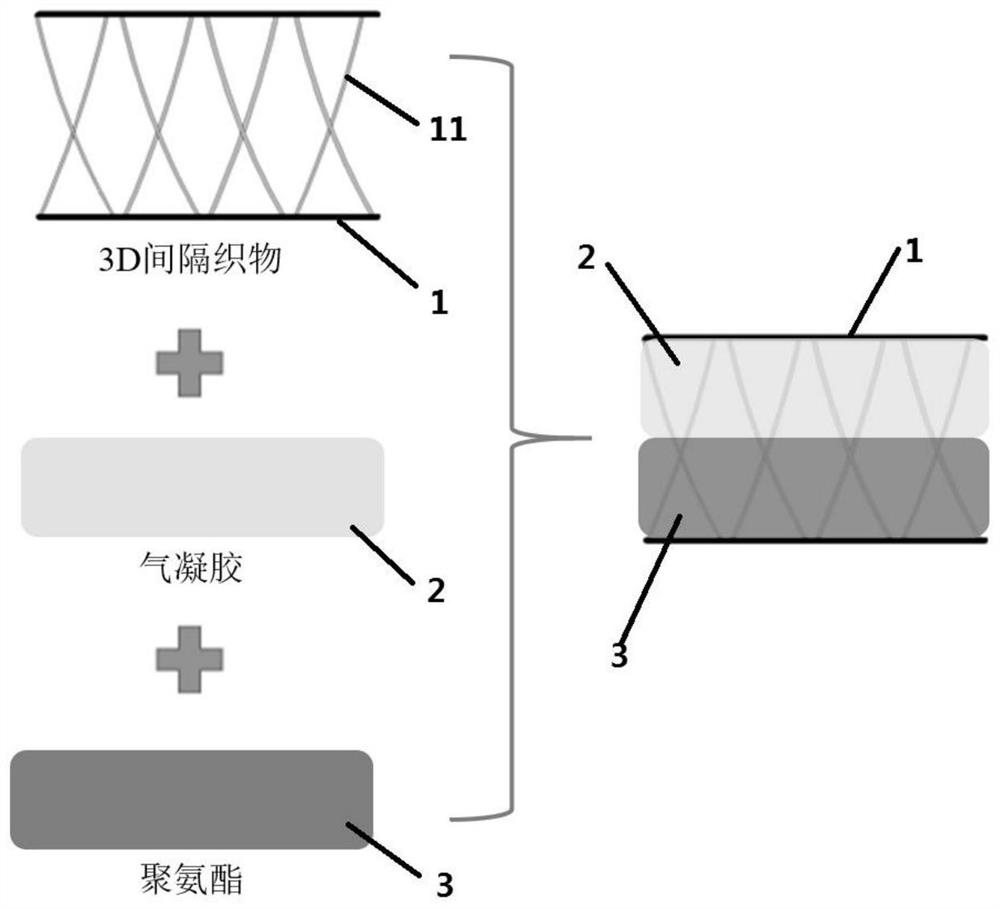

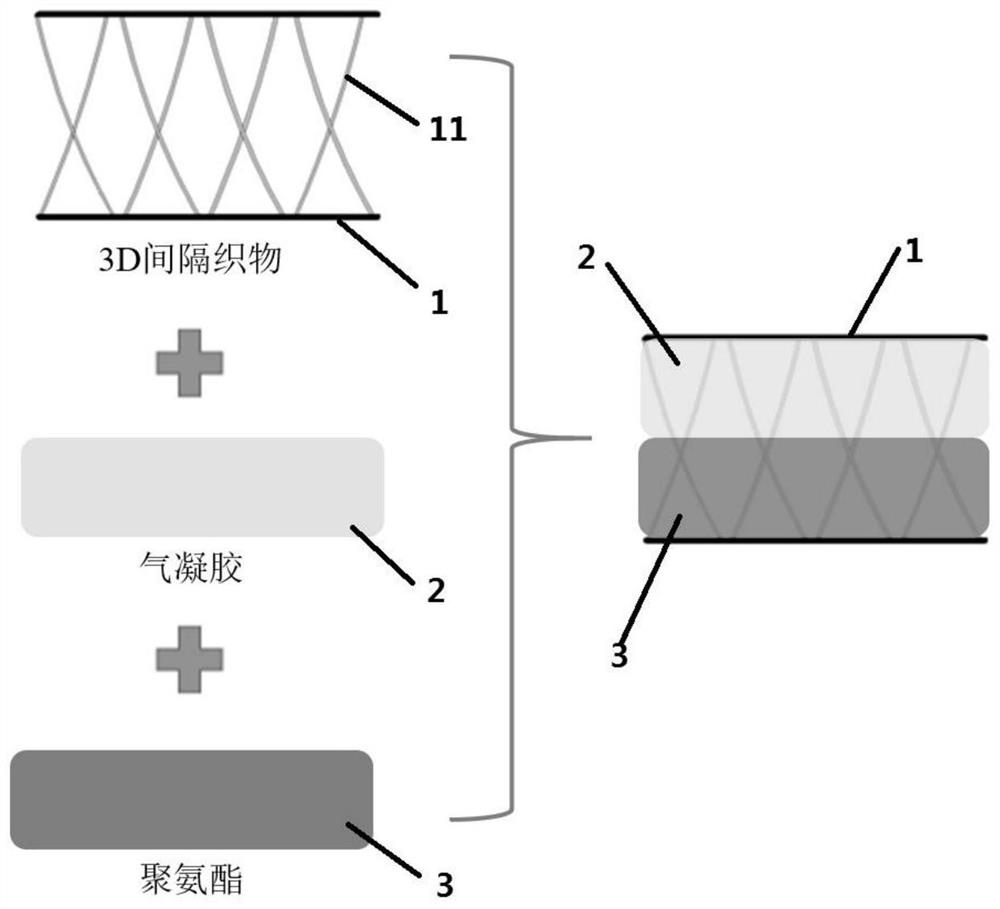

Laminated impedance change composite structure sound absorption material and preparation method and application thereof

A technology of sound-absorbing material and composite structure, which is applied in chemical instruments and methods, sound-producing equipment, layered products, etc. The effect of short cycle and simple process

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0039] A method for preparing a laminated impedance-changing composite structure sound-absorbing material, comprising the following steps:

[0040] Step 1: The three-dimensional spacer fabric is woven by a double-needle bed Raschel warp knitting machine with a total of 6 bars from GB1 to GB6, in which the upper surface and the lower surface of the fabric are warp-knitted spacer fabrics with knitting chains and weft insertion, GB2 The yarn on GB5 is 300D / 96F polyester multifilament, the carbon fiber tow on GB1 and GB6, and the polyester monofilament with a diameter of 0.2mm on GB3 and GB4; The front needle bed weaves the upper surface of the three-dimensional spacer fabric, the two bars GB5 and GB6 knit the lower surface of the fabric on the rear needle bed, and the two bars GB3 and GB4 carry the spacer yarns, knitting alternately on the front and rear needle beds The upper and lower surfaces of the three-dimensional spacer fabric are connected with spacer wires to form a three...

Embodiment 2

[0047] A method for preparing a laminated impedance-changing composite structure sound-absorbing material, comprising the following steps:

