Novel anti-aging agent as well as preparation method and application thereof

An anti-aging agent and a new type of technology, applied in the rubber field, can solve the problems of intolerant migration, intolerant of solvents, volatile antioxidants, etc., and achieve the effects of good anti-aging performance, good stability and avoiding environmental pollution.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

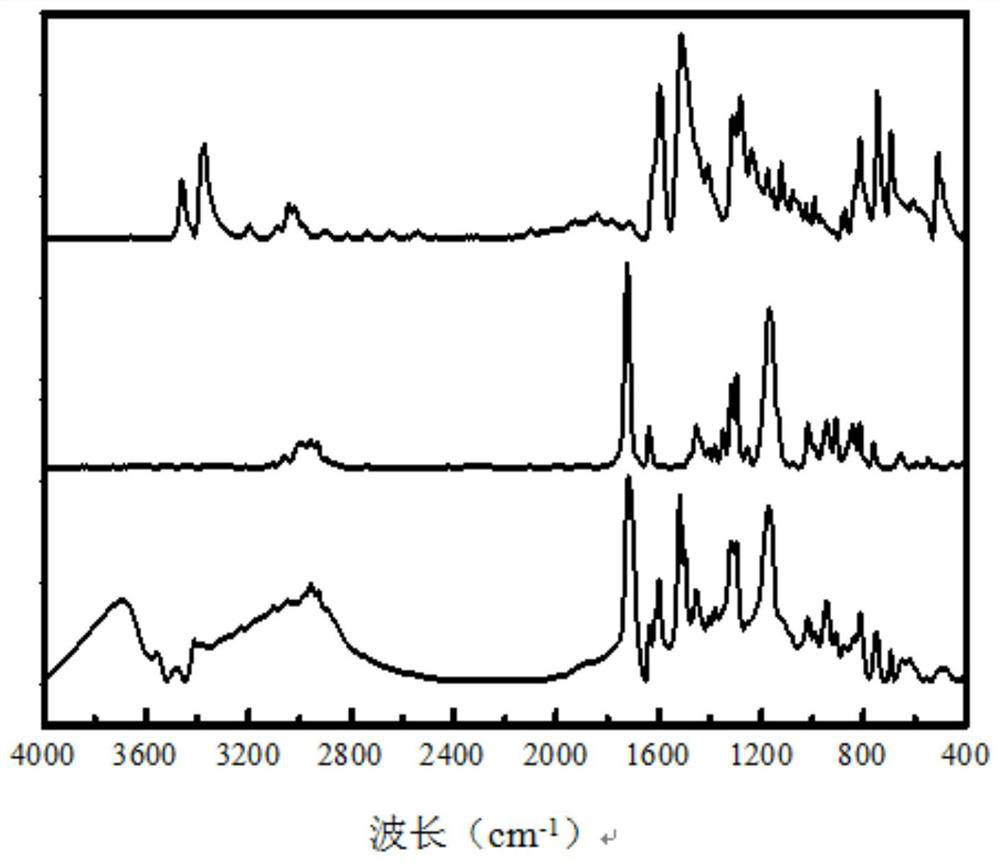

Image

Examples

Embodiment 1

[0046] (1) Preparation of novel antioxidant GMA-g-PPDA

[0047] Glycidyl methacrylate GMA is placed in the reactor, and p-aminodiphenylamine (PPDA) is added at the same time, and the ratio of glycidyl methacrylate GMA to p-aminodiphenylamine PPDA is controlled to be 3:1, and the entire reactor is controlled The temperature is 75°C, keep stirring, continue to react for 3 hours, stop heating.

[0048] (2) Preparation of composite materials

[0049] Take 100 parts of SBR, 40 parts of carbon black N330, 5 parts of zinc oxide, 2 parts of stearic acid, 8 parts of anti-aging agent of Example 1, 1.5 parts of accelerator CZ, 0.5 parts of accelerator DM, and 2 parts of sulfur. The SBR was evenly blended on a two-roll mill, and the obtained mixed rubber was pressed and cut into pieces in a vulcanizer at 150°C, and the properties were tested. The test results are shown in Table 1.

Embodiment 2

[0051] (1) Preparation of novel antioxidant GMA-g-PPDA

[0052]Glycidyl methacrylate GMA is placed in the reactor, and p-aminodiphenylamine (PPDA) is added at the same time, and the ratio of glycidyl methacrylate GMA to p-aminodiphenylamine PPDA is controlled to be 3:1, and the entire reactor is controlled The temperature was 85°C, and the reaction was continued for 3 hours while stirring, and the heating was stopped to obtain a crude product.

[0053] (2) Preparation of composite materials

[0054] Take 100 parts of SBR, 40 parts of carbon black N330, 5 parts of zinc oxide, 2 parts of stearic acid, 8 parts of antioxidant in Example 2, 1.5 parts of accelerator CZ, 0.5 parts of accelerator DM, and 2 parts of sulfur. The SBR was evenly blended on a two-roll mill, and the obtained mixed rubber was pressed and cut into pieces in a vulcanizer at 150°C, and the properties were tested. The test results are shown in Table 1.

Embodiment 3

[0056] (1) Preparation of novel antioxidant GMA-g-PPDA

[0057] Put glycidyl methacrylate GMA in the reactor, and add p-aminodiphenylamine (PPDA) at the same time, control the ratio of glycidyl methacrylate GMA to p-aminodiphenylamine PPDA to be 3:1, and control the entire reactor The temperature is 95°C, keep stirring, continue to react for 3 hours, stop heating.

[0058] (2) Preparation of composite materials

[0059] Take 100 parts of SBR, 40 parts of carbon black N330, 5 parts of zinc oxide, 2 parts of stearic acid, 8 parts of anti-aging agent of Example 1, 1.5 parts of accelerator CZ, 0.5 parts of accelerator DM, and 2 parts of sulfur. The SBR was evenly blended on a two-roll mill, and the obtained mixed rubber was pressed and cut into pieces in a vulcanizer at 150°C, and the properties were tested. The test results are shown in Table 1.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com