Special ceramic tube inner wall polishing device

A technology for polishing devices and special ceramics, which is applied in the direction of grinding drive devices, grinding/polishing equipment, surface polishing machine tools, etc. It can solve the problems of inconvenient use of the device and the inability to ensure continuous and stable pressure between sandpaper and polished parts, and achieve Ease of use

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

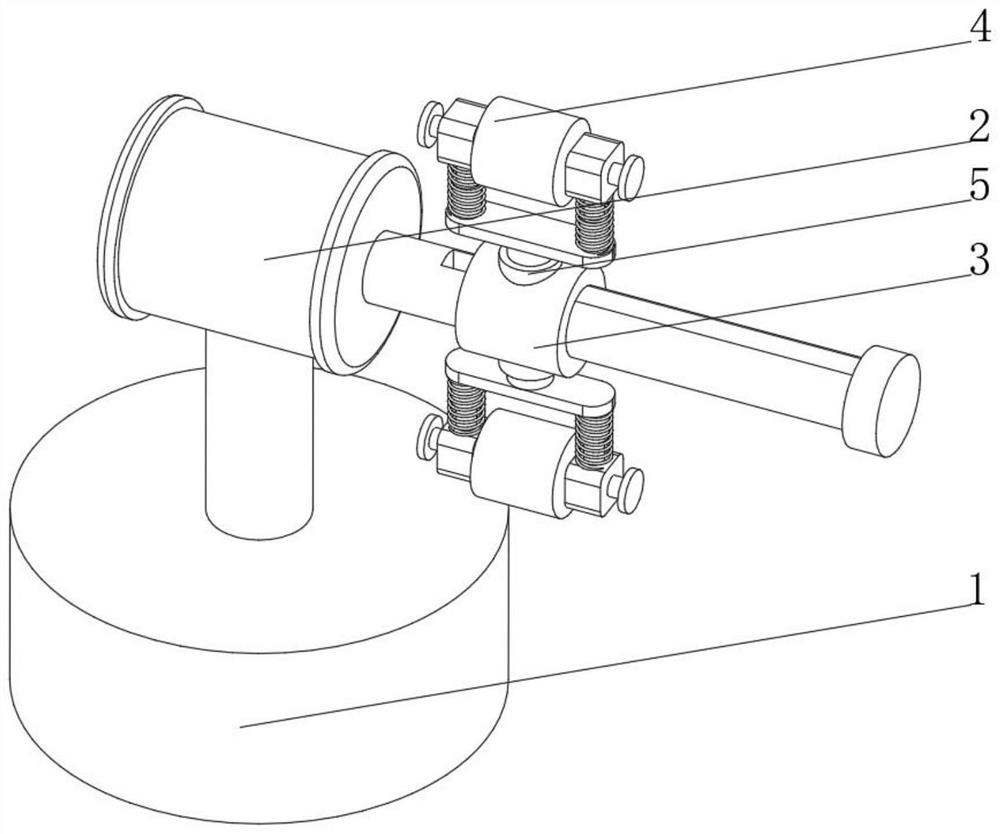

[0036] see Figure 1-2 , the present invention provides a technical solution: a special ceramic tube inner wall polishing device, specifically comprising:

[0037] A fixed base 1, the top of the fixed base 1 is fixedly connected with a drive motor 2 through a bracket, and the drive shaft of the drive motor 2 is fixedly connected with a mobile device 3;

[0038]Polishing device 4, the bottom of the polishing device 4 is fixedly connected with the mobile device 3 through the electric telescopic rod 5, and the top and bottom of the mobile device 3 are equipped with a polishing device 4;

