Grouting and water plugging reinforcement material for water-rich bedrock tunnel leakage water and application of grouting and water plugging reinforcement material

A technology for reinforcing materials and seepage water, applied in tunnels, tunnel linings, wellbore linings, etc., can solve problems such as inability to achieve drainage effect, unclear water seepage location, and shotcrete offset, so as to improve treatment capacity and service life. , Improve the treatment level, the effect of low water seepage coefficient

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

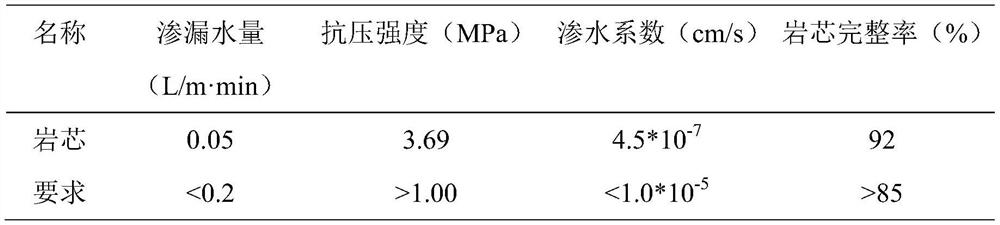

Embodiment 1

[0016] In this embodiment, the water-rich bedrock tunnel seepage water grouting water blocking reinforcement material is composed of 30% CFB fly ash, 5% Mali powder, 15% cement, and 50% water. Firstly, CFB fly ash, cement, and water are evenly stirred by a high-speed vortex pulper at 300rmp for 1min to make them evenly mixed; then add Ma Lisan and evenly stirred by a high-speed vortex pulper at 200rmp for 30s to obtain water-rich bedrock Tunnel seepage water grouting water plugging reinforcement material.

[0017] The method of using the leakage water grouting water blocking reinforcement material for the above-mentioned water-rich bedrock tunnel: use a graduated container to collect and measure, install it on the inner surface of the tunnel for the specified measurement, introduce the leakage water into the measurement container, and then calculate 24h leakage water volume, and determine the location (coordinates) of the leakage water; quincunx-shaped drill holes are arranged...

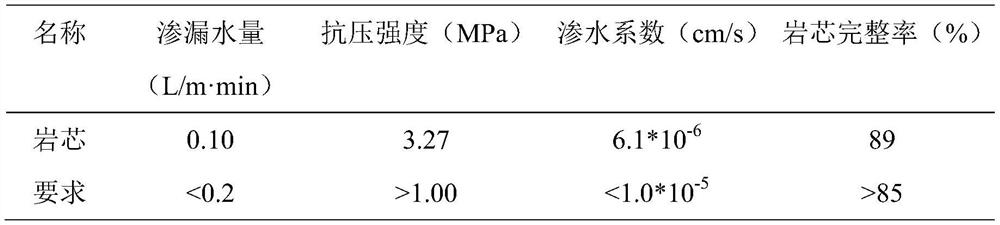

Embodiment 2

[0022] In this embodiment, the water-rich bedrock tunnel seepage water grouting water blocking reinforcement material is composed of 40% CFB fly ash, 5% Mali powder, 5% cement, and 50% water. Firstly, CFB fly ash, cement, and water are evenly stirred by a high-speed vortex pulper at 300rmp for 1min to make them evenly mixed; then add Ma Lisan and evenly stirred by a high-speed vortex pulper at 200rmp for 30s to obtain water-rich bedrock Tunnel seepage water grouting water plugging reinforcement material.

[0023] The method of using the leakage water grouting water blocking reinforcement material for the above-mentioned water-rich bedrock tunnel: use a graduated container to collect and measure, install it on the inner surface of the tunnel for the specified measurement, introduce the leakage water into the measurement container, and then calculate 24h leakage water volume, and determine the location (coordinates) of the leakage water; quincunx-shaped drill holes are arranged ...

Embodiment 3

[0028] In this embodiment, the water-rich bedrock tunnel seepage water grouting water blocking reinforcement material is composed of 40% CFB fly ash, 10% cement, and 50% water. Mix CFB fly ash, cement, and water with a high-speed vortex pulper at 300rmp for 1 minute to make them evenly mixed to obtain water-rich bedrock tunnel leakage water grouting and water blocking reinforcement materials.

[0029] The method of using the leakage water grouting water plugging reinforcement material for the above-mentioned water-rich bedrock tunnel: use a square frame of a specified size with a sealing edge, install it on the inner surface of the tunnel for specified measurement, and introduce the leakage water into the measurement container , and then calculate the amount of water leakage in 24 hours, and determine the position (coordinates) of water leakage; arrange plum blossom-shaped drilling holes at 10cm in the leakage water area (cracks or cracks) of the tunnel working face, and then a...

PUM

| Property | Measurement | Unit |

|---|---|---|

| compressive strength | aaaaa | aaaaa |

| compressive strength | aaaaa | aaaaa |

| compressive strength | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com