[0048]Step 1: The three-dimensional spacer fabric is woven by a double-needle bed Raschel warp knitting machine with a total of 6 bars from GB1 to GB6, in which the upper surface and the lower surface of the fabric are warp-knitted spacer fabrics with knitting chains and weft insertion, GB2 The yarn on GB5 is 300D / 96F polyester multifilament, the carbon fiber tow on GB1 and GB6, and the polyester monofilament with a diameter of 0.2mm on GB3 and GB4; The front needle bed weaves the upper surface of the three-dimensional spacer fabric, the two bars GB5 and GB6 knit the lower surface of the fabric on the rear needle bed, and the two bars GB3 and GB4 carry the spacer yarns, knitting alternately on the front and rear needle beds The upper and lower surfaces of the three-dimensional spacer fabric are connected with spacer wires to form a three-...

Embodiment 3

[0055] A method for preparing a laminated impedance-changing composite structure sound-absorbing material, comprising the following steps:

[0056] Step 1: The three-dimensional spacer fabric is woven by a double-needle bed Raschel warp knitting machine with a total of 6 bars from GB1 to GB6, in which the upper surface and the lower surface of the fabric are warp-knitted spacer fabrics with knitting chains and weft insertion, GB2 The yarn on GB5 is 300D / 96F polyester multifilament, the carbon fiber tow on GB1 and GB6, and the polyester monofilament with a diameter of 0.2mm on GB3 and GB4; The front needle bed weaves the upper surface of the three-dimensional spacer fabric, the two bars GB5 and GB6 knit the lower surface of the fabric on the rear needle bed, and the two bars GB3 and GB4 carry the spacer yarns, knitting alternately on the front and rear needle beds To connect the upper and lower surfaces of the three-dimensional spacer fabric with spacer wires to form a three-di...

PUM

| Property | Measurement | Unit |

|---|---|---|

| thickness | aaaaa | aaaaa |

| density | aaaaa | aaaaa |

| diameter | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - Generate Ideas

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com