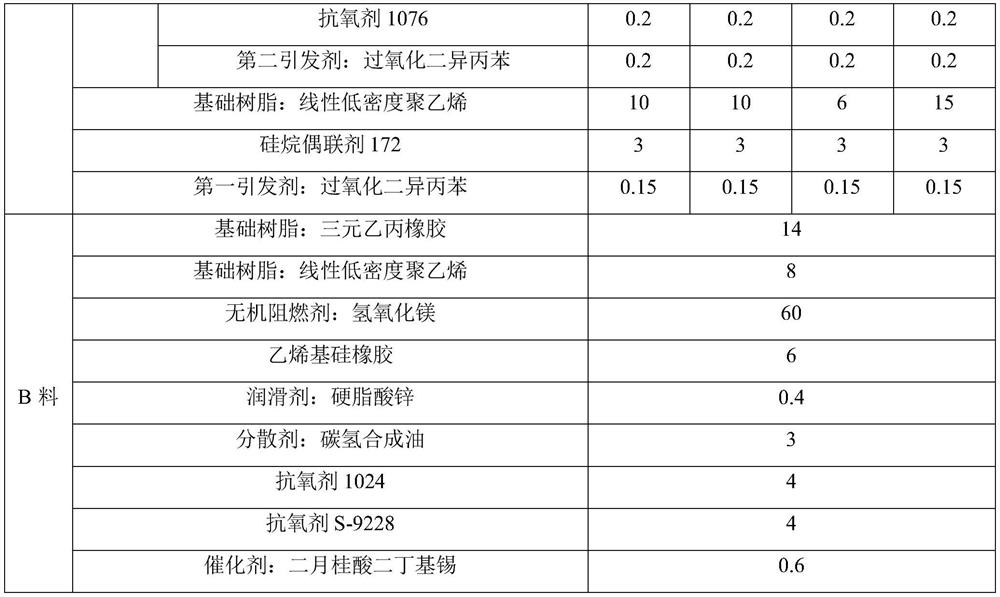

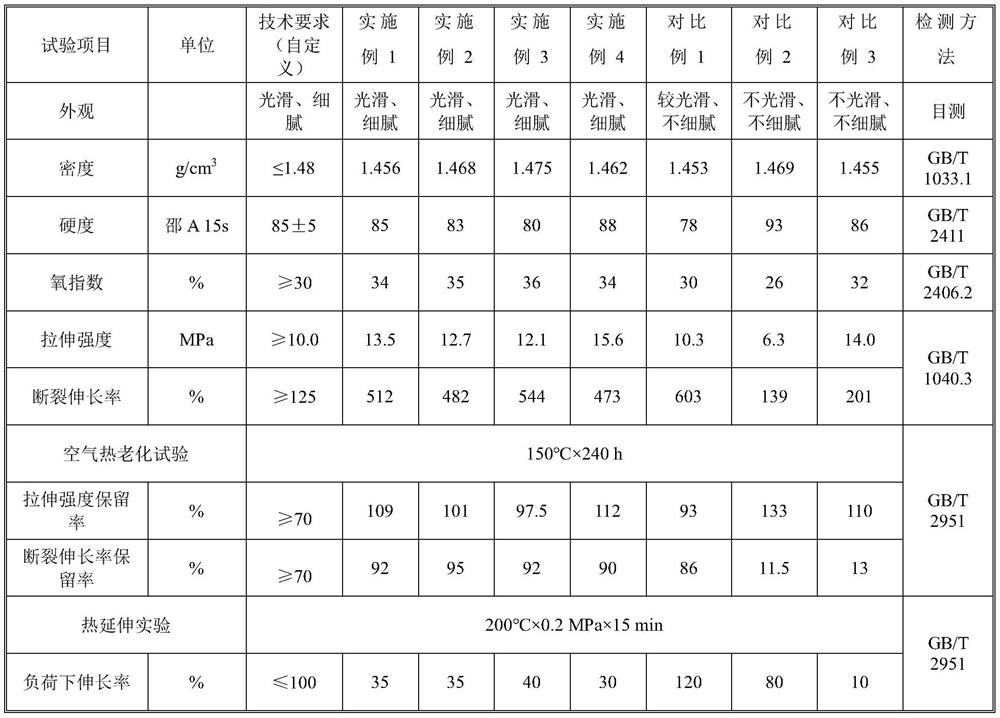

[0053] These embodiments provide a silane self-crosslinking low-smoke halogen-free flame-retardant polyolefin oil-resistant elastomer material, the elastomer material is composed of A material and B material, wherein: the weight ratio of A material and B material is 95: 5. The raw material formulations of material A and material B are shown in Table 1 below.

[0054] Table 1

[0055]

[0056]

[0057] The preparation method of the silane self-crosslinking low-smoke halogen-free flame-retardant polyolefin oil-resistant elastomer material comprises the following steps:

[0058] Mix and banbury the masterbatch components in material A (the temperature is about 200°C), and then extrude and granulate (the extrusion granulation adopts a single-screw extruder, and the extrusion temperature is: barrel 150°C, 155°C, 160°C, 165°C, 170°C; machine neck 170°C; machine head 180°C) to make a masterbatch, mix and graft the masterbatch with the remaining raw materials in material A, the...

PUM

| Property | Measurement | Unit |

|---|---|---|

| melt flow index | aaaaa | aaaaa |

| melt flow index | aaaaa | aaaaa |

| melt flow index | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com