ERT sensor for wear detection of high-speed rail contact line

A technology of contact wires and sensors, applied in the field of ERT sensors, can solve the problems of low detection efficiency and reliability of high-speed rail contact wires, reduce work intensity, etc., and achieve the goal of solving low detection efficiency and reliability, reducing work intensity, and ensuring safe operation Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

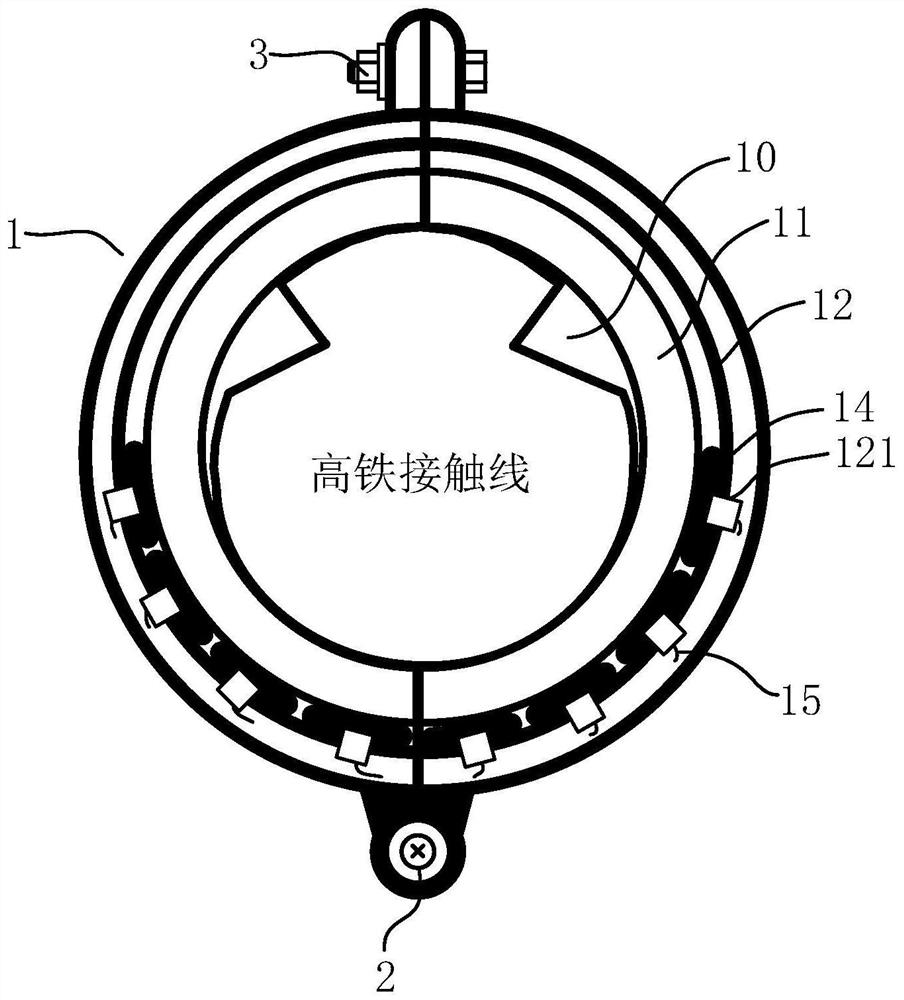

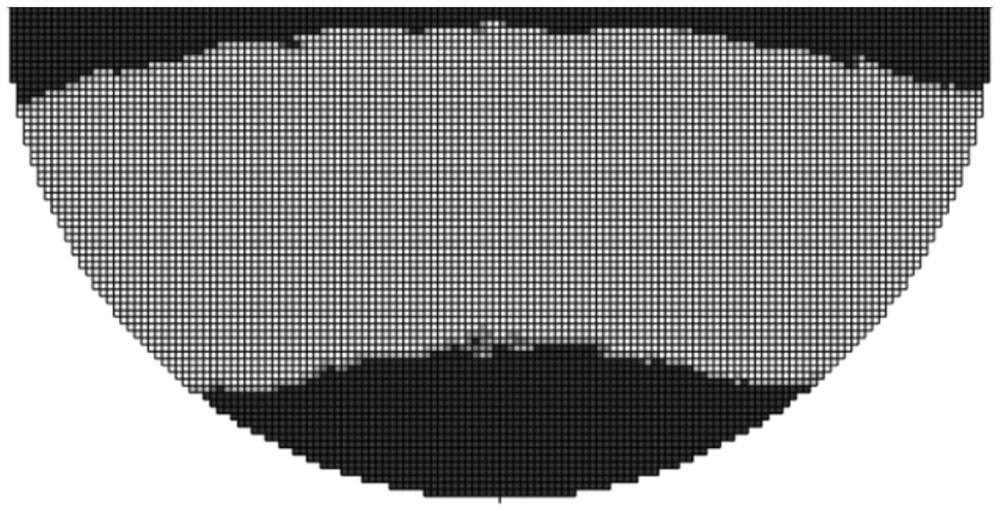

[0048] Such as figure 1 As shown, the ERT sensor used for contact wire wear detection in this embodiment includes an annular sensor body 1 with a contact wire placement inner hole 10 in the middle, and the annular sensor body 1 includes an elastic conductive ring 11 and an insulating pipe 12 arranged in sequence from the inside to the outside. And shielding cover 13, be provided with electrode assembly between elastic conductive ring 11 and insulating pipe 12, electrode assembly comprises the electrode 14 (in the present embodiment, be 8 in the present embodiment) that the quantity that is arranged at intervals along the circumferential direction of elastic conductive ring 11 outer wall is more than six , the quantity can be adjusted as needed). In this embodiment, the conductivity change caused by the wear of the contact wire can be used to directly image the cross section of the contact wire, and the wear amount of the contact wire can be detected intuitively through imaging...

Embodiment 2