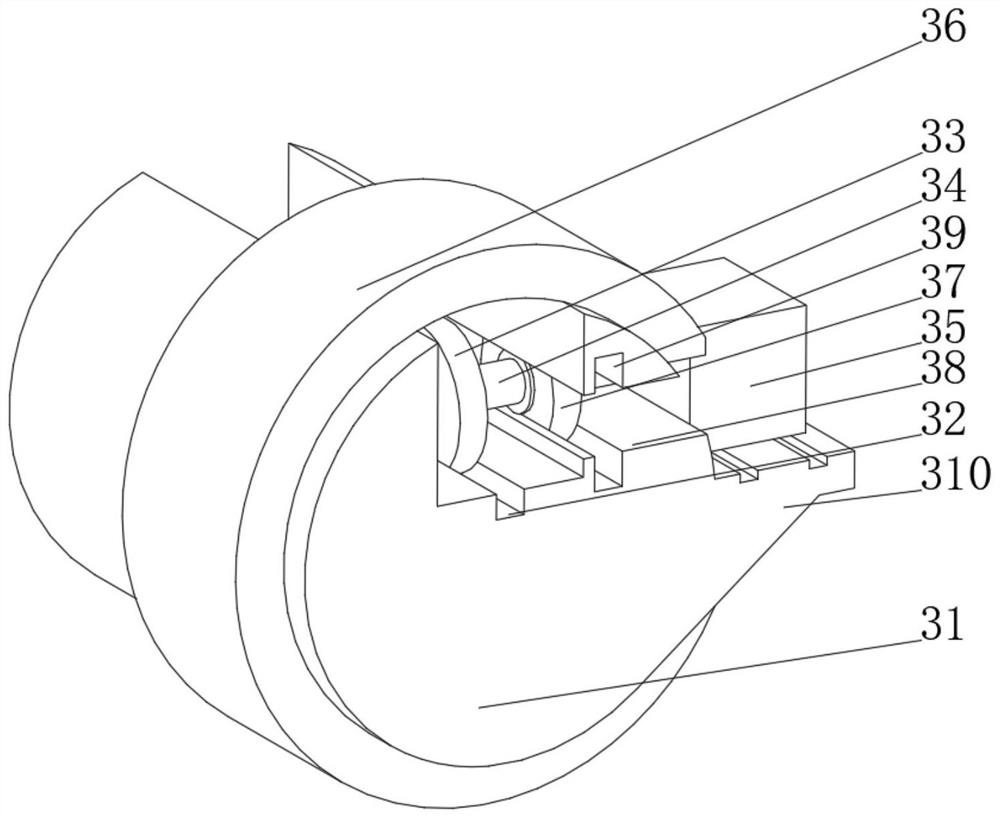

[0039] The mobile device 3 includes:

[0040] Guide rod 31, the top of the guide rod 31 is provided with a tooth groove 32, the inner wall of the tooth groove 32 is meshed with a gear 33, one side of the gear 33 is fixedly connected with a connecting rod 34, and the end of the connecting rod 34 away from the gear 33 runs through the guide rod 31 and extends to The outside of the guide rod 31; ...

