Inorganic-organic composite polymer water treatment defluorination flocculant and preparation method thereof

A composite polymer, water treatment technology, applied in water/sludge/sewage treatment, flocculation/sedimentation water/sewage treatment, chemical instruments and methods, etc. It can achieve the effect of obvious fluorine removal effect, diverse structure and high fluorine removal rate.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

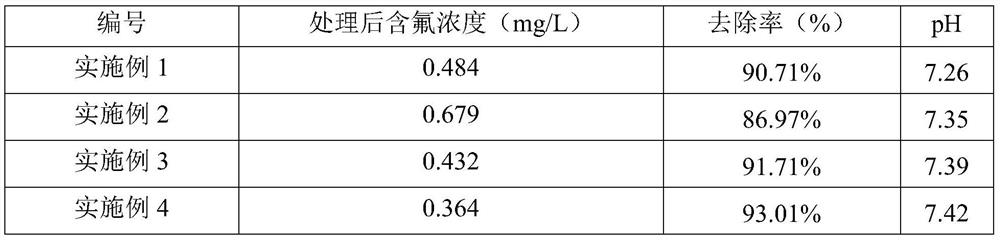

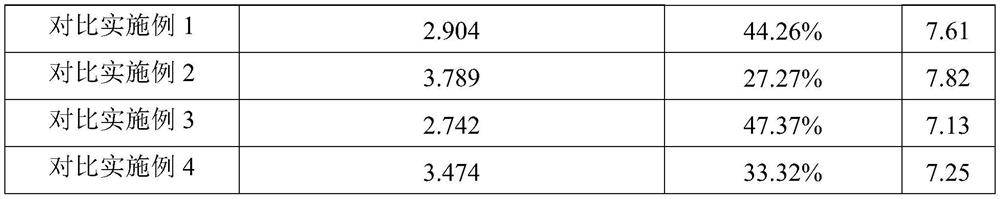

Examples

Embodiment 1

[0032] According to the following steps to prepare the defluorinated flocculant-1, the specific steps are as follows:

[0033] Step 1: Weigh a fixed amount of sodium silicate and dissolve it in quantitative water to obtain a sodium silicate solution with a mass concentration of 5%. Put the sodium silicate solution in a constant temperature water bath, set the constant temperature at 50°C, and stir rapidly for 20 minutes , a colorless transparent solution was obtained, acidified to pH=2.0 by adding dilute hydrochloric acid with a concentration of 1 mol / L, stirred and reacted for 60 min, and solution A was obtained after the reaction was completed.

[0034]Step 2: Weigh a fixed amount of aluminum chloride hexahydrate solid and ferric chloride hexahydrate solid, with a mass ratio of Al / Fe=15:1, dissolve them in an appropriate amount of distilled water, and maintain a mass concentration of about 30%. Slowly add solution A while stirring to ensure that the mass ratio (Al+Fe) / Si=15:...

Embodiment 2

[0038] Prepare the fluorine-removing flocculant-2 according to the following steps, the specific steps are as follows:

[0039] Step 1: Weigh a fixed amount of sodium silicate and dissolve it in quantitative water to obtain a sodium silicate solution with a mass concentration of 5%. Put the sodium silicate solution in a constant temperature water bath, set the constant temperature at 50°C, and stir rapidly for 20 minutes , to obtain a colorless transparent solution, adding dilute hydrochloric acid with a concentration of 1 mol / L to acidify to pH=2.5, stirring and reacting for 60 min, and obtaining solution A after the reaction.

[0040] Step 2: Weigh a fixed amount of aluminum chloride hexahydrate solid and ferric chloride hexahydrate solid, and the mass ratio is Al / Fe=10:1. Dissolve in an appropriate amount of distilled water, and maintain a mass concentration of about 30%. After all of the solution is dissolved, slowly add solution A under constant stirring to ensure that th...

Embodiment 3

[0044] Prepare the fluorine-removing flocculant-3 according to the following steps, the specific steps are as follows:

[0045] Step 1: Weigh a fixed amount of sodium silicate and dissolve it in quantitative water to obtain a sodium silicate solution with a mass concentration of 5%. Put the sodium silicate solution in a constant temperature water bath, set the constant temperature at 50°C, and stir rapidly for 20 minutes , to obtain a colorless transparent solution, adding dilute hydrochloric acid with a concentration of 1mol / L to acidify to pH=2.3, stirring and reacting for 60min, and obtaining solution A after the reaction.

[0046] Step 2: Weigh a fixed amount of aluminum chloride hexahydrate solid and ferric chloride hexahydrate solid, with a mass ratio of Al / Fe=20:1. Dissolve in an appropriate amount of distilled water, and maintain a mass concentration of about 30%. After all of the solution is dissolved, slowly add solution A under constant stirring to ensure that the m...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - Generate Ideas

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com