[0083] This embodiment is basically the same as Embodiment 1, where the main difference is: in this embodiment, the excitation / measurement lead 15 is connected to the part where the electrode 14 protrudes from the via hole 121 on the insulating pipe 12 and connected from the insulating pipe 12 and the shielding cover. The gaps between 13 are drawn out. Compared with the first embodiment, the structure of the electrode 14 is simpler, which is convenient for processing.

Embodiment 3

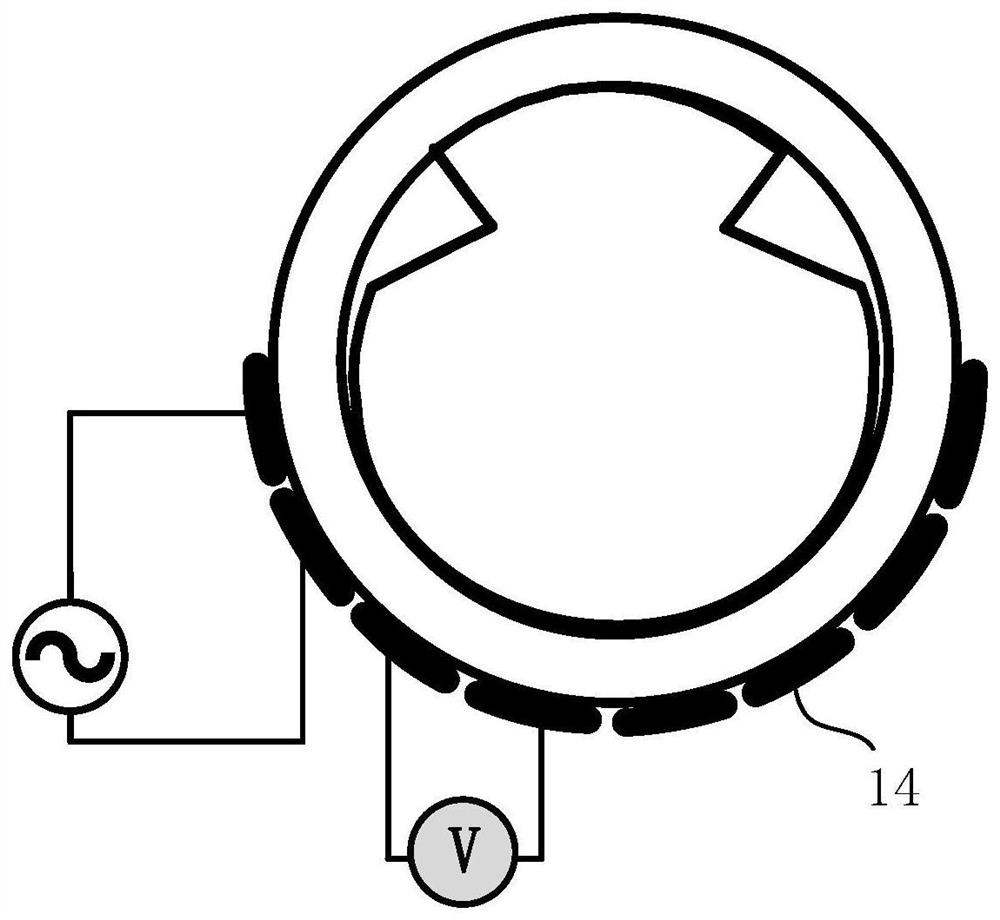

[0085] This embodiment is a further integration of the ERT sensor used for contact line wear detection in the first embodiment. Such as Figure 5 As shown, the present embodiment provides a detection system for contact wire wear, including a switch unit 4, a signal acquisition and conditioning circuit 5, a processing unit 6, a microcontroller 7, a DDS sine wave generator 8 and the first embodiment For the ERT sensor used in contact wire wear detection, the switch unit 4 includes a measuring electrode gating switch 41 and an excitation electrode gating switch 42, the measuring electrode gating switch 41, the exciting electrode gating switch 42 and the control terminal of the DDS sine wave generator 8 Link to each other with microcontroller 7 respectively, the output end of DDS sine wave generator 8 links to each other with each electrode 14 of ERT sensor through exciting electrode gating switch 42, and each electrode 14 of ERT sensor is through measuring electrode gating switch...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com