Embodiment 2

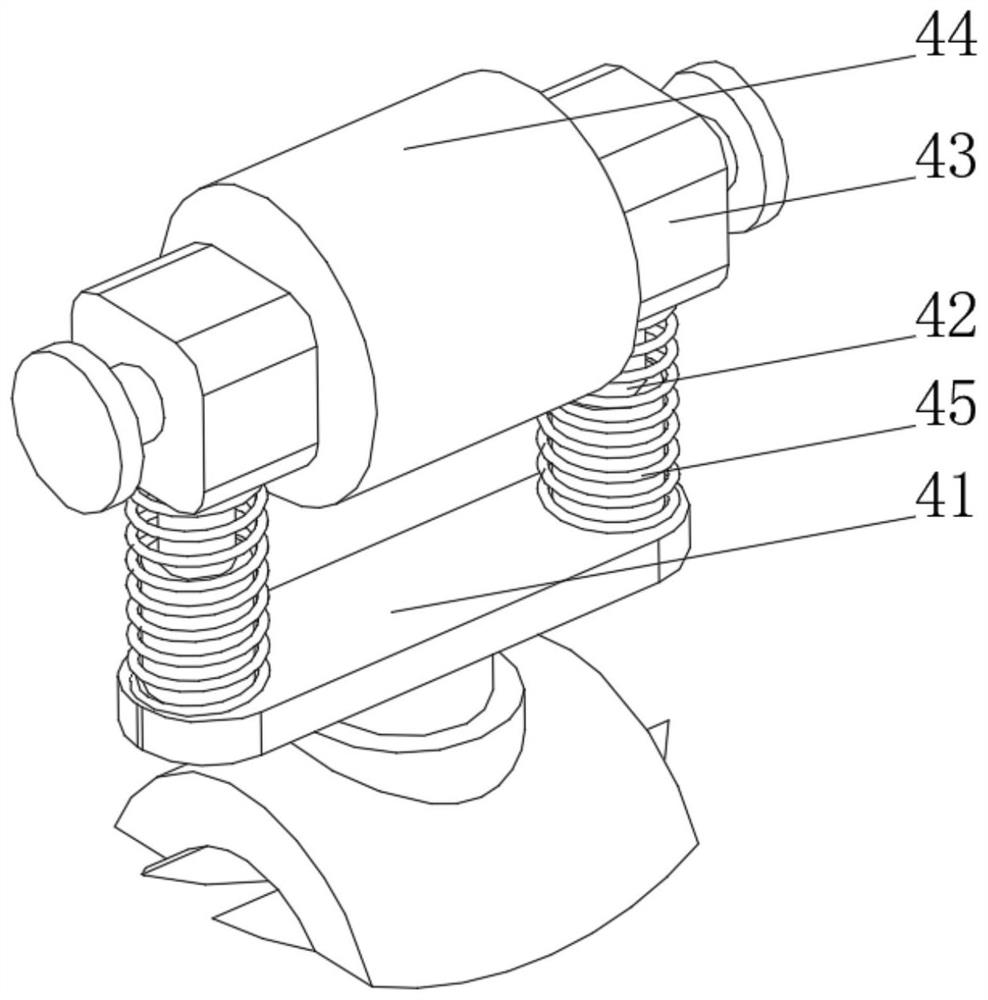

[0045] see Figure 1-3 On the basis of Embodiment 1, the present invention provides a technical solution: the polishing device 4 includes a fixed plate 41, the two ends of the fixed plate 41 are rotatably connected with a telescopic rod 42, and the top of the telescopic rod 42 is rotatably connected with an adjustment device 43, and the adjustment device One side of 43 is provided with a polishing device 44, the fixed plate 41 is connected with the adjusting device 43 by a return spring 45, and the return spring 45 is sleeved on the outside of the telescopic rod 42. When the polishing device 4 rotates, the polishing device 44 is under the action of centrifugal force. Closely attached to the inner wall of the pipeline, the inner wall of the pipeline is polished, and the two ends of the telescopic rod 42 are respectively connected to the fixed plate 41 and the adjustment device 43 in rotation. Long, drive the grinding device 44 to stick on the inclined pipeline inner wall, which...

Embodiment 3

[0047] see Figure 1-5 On the basis of Embodiment 1 and Embodiment 2, the present invention provides a technical solution: the adjustment device 43 includes an adjustment disc 431, one side of the adjustment disc 431 is penetrated and fixedly connected with a ratchet mechanism 432, and the rotating disc inside the ratchet mechanism 432 is a One end of the adjusting rod 433 extends to the inside of the adjusting disc 431 and is fixedly connected with a rotating disc 434. One side of the rotating disc 434 is connected with a rotating rod 435 through a bearing for rotation. Between the rotating rod 435 and the adjusting disc 434 A clockwork spring 436 is arranged between them, the bottom of the adjusting disc 431 is fixedly connected with the top of the telescopic rod 42, the end of the rotating rod 435 away from the rotating disc 434 is fixedly connected with the polishing device 44, and the end of the adjusting rod 443 away from the rotating disc 434 is provided with a handle. ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com