Manufacturing method of N-type battery boron expansion SE structure

A manufacturing method and N-type technology, applied in the field of solar cells, can solve problems such as difficulty in realization, and achieve the effects of improving conversion efficiency, improving open circuit voltage, and improving fill factor

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

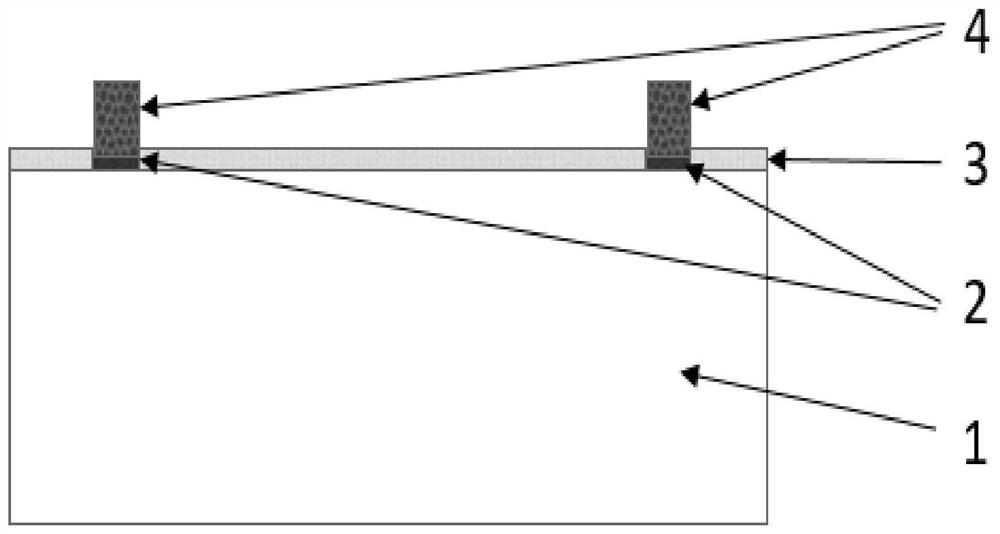

Image

Examples

Embodiment 1

[0037] A method for manufacturing an N-type battery boron-enhanced SE (selective emitter, referred to as SE) structure, comprising the following steps:

[0038] (1) Insert the N-type silicon chip after cleaning and making texture vertically or horizontally into the quartz crystal boat of the low-pressure diffusion furnace, and put it into the furnace tube; The surface produces a pyramid-like structure. In this embodiment, the conventional steps in the prior art are used for the washing and making of texture, and no improvement is made in this application.

[0039] (2) After heating up to a diffusion temperature of 880°C and stabilizing for 3 minutes, perform vacuuming and leak detection steps;

[0040] (3) The temperature is kept at the diffusion temperature of 880°C, nitrogen and oxygen are introduced at a constant pressure of 100mbar, the flow of nitrogen is controlled at 2000sccm, the flow of oxygen is controlled at 500sccm, and the time is 5min, a thin layer of silicon ox...

Embodiment 2

[0052] A method for manufacturing an N-type battery boron-enhanced SE (selective emitter, referred to as SE) structure, comprising the following steps:

[0053] (1) Insert the N-type silicon chip after cleaning and making texture vertically or horizontally into the quartz crystal boat of the low-pressure diffusion furnace, and put it into the furnace tube; The surface produces a pyramid-like structure. In this embodiment, the conventional steps in the prior art are used for the washing and making of texture, and no improvement is made in this application.

[0054] (2) After heating up to a diffusion temperature of 900°C and stabilizing for 2 minutes, perform vacuuming and leak detection steps;

[0055] (3) The temperature is kept at the diffusion temperature of 900°C, nitrogen and oxygen are introduced at a constant pressure of 120mbar, the flow of nitrogen is controlled at 2000sccm, the flow of oxygen is controlled at 700sccm, and the time is 3min, a thin layer of silicon ox...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com