Device and method for producing aluminum-based intermediate alloy through aluminothermic reduction method

An intermediate alloy and reduction method technology, which is applied in the field of metal smelting, can solve problems such as uneven mixing of reactants, and achieve the effects of improving alloy quality, saving energy, and speeding up the reaction rate

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

specific Embodiment 1

[0062] Specific embodiment one of the method for producing an aluminum-based master alloy by the aluminothermic reduction method of the present invention is:

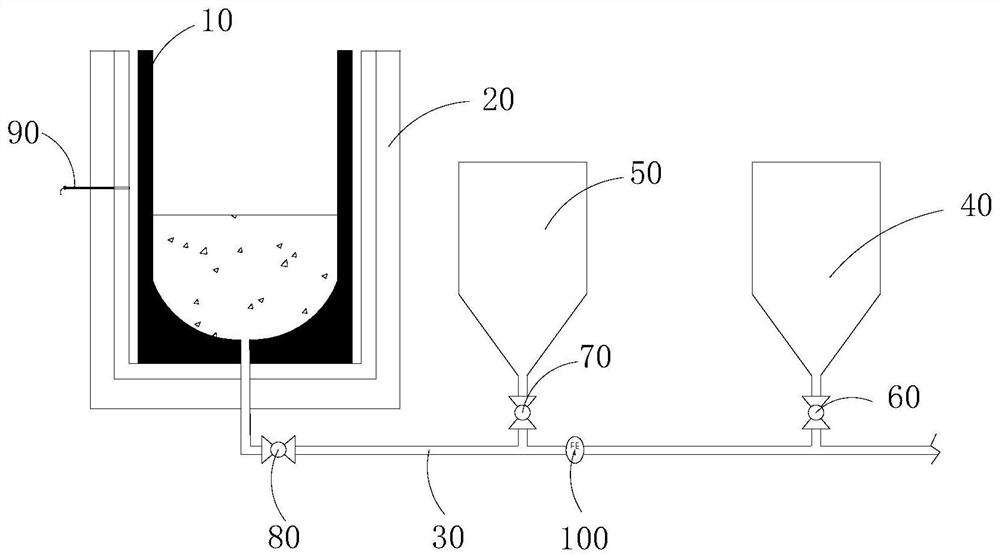

[0063] reduction oxide material gas The first default flow second preset temperature third preset temperature Second default flow Oxide particle size The third default flow metal aluminum V 2 o 5

[0064] Concrete reaction steps: after putting a certain weight of metal aluminum into the reaction crucible, open the first valve 60 and the third valve 80 and start to feed hydrogen (the gas fed in this embodiment is the reducing gas hydrogen), and control the flowmeter 100 to show the number 0.1m 3 / min, turn on the heating furnace to heat up, after the metal aluminum liquefies, within the first preset time period, the thermocouple display reaches the second preset temperature of 850°C and maintains this temperature, within the second preset time period, reset the second preset temperatur...

specific Embodiment 2

[0065] The specific embodiment two of the method for producing aluminum base master alloy by aluminothermic reduction method of the present invention is:

[0066] reduction oxide material gas The first default flow second preset temperature third preset temperature Second default flow Oxide particle size The third default flow Liquid metal aluminum MoO 3

[0067] Concrete reaction steps: after putting a certain weight of metal aluminum into the reaction crucible, open the first valve 60 and the third valve 80 and start to feed helium (the gas that is passed into in this embodiment is the inert gas helium), and control the flow meter 100 The indication is 0.5m 3 / min, turn on the heating furnace to heat up, after the metal aluminum liquefies, within the first preset time period, the thermocouple display reaches the second preset temperature of 900°C and maintains this temperature, within the second preset time period, reset the second preset te...

specific Embodiment 3

[0068] The specific embodiment three of the method for producing aluminum-based master alloy by aluminothermic reduction method of the present invention is:

[0069] reduction oxide material gas The first default flow second preset temperature third preset temperature Second default flow Oxide particle size The third default flow Liquid metal aluminum V 2 o 5

[0070] Concrete reaction steps: after putting a certain weight of metal aluminum into the reaction crucible, open the first valve 60 and the third valve 80 and start to feed hydrogen (the gas fed in this embodiment is the reducing gas hydrogen), and control the flowmeter 100 to show the number 1m 3 / min, turn on the heating furnace to heat up, after the metal aluminum liquefies, within the first preset time period, the thermocouple display reaches the second preset temperature of 850°C and maintains this temperature, within the second preset time period, reset the second preset temper...

PUM

| Property | Measurement | Unit |

|---|---|---|

| particle size | aaaaa | aaaaa |

| particle size | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com