Automatic control device for industrial robot

An automatic control and industrial robot technology, which is applied in the direction of manipulators, manufacturing tools, chucks, etc., can solve the problems of easy wear, rough outer peripheral surface of the driving column, and unsmooth sliding of the driving column, and achieve better results.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

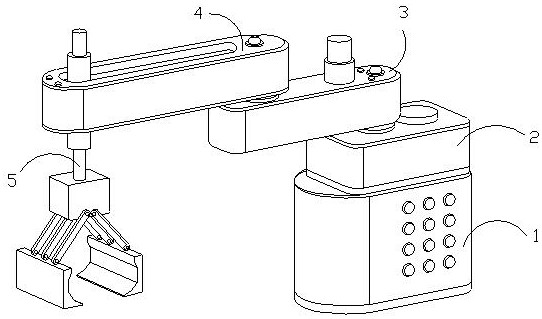

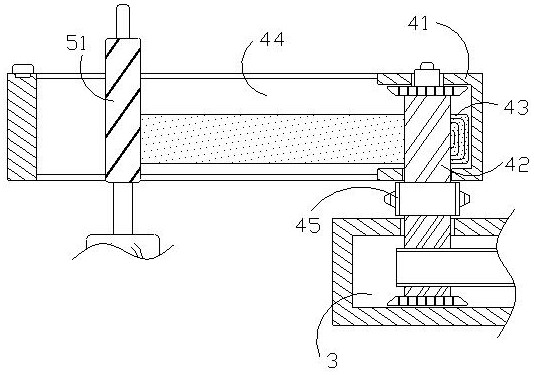

[0029] as attached figure 1 To attach Figure 5 Shown:

[0030] The invention provides an automatic control device for an industrial robot, the structure of which is provided with a control station 1, a drive transfer box 2, a transmission frame 3, an activity control device 4, and a grabbing device 5, and the drive transfer box 2 is installed above the control station 1 , the transmission frame 3 is connected to the top of the drive case 2 and is movably matched, the activity control device 4 is in transmission cooperation with the front end of the transmission frame 3 , and the grasping device 5 is slidably matched with the inside of the activity control device 4 .

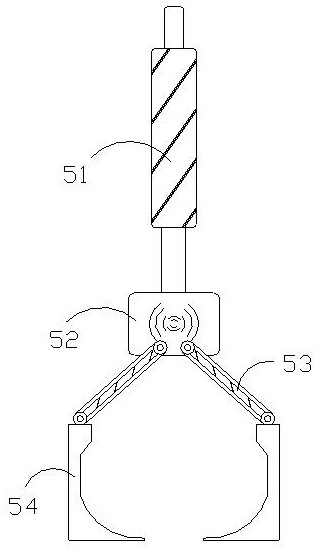

[0031] The grasping device 5 is provided with a driving column 51, an induction machine 52, a matching rod 53, and a robot gripper 54. The driving column 51 is slidingly matched with the inside of the movable control device 4, and the induction machine 52 is fixedly connected to the driving column 51. At the l...

Embodiment 2

[0037] as attached Figure 6 to attach Figure 7 Shown:

[0038] Wherein, the connecting frame a2 is provided with an arc frame a21, a swing rod a22, a spring steel a23, a pulling block a24, and a solid block a25. Both ends of the arc frame a21 are hingedly connected with the solid block a25, and the swing rod a22 One end is hingedly connected to the solid block a25, the spring steel a23 is slidingly fitted between the swing rods a22, the pulling block a24 is connected between the ends of the swing rod a22, and the arc frame a21 is arc-shaped and has a telescopic The swing rod a22 can be pivoted and folded, and the pulling block a24 is a block made of butadiene rubber, which has good traction. The swing rod a22 is made of spring steel a23 and the pulling block a24 With the cooperation of the spacer, the spacing can be changed, which is convenient for the overall inclination of the swing rod a22 to change, and the force applied to the arc frame a21 is different, which is cond...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - Generate Ideas

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com